Do you have a question about the Flowserve Centrifugal Pump 8-UB-1 and is the answer not in the manual?

Covers general usage, disclaimers, copyright, and duty conditions.

Details safety symbols, personnel qualifications, ATEX, and hazard avoidance.

Summarizes important safety markings and their meanings.

Provides data on pump noise levels and related safety considerations.

Instructions for checking and handling equipment upon receipt.

Guidance on safe handling and lifting of the pump unit.

Advice on proper storage conditions to maintain pump integrity.

Procedures for environmentally responsible disposal.

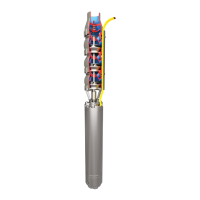

Describes the 8-UB-1 pump type and its applications.

Explains how pump size and serial numbers are identified.

Details the construction of key pump components.

Outlines the pump's performance characteristics and operational boundaries.

Specifies ideal placement for pump access, ventilation, and maintenance.

Provides instructions for creating a proper foundation for the pump unit.

Details the process and importance of grouting the baseplate.

Covers thermal expansion considerations for initial pump alignment.

Provides guidance on connecting suction and discharge pipework.

Procedure for verifying shaft alignment after piping connections.

Details requirements for safe electrical connections by qualified personnel.

Recommendations for protection systems against operational hazards.

Outlines initial checks and lubrication before start-up.

Lists recommended greases and lubrication schedules.

Instructions to ensure correct pump rotation direction.

Ensures protective guards are securely in place.

Steps for priming the pump and checking auxiliary systems.

Step-by-step guide for safely starting the pump.

Procedures for operating the pump under normal conditions.

Procedures for safely stopping and shutting down the pump.

Guidance on evaluating changes to pump duty parameters.

Outlines operator responsibilities for maintenance work.

Provides a recommended schedule for routine maintenance tasks.

Details on ordering replacement parts and information required.

Lists essential tools for pump maintenance.

Step-by-step guide for dismantling the pump.

Guidelines for inspecting dismantled pump components.

General guidance for reassembling the pump components.

Diagnosing and resolving pump overheating and seizure problems.

Troubleshooting bearing failure, pump vibration, and noise.

Addressing issues related to no liquid delivery, low pressure, or capacity.

Troubleshooting mechanical seal life, leaks, excessive power, and prime loss.

Diagnosing electrical issues like wrong rotation or slow motor speed.

Detailed sectional view of the pump with numbered parts.

Illustrates optional components like mechanical seals.

Provides a general overview drawing of the pump set.

Details contract-determined certificates like CE and ATEX marking.

References additional documents for drivers, controllers, and seals.

Lists external references for further technical reading.

| Brand | Flowserve |

|---|---|

| Model | Centrifugal Pump 8-UB-1 |

| Category | Water Pump |

| Language | English |