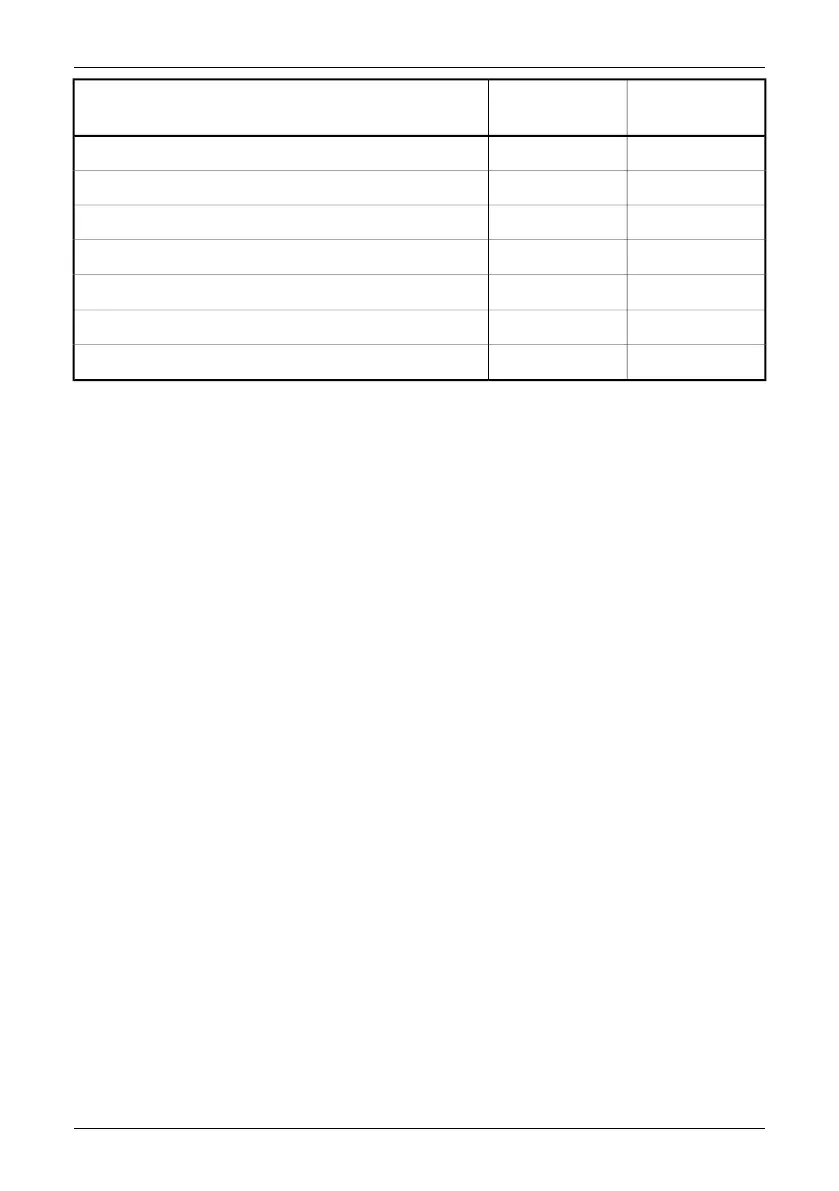

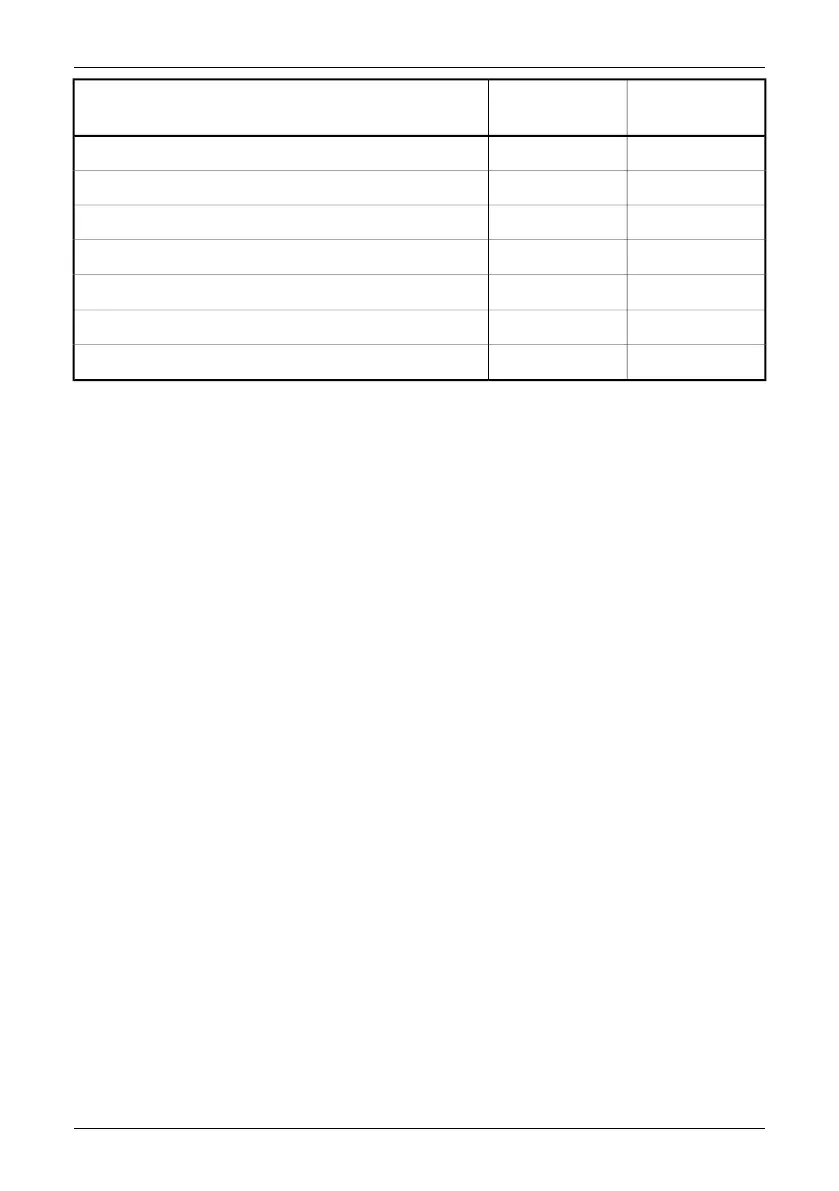

Failing areaGood areaExample for lightweight built-up cladding with defective

insulation

1.50.3Outside surface temperature in ℃

0.750.95Surface factor from IP17/01

0.92Critical external surface temperature factor, after IP17/01

5.180Insulation thickness to give this level of performance, mm

1.920.35Local U value W/m

2

K

0.78UKTA TN1 surface factor

0.93UKTA TN1 surface factor outside

Notes to the table

1 Values of surface resistances taken from ADL2 2001, are:

■ Inside surface 0.13 m

2

K/W

■ Outside surface 0.04 m

2

K/W

These originate from BS EN ISO 6946 (BN EN ISO 6946:1997 Building components

and building elements - Thermal resistance and thermal transmittance - Calculation

method).

2 Thermal insulation used here is assumed to have a conductivity of 0.03 W/m K.

3 The difference in temperature between an anomaly and the good areas is 1.2 de-

grees on the outside and 4.1 degrees on the inside.

4 The UKTA TN1 surface temperature factor for internal surveys is:

F

si

= (T

sia

– T

so

)/(T

si

– T

so

)

where:

T

sia

= internal surface temperature at anomaly

T

so

= external surface temperature (good area)

T

si

= internal surface temperature (good area)

5 The UKTA TN1 surface temperature factor for external surveys is:

F

so

= (T

soa

– T

si

)/(T

so

– T

si

)

where T

soa

= external surface temperature at anomaly

16.4.8.4.3 Selecting maximum acceptable defect area

The allowable area of defect is a quality control issue. It can be argued that there

should be no area on which condensation, mould growth or defective insulation will

occur and any such anomalies should be included in the report. However, a commonly

used value of 0.1% of the building exposed surface area is generally accepted as the

maximum combined defect area allowable to comply with the Building Regulations.

This represents one square metre in every thousand.

Publ. No. T559580 Rev. a486 – ENGLISH (EN) – November 17, 2010 87

16 – Introduction to building thermography

Loading...

Loading...