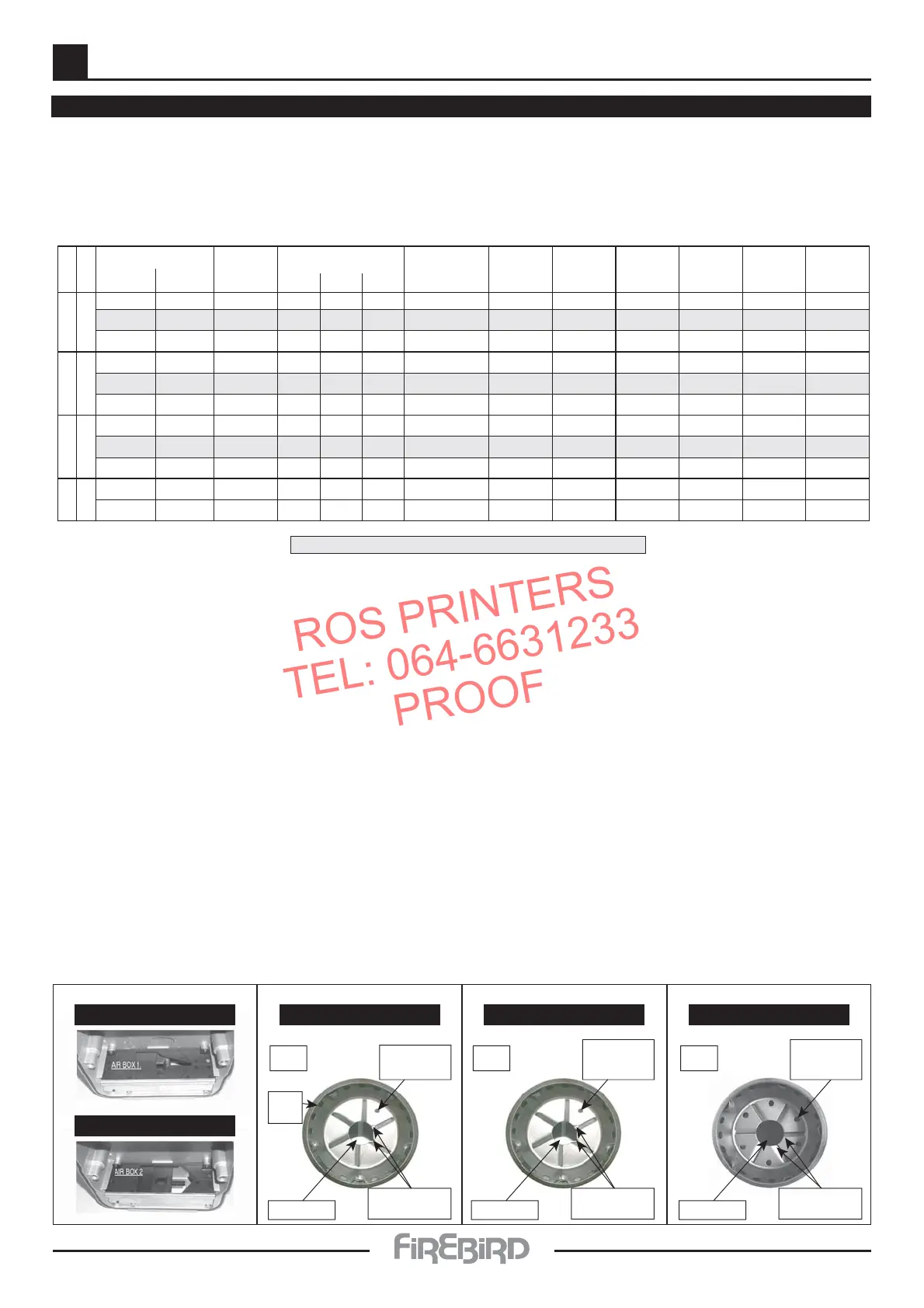

Riello RDB 2.2 Range Burner Settings (D).

Variations in nozzle throughput, flue type & draught, oil viscosity etc. may give results differing from these

laboratory performance figures. These settings were carried out using a conventional flue.

DIESEL SETTINGS FOR FIREBIRD C BOILER RANGE USING RDB 2.2 & 4.2 BURNERS

The burner nozzle, pump pressure and air setting may have to be changed from the factory setting to suite sight conditions.

The above settings were carried out on a Firebird Condensing Boiler with 2 mitres of vertical balanced flue. The ambient air was

averaging around 20˚C. Allowances should also be allowed for the viscosity of the oil and the tolerance of the nozzles.

