Type 9500

3

age before placing the valve in service. If the valve

and actuator are being re-installed, after removal, or if

you suspect that the linkage is out of adjustment, refer

to the

Linkage

portion of the

Adjustments

section be-

fore installing the valve in the pipeline. If the valve has

been purchased separately, or if the actuator has been

removed, complete the procedures in the

Actuator

Mounting

section of this manual before proceeding.

WARNING

Avoid personal injury from sudden re-

lease of process pressure. Before per-

forming any maintenance operations:

D Disconnect any operating lines pro-

viding air pressure, electric power, or a

control signal to the actuator. Be sure

the actuator cannot suddenly open or

close the valve.

D Use bypass valves or completely

shut off the process to isolate the valve

from process pressure. Relieve process

pressure on both sides of the valve.

Drain the process media from both

sides of the valve.

D Vent the power actuator loading

pressure and relieve any actuator spring

precompression.

D Use lock-out procedures to be sure

that the above measures stay in effect

while you work on the equipment.

1. Isolate the control valve from the line pressure, re-

lease pressure from both sides of the valve body, and

drain the process media from both sides of the valve.

If continuous operation is required during inspection or

maintenance, install a three-valve bypass around the

control valve assembly.

2. Be certain the pipeline flanges are in line with each

other and supported.

3. Inspect the valve body to be sure it is free of for-

eign material. Make sure the adjacent piping is free of

pipe scale, welding slag, and any other material that

could damage valve seating surfaces.

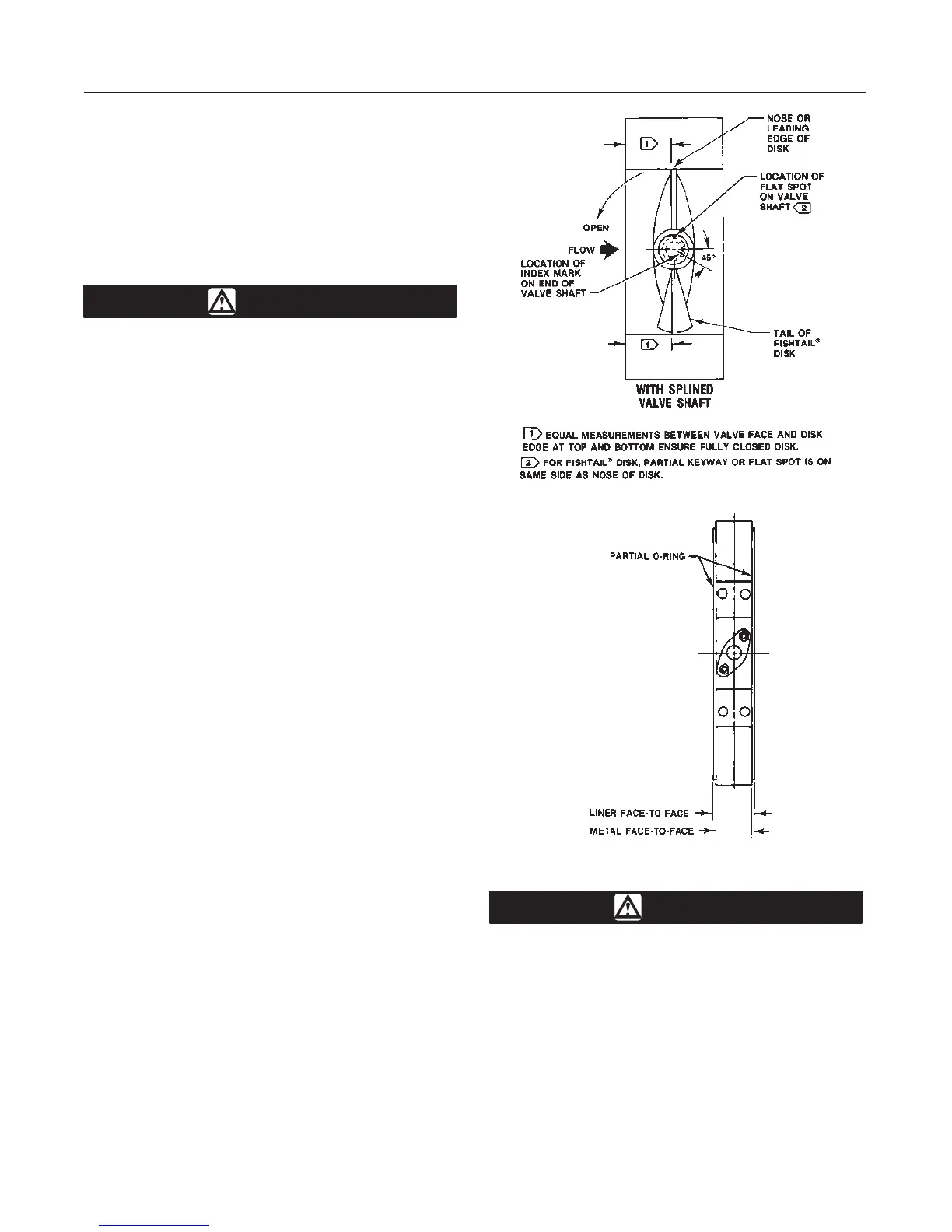

4. Measure to be sure the distance between the pipe-

line flanges is approximately 1/4 inch greater than the

valve face-to-face dimension. This will ensure easy

installation without distorting the liner (figure 3).

