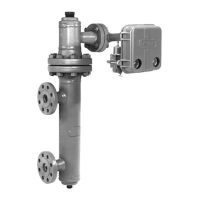

2502 Series

21

Note

Beam overtravel can jam the flapper

against the nozzle if the following step

is not performed.

3. Remove the flapper screw (key 93), lockwasher

(key 84), and flapper (key 60). Invert the flapper so

that the flapper hook is on the opposite side of the

beam from the nozzle (key 58), and secure with the

lockwasher and screw.

4. Perform the calibration procedure and any other

necessary part of the calibration sequence.

Disassembling Relay

Disassembly can be accomplished in the following

steps. Key numbers are shown in figure 17.

1. Remove the relay according to the Changing Relay

section.

2. Remove the orifice assembly (key 88) and check

for orifice plugging or damage. Replace the O-ring

(key 90) before installing the orifice assembly.

3. Remove the casing screws (key 96) and washers

(key 98), casing assembly (key 85), and top dia-

phragm (key 91). On a high-temperature relay also

remove the top gasket (key 100) that covers the top

diaphragm.

4. Remove the spacer ring (key 84), diaphragm as-

sembly (key 86), and relay spring (key 92) from the

relay body (key 83). On a high-temperature relay also

remove the bottom gasket (key 99) from underneath

the diaphragm assembly.

5. Remove the screws (key 97), spring plate (key 95),

spring plate gasket (key 94), spring (key 93), and

valve plug (key 87).

6. Inspect the diaphragms and gaskets and replace if

necessary. Also replace the spring and valve plug if

they show signs of corrosion. The lower diaphragm

comes as part of an assembly and must be installed

as such. Clean all parts thoroughly before assembling.

7. Put the valve plug and its spring in the relay body.

Replace the spring plate gasket and spring plate and

secure with four screws.

8. Place the relay spring in the relay body and, on a

high-temperature relay, install a bottom gasket. Install

the diaphragm assembly, spacer ring, and top dia-

phragm on the body so that all flow passage holes are

lined up. On a high-temperature relay also install a

gasket over the top diaphragm.

9. Put the casing assembly on the top diaphragm so

that the lugs on the casing and spacer ring line up and

are also lined up with the body lug.

10. Install the casing screws and tighten them slowly

to ensure a good seal.

11. Install the assembled orifice assembly, and install

the relay according to the Changing Relay section.

Parts Ordering

Whenever corresponding with the Fisher Controls

sales office or sales representative about this equip-

ment, always mention the controller type number and

the serial number found on the unit nameplate (figure

11). When ordering replacement parts, also state the

complete 11-character part number of each required

part as found in the following parts list.

Parts Kits

Key Description Part Number

Controller Parts Kit

Contains keys 12, 15, 21, 24, 38, 55, 57, 58, 60, 62, 63, 64,

77, 79, 84, 86, 87, 93, 101, and 187

Standard Temperature

R2502 X0L52

High Temperature

R2502 X0H52

Relay Parts Kit

Contains keys 22, 85, 86, 87, 88, 90, 91, 92, 93 and 94,

(99 and 100 high temp only)

Standard Temperature RRELAY X0L12

High Temperature

RRELAY X0H12

Relay Replacement Kit

Contains keys 22, 43, and the relay assembly

Standard Temperature RRELAY X0L22

High Temperature

RRELAY X0H22

Heat Insulator Parts Kit

Contains keys 35, 36, 37, 38, 39, 40, and 53

R2500XH 0012

Parts

List

Heat Insulator (figure 14)

35 Heat Insulator Assembly, stainless steel 22A0033 X012

36 Shaft Coupling, stainless steel

1A5779 35032

37 Shaft Extension, K-Monel

1B6815 40022

38 Set Screw, stainless steel (2 req’d) 1E6234 X0022

39 Cap Screw, steel, pl (4 req’d)

1A3816 24052

40 Cap Screw, steel, pl (4 req’d)

1V2395 28982

53 Washer, carbon steel, pl (4 req’d)

1B8659 28982

Controller Common Parts (figure 16)

1 Pilot Case Back, zinc

Types 2502 and 2502C

1J4157 44012

Type 2502F 23A2073 X012

2 Pilot Case Cover, aluminum 50B9454 X012

3 Door Handle, steel, pl

1C8972 25082

4 Door Handle Shaft (not shown),

stainless steel

1C8984 14012

5 Machine Screw, stainless steel

1C8958 X0022

6 Washer Spring, stainless steel

1C8970 36032

7 Door Hook, steel, pl

1C8971 25082

8 Elastic Stop Nut, steel, pl

1C8959 X0012

9 Drive Pin, (2 req’d)

1C8991 X0022

11 Relay Tubing

Copper 17A9100 X012

Stainless steel (2502 and 2502C only) 17A9100 X022

12* Ball Bearing Ass’y, brass, pl

1C8983 000A2

*Recommended spare part.

Loading...

Loading...