Instruction Manual

D103626X012

685 Piston Actuator

June 2017

7

connector slightly, tightening the locknuts together, and (with the valve plug off the seat) screwing the stem either

into or out of the stem connector by means of a wrench on the locknuts.

7. If the total travel is adequate, tighten the stem connector (key 18) securely, lock the stem locknuts (if present)

against the connector, and adjust the indicator scale (key 22) on the yoke (key 21) to show valve plug position.

8. Provide a gauge, if necessary, to measure the pressure to the actuator. Make a final adjustment on the positioner to

set the starting point of valve travel and to obtain full travel for the given instrument range.

Handwheel Operation

If manual operation is required, the actuator should be equipped with a manual handwheel.

CAUTION

To avoid damage to actuator parts and difficult operation of actuator handwheels, open the bypass valve (key 66) before

using a handwheel.

The bypass assembly is furnished only when a handwheel actuator is specified. The bypass allows the pressure to

equalize on either side of the piston, so that the manual actuator can be used to position the control valve. Flow

through the bypass tubing is controlled by an angle needle valve, which is operated manually. This valve should be

closed when air pressure is being used to operate the actuator.

Key numbers referenced in the following steps are shown in figures 2 and 3. Refer to table 7 for handwheel

specifications.

1. Open the bypass valve.

2. Rotate the handwheel (key 45) to position the override engage pin (key 38) with the hole in the stem connector

(key 18). Use the engage pin control knob (key 33) to insert the override engage pin into the stem connector until it

stops. Refer to figure 2 for engage pin control knob operation.

Note

Depending on construction , the handwheel may have operation information stamped into the part. Always refer to steps 3 and 4

for operation information specific to push-down-to-close and push-down-to-open valves.

3. For a pushdowntoclose valve: Rotate the handwheel (key 45) clockwise to close the valve and counterclockwise

to open the valve.

4. For a pushdowntoopen valve: Rotate the handwheel (key 45) counterclockwise to close the valve and clockwise

to open the valve.

5. To disengage the manual handwheel, rotate the handwheel (key 45) to relieve any load placed on the override

engage pin (key 38), and use the engage pin control knob (key 33) to remove the override engage pin from the

stem connector (key 18). Refer to figure 2 for engage pin control knob operation.

