22

Chapter 3

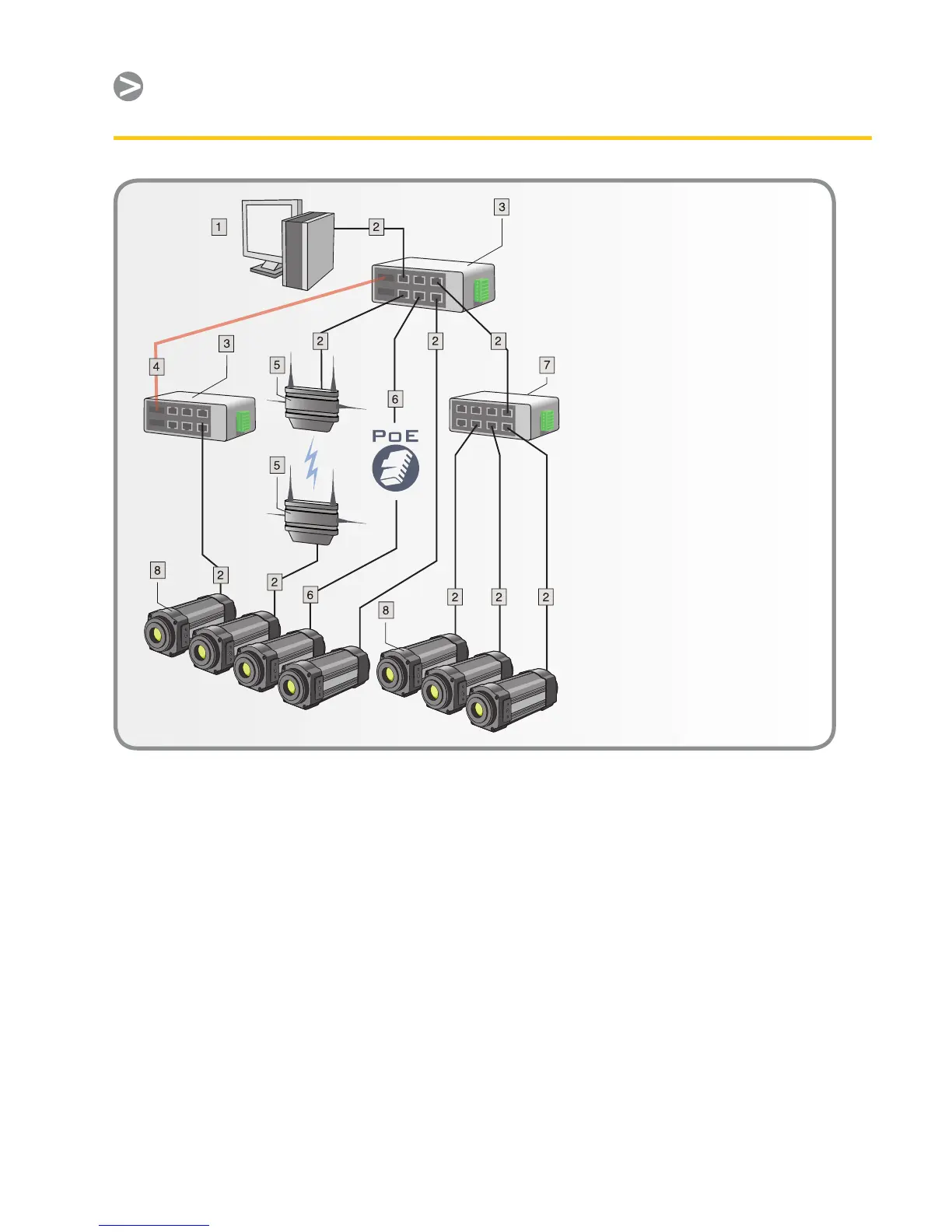

connected on the network for continuous

monitoring and data logging via PC or

PLC control. Typically, the telnet protocol,

accessed by the Windows

®

PC running

the application program, is used to query

the camera for data. This protocol is also

available for most PLCs. In either case, this

takes place though the camera’s Resource

Socket Services. (Command syntax is

contained in the camera’s ICD manual; a

few examples are listed in Appendix D.)

The system designer or FLIR would

create the message instructions that

allow the PLC to query the camera for

temperature data and thermographic

images in the same way it is done with PC

control. Alternatively, the PLC can hold

the Ethernet port open and call for the

camera to continuously output data to

this port at the maximum rate possible. In

either case, alarm functions and decision-

making is performed by the application

program running on the PLC (or PC if

applicable). (See Figure 6.) Typically,

temperatures and images collected for

trend analysis and statistical process

control purposes are stored on a separate

server connected to the network, which

is running transaction manager software

for downloading and storing data.

1 Computer, PLC, and/

or transaction manager

server

2 CAT-6 Ethernet cable

with RJ45 connectors

3 Industrial Ethernet

switches with ber optic

ports

4 Fiber optic cable

Wireless access points

6 CAT-6 Ethernet cable

with RJ45 connectors.

Powering the camera

using PoE (Power over

Ethernet)

7 Industrial Ethernet

switch

8 ThermoVision A320

cameras monitoring a

process or other target

objects

Figure 6. Generalized IR machine vision system and its communications network

Loading...

Loading...