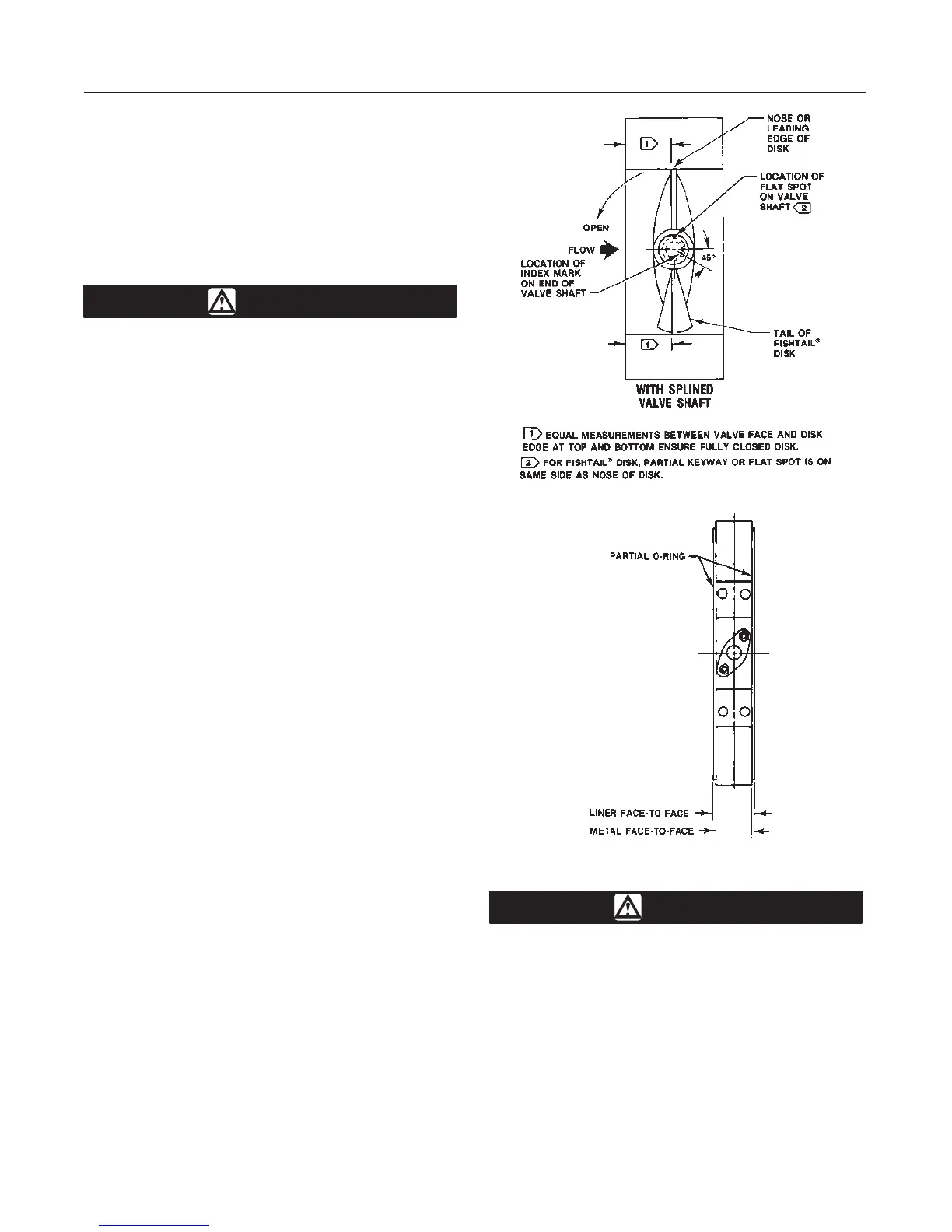

5. For conventional disks, flow may be in either direc-

tion; for Fishtail disks, flow must be such that the tail

of the disk (as shown in figure 2) will rotate into the

downstream side of the valve.

Figure 2. Valve Shaft Marking

A2755-1/IL

Figure 3. Partial O-Ring Location

A6017/IL

CAUTION

To avoid damaging valve parts, observe

the following precautions before insert-

ing the valve in the line.

a. The inside diameter of the mating piping or

flanges must be large enough to allow the valve

disk to rotate freely into the upstream and down-

stream piping, or the disk could be damaged.

b. The inside of the mating flange must also be

small enough to be in full contact with the partial

Loading...

Loading...