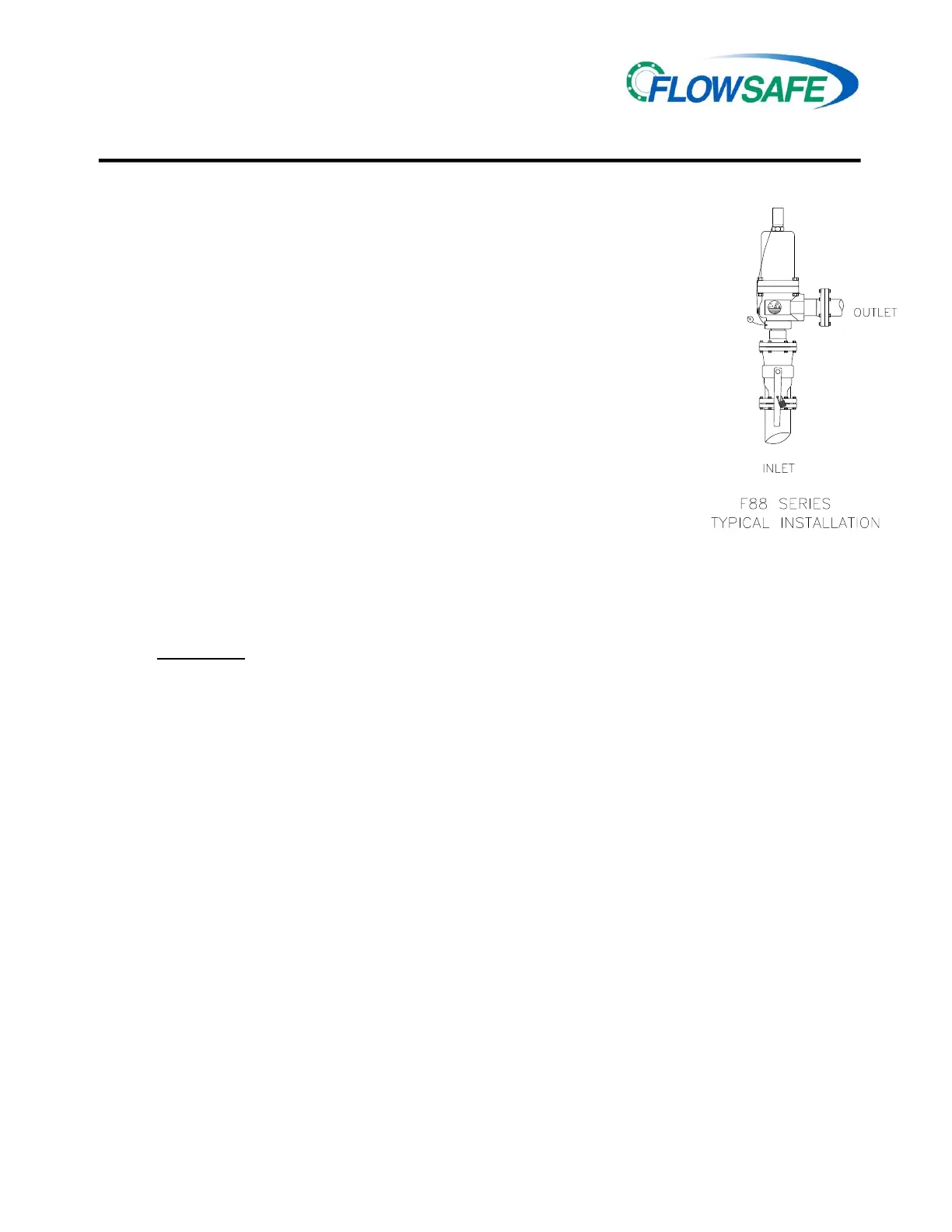

F88 Series valves are balanced against superimposed backpressure,

so that the set pressure will not change with backpressure.

Make sure that the inlet piping/flanges have an opening equal

to or greater than the valve's inlet diameter. Make sure that there

are no obstructions like gaskets, fittings, etc., in the flow path

to restrict the flow or cause chatter. Also, misaligned piping connections

may result in leaks or induce stresses in the valve assembly that interfere

with good operation. Discharge stacks exposed to the elements should

be configured so as to avoid the accumulation of snow and ice.

If a block valve is used below the relief valve, it should be opened before

pressurizing the system. This block valve should be locked open during

normal system operation.

Use only the wrench flats on the valve inlet bushing, taking care not to

make any wrench marks, for tightening and installation. Do not wrench

on the cast body or bonnet.

2.4 STARTUP

Foreign particles or dirt can damage the valve and make it inoperative. Prior to installation, clean out the

piping thoroughly. If the valve is not installed immediately, inlet and outlet connections should be

protected and covered.

Pressure can be applied to the valve as system pressure increases, or by opening the block valve (if

there is one) after the system has attained operating pressure. Verify the valve seat is leak-tight, in

accordance with Section 4.4.

The valve is now ready for service. Inspection and maintenance should be performed on a regular basis,

typically once a year, depending on the service conditions.

Loading...

Loading...