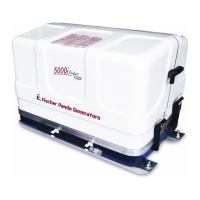

Why is my Fischer Panda Portable Generator not starting?

- RruizthomasJul 29, 2025

Your Fischer Panda Portable Generator might fail to start due to several reasons: * The starter battery may be switched off. In this case, check the position of the battery switch and switch it on, if installed. * The starter battery voltage might be insufficient, indicating a weak battery. Inspect the battery terminals and cables for a good electrical connection, checking for corrosion or tattered wires. * The starting current could be disrupted. During a normal start, the battery voltage drops to 11V with a fully charged battery. If the voltage doesn't drop during starting, the electrical connection is faulty. If the battery voltage drops below 11V, the battery is discharged.