Do you have a question about the Flowserve CPX and is the answer not in the manual?

General information and guidance for product use and installation.

Details on regulatory compliance, CE marking, and product approvals.

Specifies product selection based on purchaser order and operating conditions.

Crucial section covering safety measures, hazards, and warnings.

Information for pump identification via nameplate and safety labels.

Guidance on obtaining and retaining specific machine performance data.

Information on noise exposure limits and typical sound pressure levels.

Procedures for checking equipment completeness and condition upon arrival.

Guidelines for safe handling of pump boxes, crates, and pallets.

Safety instructions for lifting pump sets and components using cranes.

Recommendations for storing the pump in a clean, dry location away from vibration.

Instructions for environmentally sound disposal of the product and its parts.

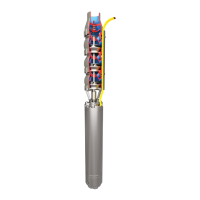

Overview of the modular centrifugal pump design for various liquid pumping needs.

Explanation of pump size designation and serial number on the nameplate.

Description of key components like pump casing, impeller, shaft, and bearings.

Information on product specifications, operating limits, and influencing factors.

Guidance on selecting an appropriate installation location for access and ventilation.

Installer's responsibility for alignment of loose coupling elements on baseplated sets.

Requirements and methods for installing pump units on foundations to prevent failure.

Procedures for grouting foundation bolts and baseplates for solid contact.

Steps and methods for ensuring proper pump and motor alignment.

Instructions for connecting suction, discharge, and auxiliary piping safely.

Final checks after piping connection to ensure no pipe strain.

Safety precautions and regulations for electrical hookups.

Recommended safety systems for hazardous areas or handling hazardous liquids.

Steps before initial startup, including lubrication checks.

Recommended oils and greases for pump lubrication.

Information on setting and adjusting impeller clearance.

Critical step to ensure correct motor rotation to prevent damage.

Importance of secure fitting and maintenance of protective guards.

Procedures for filling and priming the pump for operation.

Detailed steps for starting CPX/CPXR/CPXN and CPXP pumps.

Guidelines for operating the pump under normal conditions.

Procedures for safely stopping and shutting down the pump.

Factors influencing pump performance and operation.

Operator responsibility for ensuring maintenance is performed by qualified personnel.

Recommended schedule for routine inspections and maintenance tasks.

Information on ordering and storing replacement parts correctly.

List of common spare parts recommended for two years of operation.

List of typical tools required for pump maintenance.

Recommended torque values for fasteners during assembly and maintenance.

Procedure for adjusting impeller clearance after dismantling.

Steps and precautions for dismantling the pump for overhaul.

Guidelines for inspecting used parts before reassembly.

General instructions and methods for pump reassembly.

Details on various mechanical seal types and their dimensions.

Sectional drawings and parts lists for CPX and CPXN pump models.

Sectional drawing and parts list for the CPXR pump model.

Sectional drawings and parts lists for CPXP pump models.

Further details on bearing housing sealing and key drive impeller options.

Diagrams showing parts interchangeability across different pump models.

Information on obtaining specific general arrangement drawings.

Information on obtaining additional supplementary user instruction manuals.

Guidance on maintaining records of agreed product changes.

List of references and guides for further technical information.

| Brand | Flowserve |

|---|---|

| Model | CPX |

| Category | Water Pump |

| Language | English |

Loading...

Loading...