FlowAct Diaphragm Linear Actuator FCD VLENIMFACTA4 10/16

16

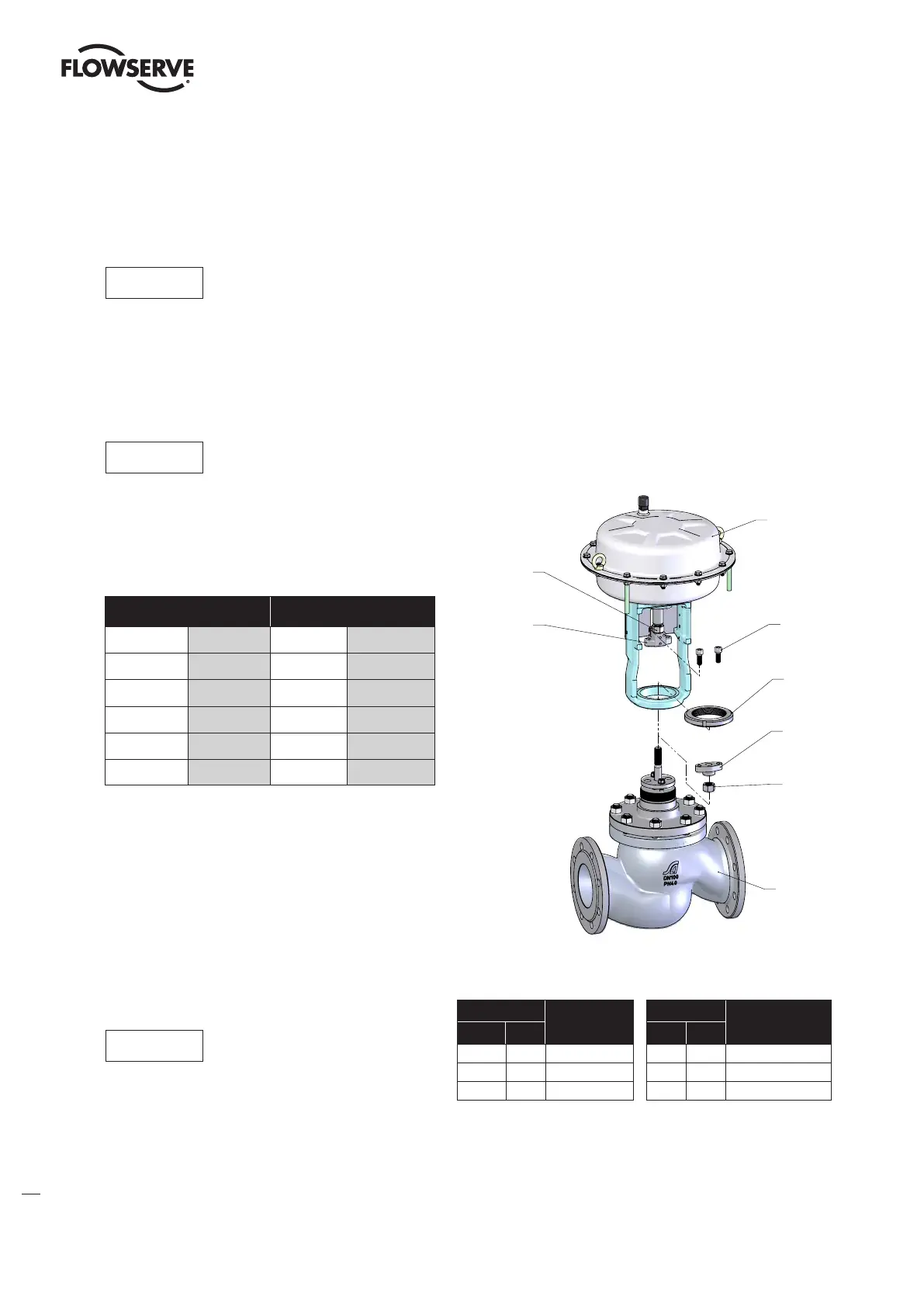

Reassemble the Actuator onto

the valve:

1. Mount the actuator onto the bonnet and tighten the

yoke lock nut (76) clockwise.

NOTICE

The legs of the yoke should be parallel

to the flow direction.

2. Move the actuator to the open position.

3. Screw in the lock nut (113) onto the valve stem so it

is screwed all the way and lower coupling (345) three

turns and move the actuator into the closed position.

NOTICE

The plug must be aligned onto the

seat. The cushioning effect of the bel-

lows can be prevented by tightening the packing follower.

4. Move the actuator back into the open position and

adjust the distance between the lower coupling (345)

and upper coupling (249) by adjusting the stroke length.

Valve size Stroke

15 - 25 1/2“ - 1“ 10

+ 0,5

mm 0.394

+ 0.02

in.

15 - 50 1/2“ - 2“ 20

+ 0,5

mm 0.787

+ 0.02

in.

65 - 100 3“ - 4“ 40

+ 0,5

mm 1.574

+ 0.02

in.

125 - 150 6“ 60

+ 0,8

mm 2.362

+ 0.03

in.

200 - 300

1)

8“ - 12“

1)

80

+ 0,8

mm 3.150

+ 0.03

in.

400 16“ 100

+ 0,8

mm 3.937

+ 0.03

in.

Table 11: Stroke adjustment length (

1)

depends on the valve

series)

5. Move the actuator to the close position and install the

cap screws (240).

6. Lock the lock nut (113). Keep upper coupling (249)

from turning by securing with a wrench.

7. If a handwheel-side was mounted reassemble as next

(see pages 37 - 38).

NOTICE

The handwheel-side always presses

on the coupling, depending on the

safety position when actuated. The lever arms must be

positioned so that this condition is given.

8. Place the handwheel-side on the yoke and straighten

it, mount the washer (140) and hex bolt (150) and

tighten it, if applicable.

9. Check handwheel-side for correct limit position, if

applicable.

10. Reassemble the accessory on the valve as necessary,

see relevant accessory User Instruction.

11. Perform three full strokes and check the free movement

of the actuator.

12. For installation the valve into the pipeline and further

steps see User Instructions for applicable valve types.

13. Log the maintenance interval and the work performed.

Actuator

240

76

345

113

Valve

249

344

Figure 9: Yoke assembly drawing

Item

Part

Item

Part

WW

EU

WW EU

76 5.10 Yoke lock nut 249 5.3 Upper coupling

113 5.2 Lock nut 344 5.4 Lock nut

240 5.5 Cap screw 345 5.1 Lower coupling

Table 12: Coupling parts identification

Loading...

Loading...