ES Valve

Instruction Manual

December 2008

8

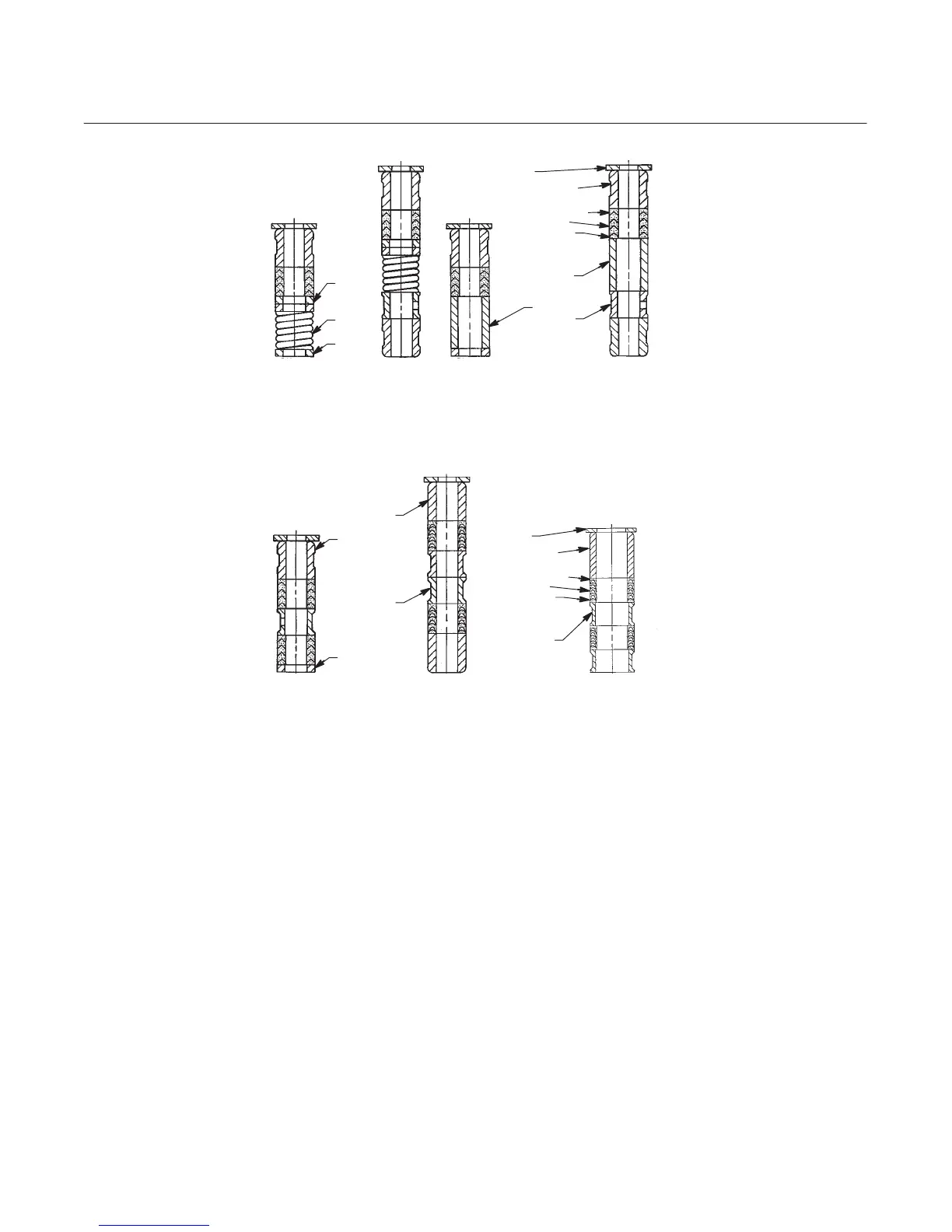

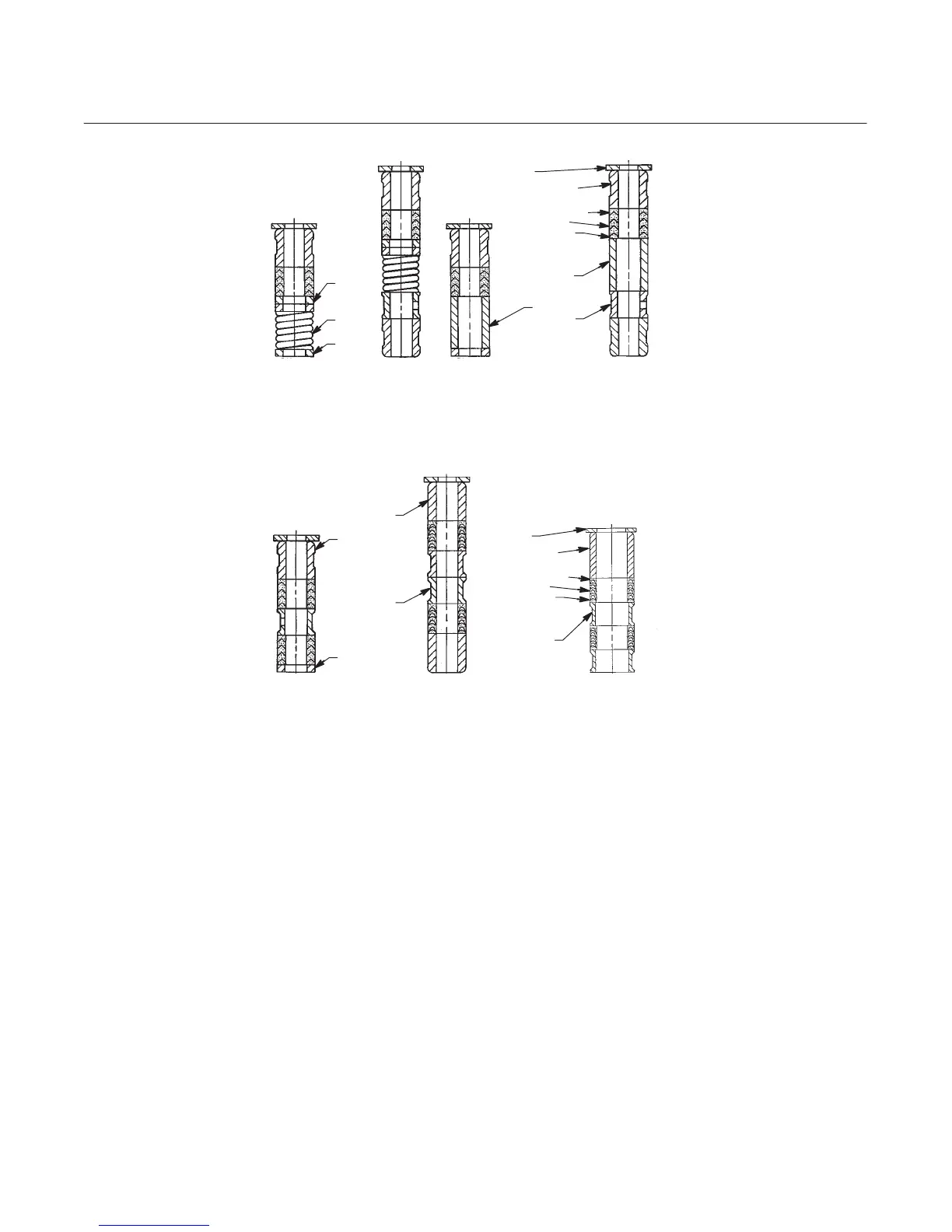

Figure 4. PTFE Packing Arrangements for Use in ENVIRO-SEALr Bellows Seal Bonnets

UPPER WIPER

(KEY 12)

PACKING SET: (KEY 6)

FEMALE ADAPTOR

PACKING RING

MALE ADAPTOR

BUSHING (KEY 13)

9.5 mm

(3/8 INCH)

STEM

12.7 mm

(1/2 INCH)

STEM

DOUBLE ARRANGEMENTS

9.5 mm

(3/8 INCH)

STEM

9.5 mm

(3/8 INCH)

STEM

12.7 mm

(1/2 INCH)

STEM FOR

NPS 2 VALVES

12.7 mm

(1/2 INCH)

STEM FOR

NPS 3 AND 4

VALVES

THRUST

RING

(KEY 39)

SPRING

(KEY 8)

THRUST

RING

(KEY 39)

THRUST

RING

(KEY 39)

BUSHING

(KEY 13)

BUSHING

(KEY 13)

SPACER

(KEY 8)

SPACER

(KEY 8)

SPACER

(KEY 8)

12.7 mm

(1/2 INCH)

STEM

SINGLE ARRANGEMENTS

FOR S31600 (316 SST)

PACKING BOX PARTS

FOR ALL PACKING BOX

MATERIALS EXCEPT S31600

UPPER WIPER

(KEY 12)

PACKING SET: (KEY 6)

FEMALE ADAPTOR

PACKING RING

MALE ADAPTOR

BUSHING (KEY 13)

SPACER

(KEY 8)

A5863-1 / IL

12B4183-A 18A0906-D 18A5338-A

12B4182-A SHT 1

12B4185-A SHT 1

12B4182-A SHT 2

12B4185-A SHT 2

11. Install bolting, using proper bolting procedures

during tightening so that the body-to-bonnet joint will

withstand test pressures and application service

conditions. The bolt torques in table 3 may be used

as guidelines.

12. Install new packing and the metal packing box

parts according to the appropriate arrangement in

figure 3, 5, or 6. For split ring packing, alternate the

positions of the splits to avoid creating a leak path.

Place a smooth-edged pipe over the valve stem and

gently tap each soft packing part into the packing

box, being sure that air is not trapped between

adjacent soft parts.

13. Slide the packing follower, upper wiper, and

packing flange (keys 13, 12, and 3, figure 8) into

position. Lubricate the packing flange studs (key 4,

figure 8) and the faces of the packing flange nuts

(key 5, figure 8). Install the packing flange nuts.

14. For spring-loaded PTFE V-ring packing,

tighten the packing flange nuts until the shoulder on

the packing follower (key 13, figure 8) contacts the

bonnet.

For ENVIRO-SEAL or HIGH-SEAL live-loaded

packing, refer to the note at the beginning of the

Maintenance section.

For graphite packing, tighten the packing flange nuts

to the maximum recommended torque shown in

table 4. Then, loosen the packing flange nuts, and

retighten them to the recommended minimum torque

shown in table 4.

For other packing types, tighten the packing flange

nuts alternately in small equal increments until one

Loading...

Loading...