Do you have a question about the Flowserve 12M264 and is the answer not in the manual?

General guidance on keeping instructions with the product and product quality.

Requirements for CE marking directives applicable to machinery and equipment.

Information on reliability, accuracy, limitations, and reproduction rights of the instructions.

Product selection based on purchaser order specifications and suitability for application.

General safety instructions, warning symbols, and personnel qualifications.

Information on nameplates and various warning labels for safe operation.

Details on performance parameters and operating data for the pump.

Guidance on pump noise levels, measurement, and considerations for health and safety.

Procedures for checking equipment upon receipt and reporting any discrepancies or damage.

Guidelines for safely handling boxes, crates, pallets, and cartons for pumps.

Instructions for lifting pump sets using cranes and trained personnel.

Recommendations for short-term and long-term storage of pumps to prevent damage.

Procedures for environmentally acceptable recycling and disposal of the product and its parts.

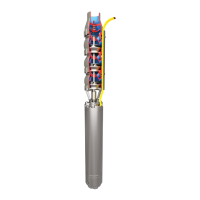

Description of M Slurry pumps, their standard features, and optional configurations.

Explanation of how pump names identify construction features and options.

Detailed description of the pump casing, impeller, shaft, and other key components.

Data on operating limits, speed-torque curves, and maximum working pressures.

Tables detailing engineering data, materials of construction, and dimensions.

Guidelines for selecting an appropriate location for pump installation, considering access and ventilation.

Information on motor supply and the installer's responsibility for assembly and alignment.

Requirements for pump and driver foundations, including size, mass, and foundation bolts.

Procedures for installing the baseplate, cleaning, initial levelling, and securing foundation bolts.

Procedures and importance of accurate shaft alignment for pump and driver.

Step-by-step guide for grouting the pump and baseplate to ensure rigid support.

Guidelines for suction, discharge, and auxiliary piping to minimize losses and ensure proper operation.

Final checks for shaft alignment after piping is connected, ensuring no pipe strain.

Safety requirements and considerations for electrical connections, including hazardous areas and EMC.

Determining and implementing correct lubrication methods for the pump set.

Recommended oil and grease lubricants for various pump frames and operating conditions.

Crucial step to ensure correct pump rotation direction before starting the motor.

Importance of ensuring protective guards are securely fitted around the pump.

Ensuring auxiliary systems are operational and the pump is properly primed before operation.

Step-by-step instructions for safely starting the pump, including checks and precautions.

Procedures for running the pump, including venting, gland adjustment, and mechanical seal checks.

Safe procedures for stopping and shutting down the pump, including draining for frost protection.

Factors affecting pump performance and how changes in duty affect operation.

Operator's responsibility for maintenance, safety, and personnel qualifications.

Recommended maintenance schedule, including checks for auxiliary systems, leaks, and bearing levels.

Information required for ordering spare parts and ensuring compatibility.

Lists of recommended spare parts and consumable items for start-up and extended operation.

List of typical tools required for pump maintenance and repair.

Table of recommended tightening torques for various bolt sizes and thread types.

Importance of maintaining impeller axial clearance for pump efficiency.

Step-by-step instructions for safely dismantling pump components.

Guidelines for inspecting parts after disassembly to ensure proper reassembly and operation.

Step-by-step instructions for assembling pump components.

Procedures for adjusting impeller axial clearance to ensure proper operation.

Table of probable causes and possible remedies for system-related pump faults.

Table of probable causes and remedies for mechanical faults in pump operation.

Troubleshooting common motor electrical problems affecting pump operation.

Illustrated parts list and diagram for Standard Duty pumps, Frames 1 & 2.

Illustrated parts list and diagram for Standard Duty pumps with Expeller, Frames 1 & 2.

Illustrated parts list and diagram for Standard Duty pumps, Frames 3 & 4.

Illustrated parts list and diagram for Standard Duty pumps with Expeller, Frames 3 & 4.

Illustrated parts list and diagram for Severe Duty pumps, Frames 2, 3 & 4.

Illustrated parts list and diagram for Severe Duty pumps with Expeller, Frames 3 & 4.

Illustrated parts list and diagram for Severe Duty pumps, Frames 5 & 6.

Illustrated parts list and diagram for Severe Duty pumps with Expeller, Frames 5 & 6.

Information on certificates provided for CE marking and ATEX compliance.

Details on supplementary instructions for pump sets, drivers, and control components.

Information on changes agreed with Flowserve Pump Division and their maintenance.

References to additional manuals, standards, and resources for further information.

| Brand | Flowserve |

|---|---|

| Model | 12M264 |

| Category | Water Pump |

| Language | English |