Type 667 Size 30-76 & 87

8

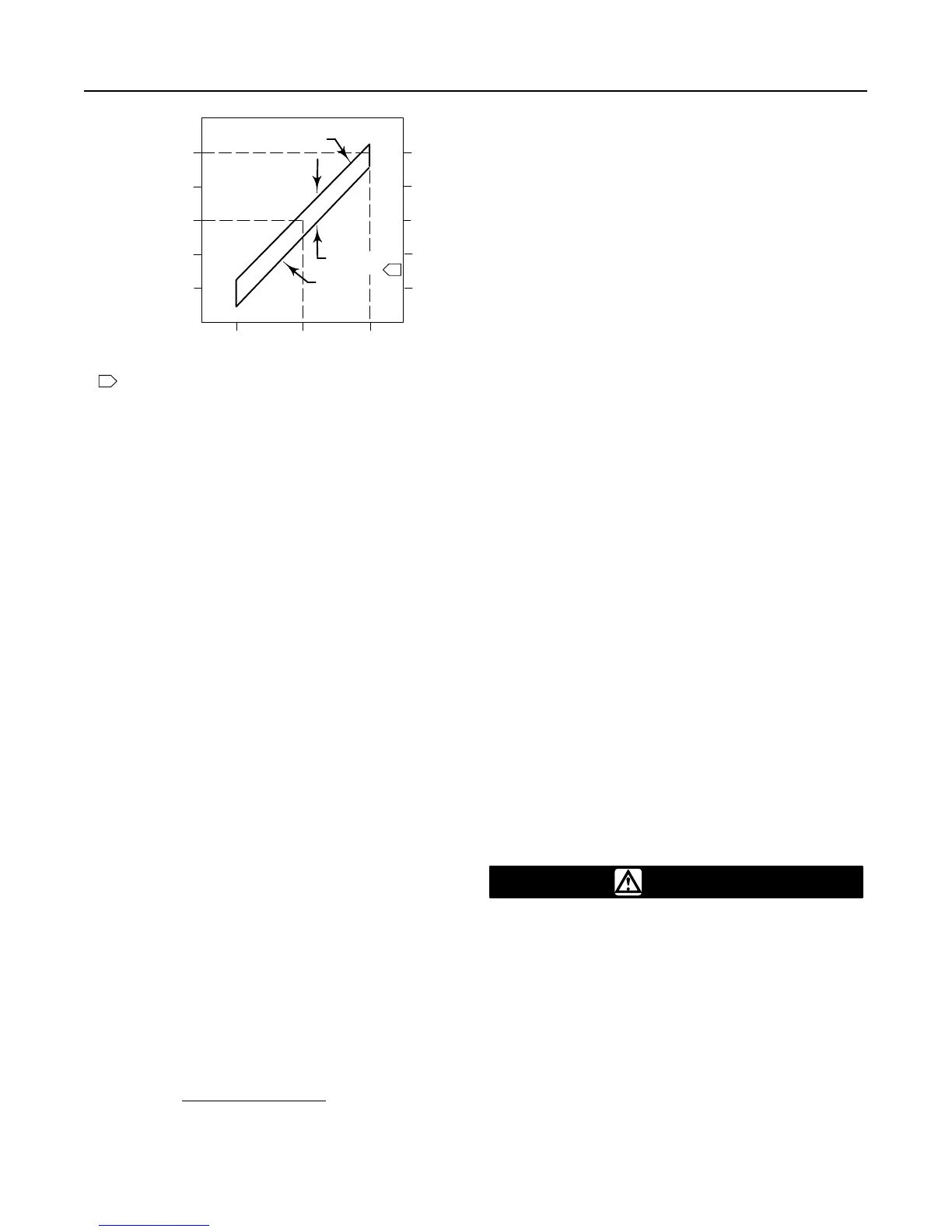

Figure 5. Typical Reverse-Acting Valve Response

to Deadband

UPPER

BENCH SET

PRESSURE

LOWER

BENCH SET

PRESSURE

9

3

0

OPENING

VALVE

15

1.0

0.6

0.2

CLOSING

VALVE

CLOSED

OPEN

MID RANGE

VALVE TRAVEL

DIAPHRAGM PRESSURE, PSIG

DIAPHRAGM PRESSURE, BAR

1

NOTE:

DEADBAND IS CAUSED BY FRICTION.

A6588-1 / IL

RANGE OF

DEADBAND

1

Deadband Measurement

Deadband is caused by packing friction, unbalanced

forces, and other factors in the control valve assembly.

Deadband is the range a measured signal can vary

without initiating a response from the actuator (see

figure 5). Each actuator spring has a fixed spring rate

(force). You have verified that the right spring was

installed in the actuator by completing the Bench Set

Spring Adjustment steps.

Deadband is one factor that affects the control valve

assembly operation during automatic loop control. The

control loop tolerance for deadband varies widely de-

pending on the loop response. Some common symp-

toms of the deadband being too wide are no move-

ment, a ‘‘jump” movement, or oscillating movements of

the actuator during automatic loop control. The follow-

ing steps are provided to determine the span of dead-

band. The percent of deadband is helpful in trouble-

shooting problems with the process control loop.

1. Start at a pressure near the lower bench set pres-

sure, slowly increase pressure until the valve is

approximately at mid-travel. Note this pressure read-

ing.

2. Slowly decrease pressure until movement of the

valve stem is detected, and note this pressure.

3. The difference between these two pressures is

deadband, in psi.

4. Calculate the percent of deadband by:

Deadband, psi

Deadband = Deadband, psi

= nn %

Bench Set Span, psi

Loading Connection

Key number locations are shown in figures 6, 7, and 8,

unless otherwise noted.

The loading pressure connections are made at the fac-

tory if the valve, actuator, and positioner come as a

unit. Keep the length of tubing or piping as short as

possible to avoid transmission lag in the control signal.

If a volume booster, valve positioner or other accesso-

ry is used, be sure that it is properly connected to the

actuator. Refer to the positioner instruction manual or

other manuals as necessary. For actuators shipped

separately or whenever the actuator pressure connec-

tions are installed, use the following steps:

1. Connect the loading pressure piping to the NPT

female connection in the side of the yoke (key 73).

2. For size 70 and 87 actuators, if necessary, remove

the 1/4-inch NPT bushing if a 1/2-inch NPT female

connection is needed to increase connection size. The

connection can be made with either piping or tubing.

3. Cycle the actuator several times to be sure that the

valve stem travel is correct when the correct pressure

ranges are applied to the diaphragm.

4. If valve stem travel appears to be incorrect, refer to

the Bench Set Spring Adjustment procedures at the

beginning of this section. Do not place the valve in ser-

vice if it is not reacting correctly to diaphragm loading

pressure changes.

Maintenance

Actuator parts are subject to normal wear and must be

inspected and replaced when necessary. The frequen-

cy of inspection and replacement depends on the se-

verity of service conditions. Because of the care Fisher

Controls takes in meeting all manufacturing require-

ments (heat treating, dimensional tolerances, etc.),

use only replacement parts manufactured or furnished

by Fisher Controls.

WARNING

Avoid personal injury or property dam-

age from sudden release of process

pressure or uncontrolled movement of

parts. Before performing any mainte-

nance operations:

D Always wear protective gloves,

clothing, and eyewear when performing

any maintenance operations to avoid

personal injury.

D Disconnect any operating lines pro-

viding air pressure, electric power, or a

Loading...

Loading...