Type 4660

9

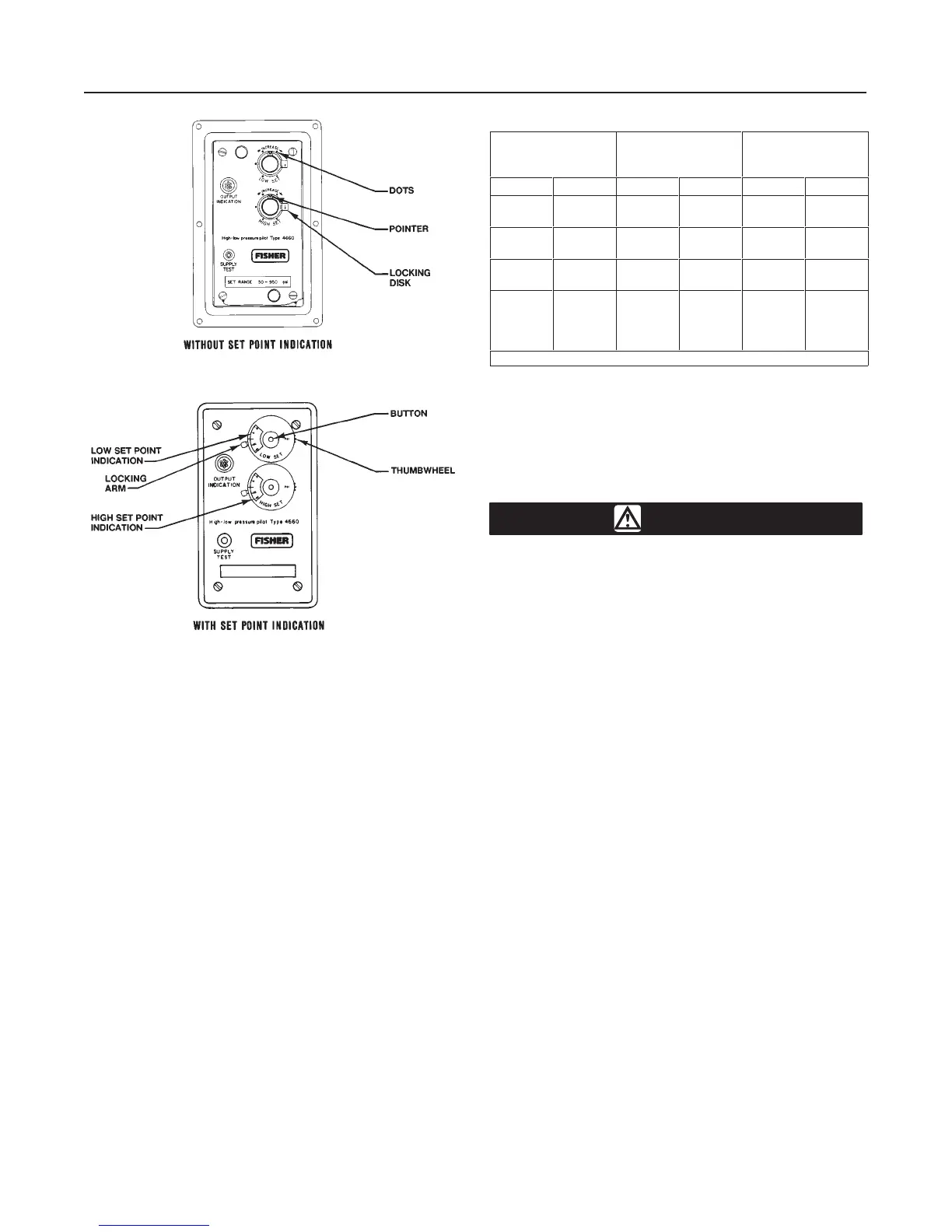

Figure 5. Set Point Adjustment Detail

48A3549-F

39A1578-A

A3300-1/IL

7. Turn the LOW SET knob clockwise until the low set

point pivot just comes in contact with the flapper, mov-

ing the nozzle beam off the nozzle. The pilot should

have zero output pressure (black indication on the op-

tional output indicator).

8. Refer to table 5 and turn the LOW SET knob clock-

wise to the desired set point value. For example, with

a 100 psig (690 kPa) Bourdon tube, turn the knob two

revolutions for a desired low set point of 24 psig (165

kPa).

9. Lock the locking disks (key 69).

Pilots With Optional Set Point Indication

Make sure each of the following five steps have been

performed completely before setting the high and/or

low set point pressures. Key numbers are shown in

figure 8.

1. Refer to the warning at the beginning of the Operat-

ing Information section. Be sure the Bourdon tube

contains no pressure.

2. Install either a pressure gauge or an optional output

indicator (key 88) in the output pressure line.