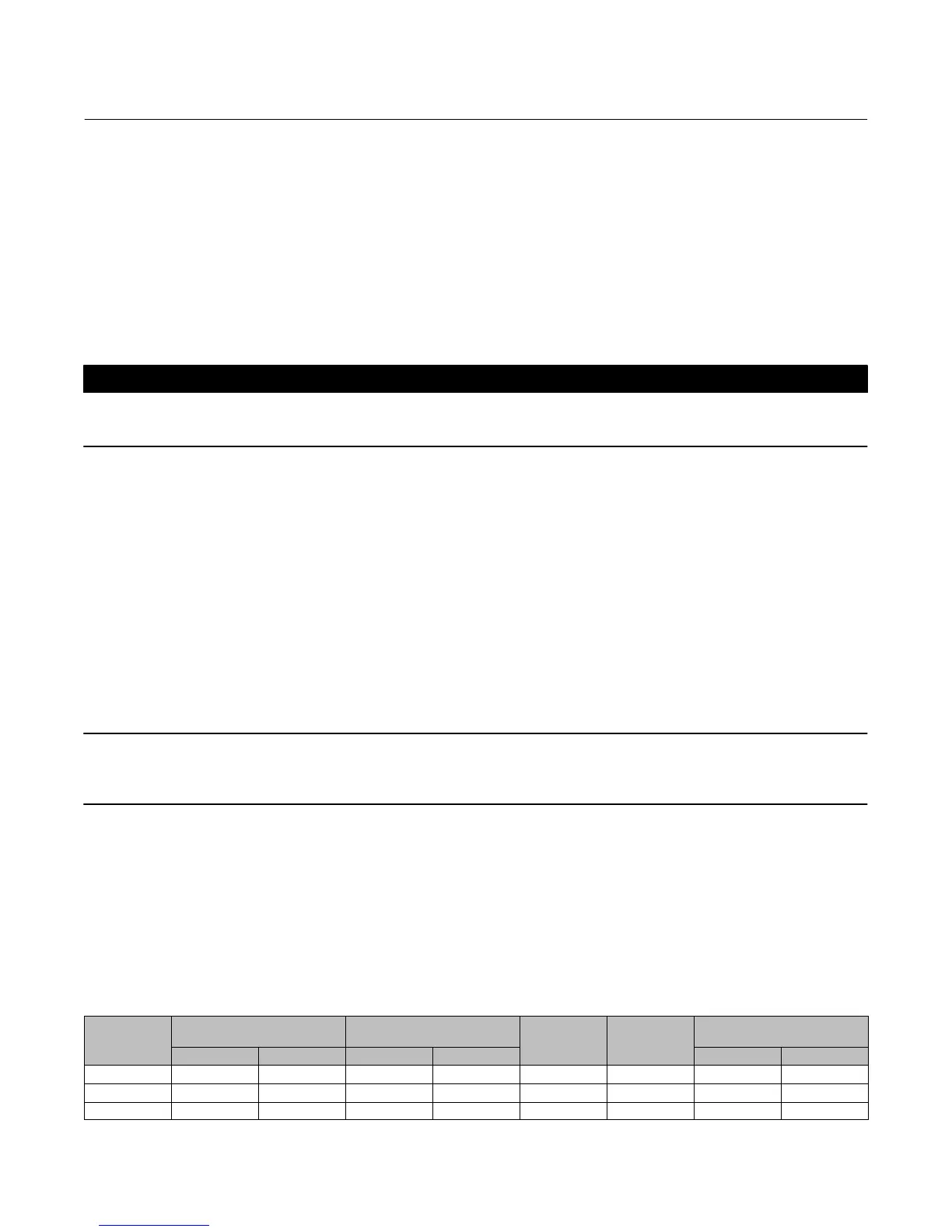

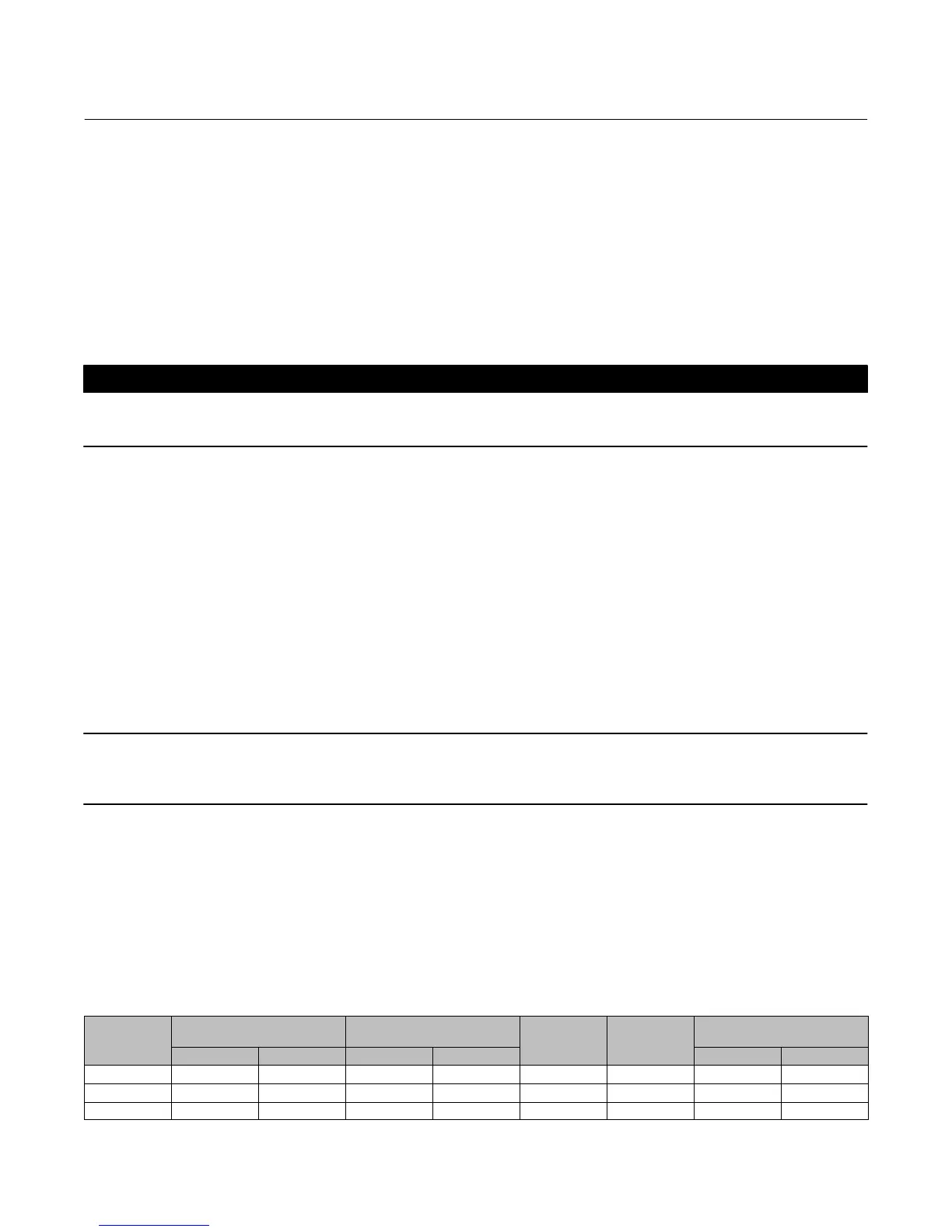

Table 7. Handwheel Specifications

ACTUATOR SIZE

OUTPUT THRUST HANDWHEEL DIAMETER

TURNS PER mm

OF TRAVEL

TURNS PER

INCH OF

TRAVEL

MAXIMUM RIM FORCE

REQUIRED

N lbs mm Inch N lbs

12 44482 10000 305 12 3.8 96 290 65

14 to 18 88964 20000 406 16 3.0 80 380 85

20 to 26 133447 30000 610 24 2.8 72 450 100

Loading...

Loading...