These settings are a guide and should only be used as such. A flue gas analyser must be used when fine tuning a burner to a boiler.

When using this chart on a burner fitted to a standard efficient boiler air setting may vary.

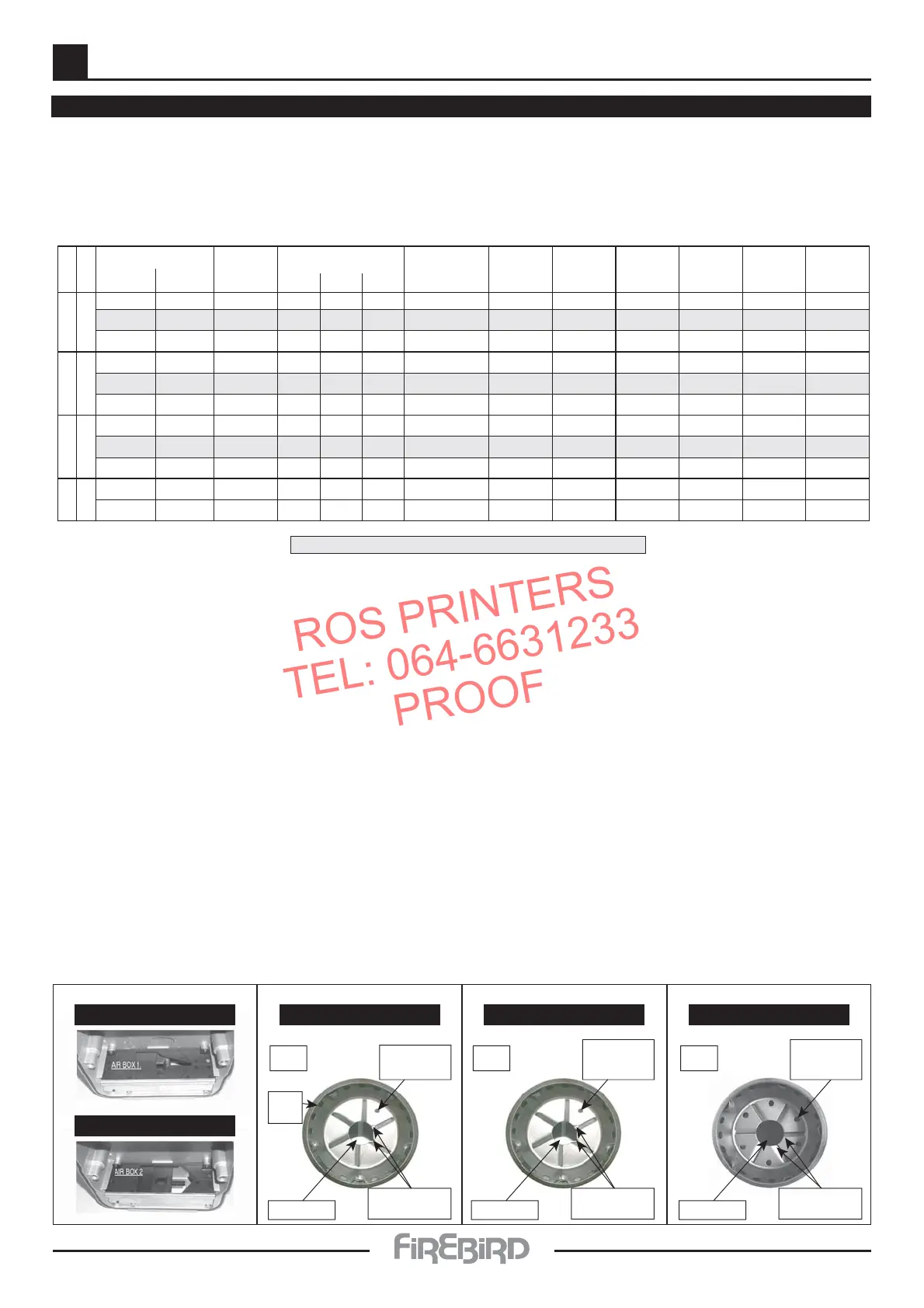

Steps in Commissioning a Burner in a Firebird Boiler.

1. Check Nozzle to required output.

2. Is the correct Burner Head fitted to the burner for the required output?

3. Set air damper from the guide above for the desired output.

4. Check the pump pressure.

5. Set Boiler thermostat to minimum and allow boiler to heat up before carrying out a Flue gas analysis.

6. Check Flue gasses with a smoke gun before taking using Flue gas analyser.

7. Proceed with Flue gas analysis, adjust air damper to get desired CO2%.

8. Print a record of analysis result.

Loading...

Loading...