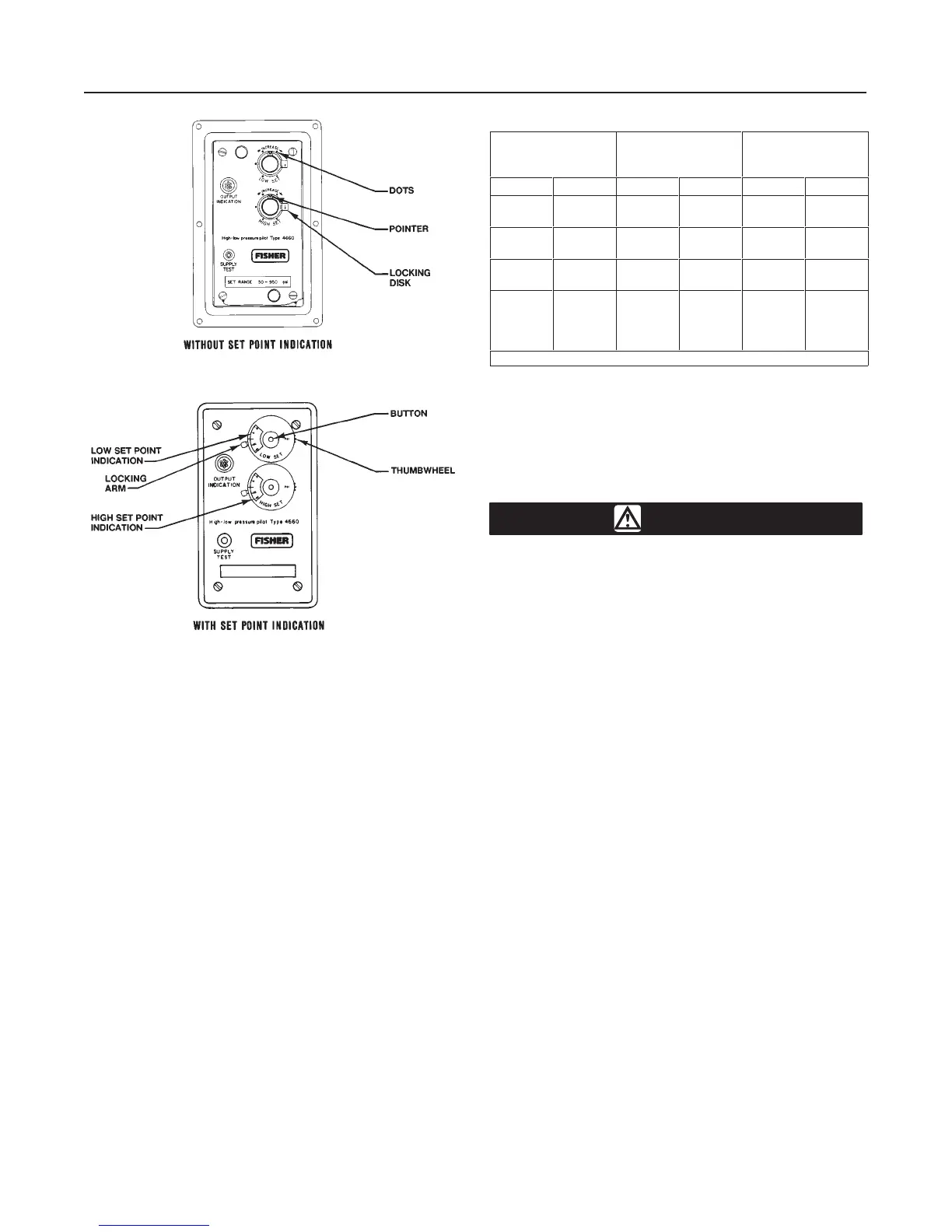

Table 5. Alternate Set Point Adjustment

BOURDON TUBE

RATING

PRESSURE

CHANGE

PER DOT

(1)

PRESSURE

CHANGE PER

REVOLUTION

Psig bar Psig bar Psig bar

50

100

3.4

6.9

1

2

0.1

0.1

6

12

0.4

0.8

250

500

17.2

34.5

5

10

0.4

0.7

30

60

2.1

4.1

1000

1500

69.0

103.4

20

30

1.4

2.1

120

180

8.3

12.4

2500

5000

7500

10,000

172.4

344.8

517.2

689.5

50

100

150

200

3.4

6.9

10.3

13.8

300

600

900

1200

20.7

41.4

62.1

82.7

1. Six dots per revolution.

3. Remove the cover screws (key 6) and the cover

(key 4).

4. Turn on the supply pressure. To check that the sup-

ply pressure is turned on, press the SUPPLY TEST

button located in the cleanout assembly (key 54) until

a flow sound is heard.

WARNING

To avoid personal injury or property

damage caused by a sudden release of

pressure, do not exceed the process

pressure values in table 4.

5. Connect an external pressure source to the process

pressure connection. This external pressure source

should be a regulated air or gas supply that is adjust-

able to zero. The external pressure source must be

capable of supplying a process pressure that will be

equal to or greater than the desired high set point

pressure.

6. Continue with the appropriate procedures described

below. Replace the cover and cover screws after all

adjustments are completed.

Setting the High and/or Low Set Point(s)

1. Adjust the external process pressure source to the

desired high or low set point. For example, if the pilot

is to trip at 50 psig (3.4 bar), apply 50 psig (3.4 bar) to

the pilot. Use a pressure gauge to measure the pro-

cess pressure.

2. Rotate the locking arm clockwise to unlock the mod-

ule. Slowly turn the HIGH SET or LOW SET knob until

the pilot trips.

3. Push the small button in the center of the knob with

a ball point pen or pencil and rotate the scale with the

thumbwheel on the right hand edge of the module (see

figure 5) until the number 50 aligns with the mark on

the left-hand edge of the module window.

4. Rotate the locking arm counterclockwise to lock the

module.

Loading...

Loading...