Do you have a question about the Flowserve VTP and is the answer not in the manual?

General safety guidelines and warnings for pump operation and maintenance.

Explains safety symbols, personnel qualifications, and safety actions.

Safety requirements for equipment operating in potentially explosive atmospheres.

Procedures for receiving, handling, and safely lifting pump components.

Guidelines for pump storage and environmental disposal at end of product life.

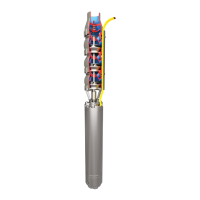

Describes pump types and explains the naming convention for components.

Details on drivers, discharge head assemblies, column assemblies, and bowl assemblies.

Guidelines for site selection, pre-installation checks, and foundation preparation.

Steps for lifting, assembling, and aligning pump and driver components.

Checks before commissioning and details on pump lubricants and their application.

How to adjust impellers and procedures for starting the pump safely.

Guidelines for operating the pump, shutting it down, and understanding performance duty.

Responsibilities, safety, and schedule for routine and periodic maintenance.

Maintenance of stuffing boxes, impeller adjustment, and ordering spare parts.

Torque values for fasteners and a list of required tools for maintenance.

Identifies common pump, motor, and electrical faults, their causes, and recommended solutions.

Illustrative cross-sections of Product Lubricated, Enclosed Tube, and Suction Barrel VTPs.

Information on certifications, supplementary instructions, and managing change records.

Cross-reference of part numbers across different nomenclature systems.

| Type | Vertical Turbine Pump |

|---|---|

| Application | Water supply, irrigation, industrial processes |

| Head | Up to 1, 000 ft (305 m) |

| Materials | Stainless steel, cast iron, bronze, other alloys |

| Flow Rate | Varies by model and configuration |

| Standards | ANSI |

Loading...

Loading...