Limitorque Actuation Systems L120 Series FCD LMENIM1201-05-A4 – 03/18

10

4.2 Safety Practices

The following checks should be performed to maintain safe operation of the L120 actuator.

• Mount motors on a horizontal plane, if possible.

• Keep the controls compartment clean and dry.

• Keep the valve stem clean and lubricated.

• Set up periodic operating schedule for infrequently used valves.

• Carefully check for correct motor rotation direction. If the motor is driving the valve in the wrong

direction, interchange any two leads on three-phase motors or switch the armature leads on DC and

single-phase motors.

• Use a protective stem cover. Check valve stem travel and clearance before mounting covers on rising

stem valves.

• Verify all actuator wiring is in accordance with the applicable wiring diagram, national and local codes,

and Table 4.1.

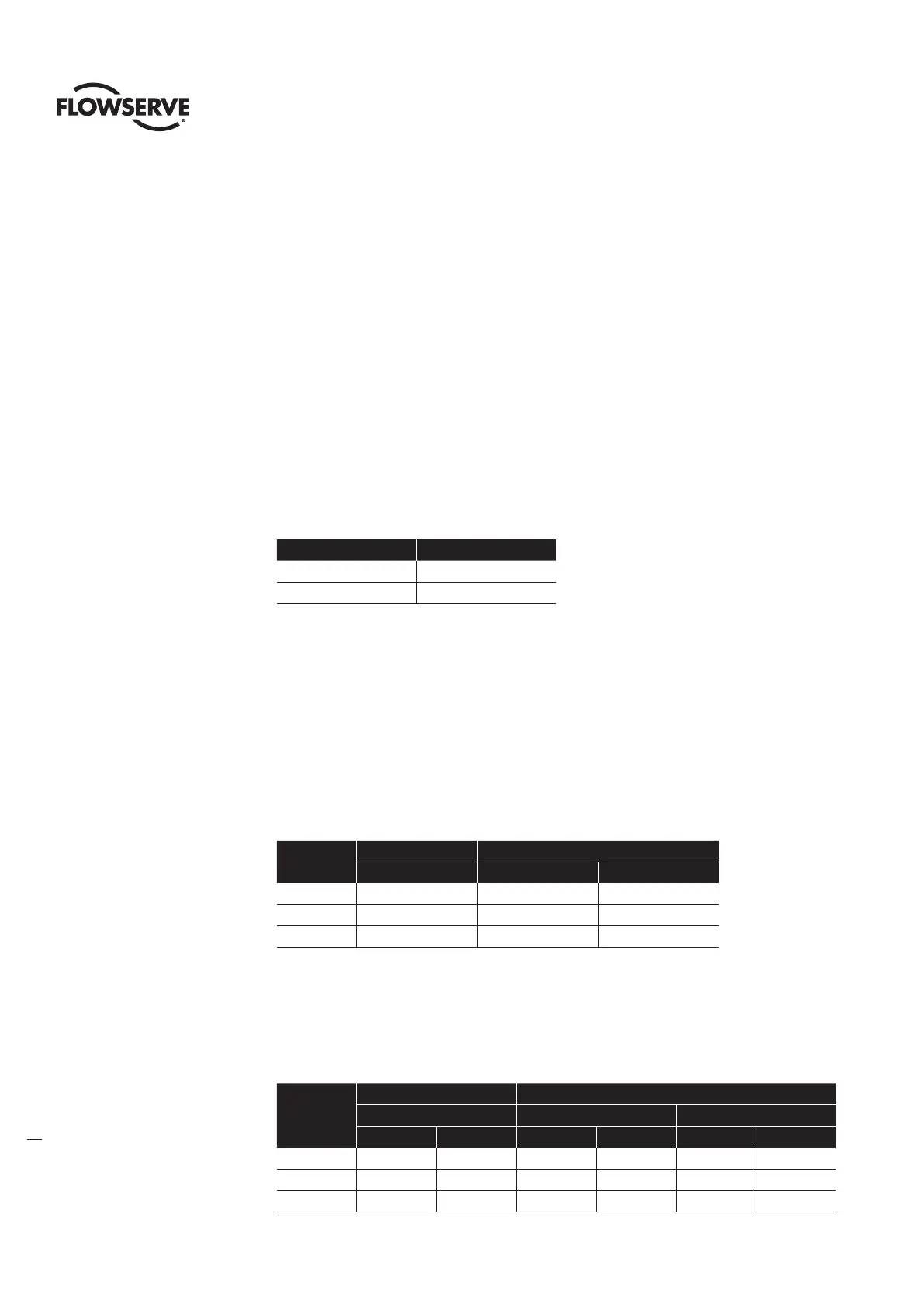

Table 4.1 – Required Rating for External Wiring

Up to: Use wire rated at least:

40°C 60°C

60°C 75°C

4.3 Initial Actuator Preparation

Replace all molded plastic conduit and top protectors (installed for shipping purposes only) with pipe

plugs when installation wiring is complete.

4.3.1 Mounting Base

The mounting hole sizes and quantities are as detailed in Table 4.2.

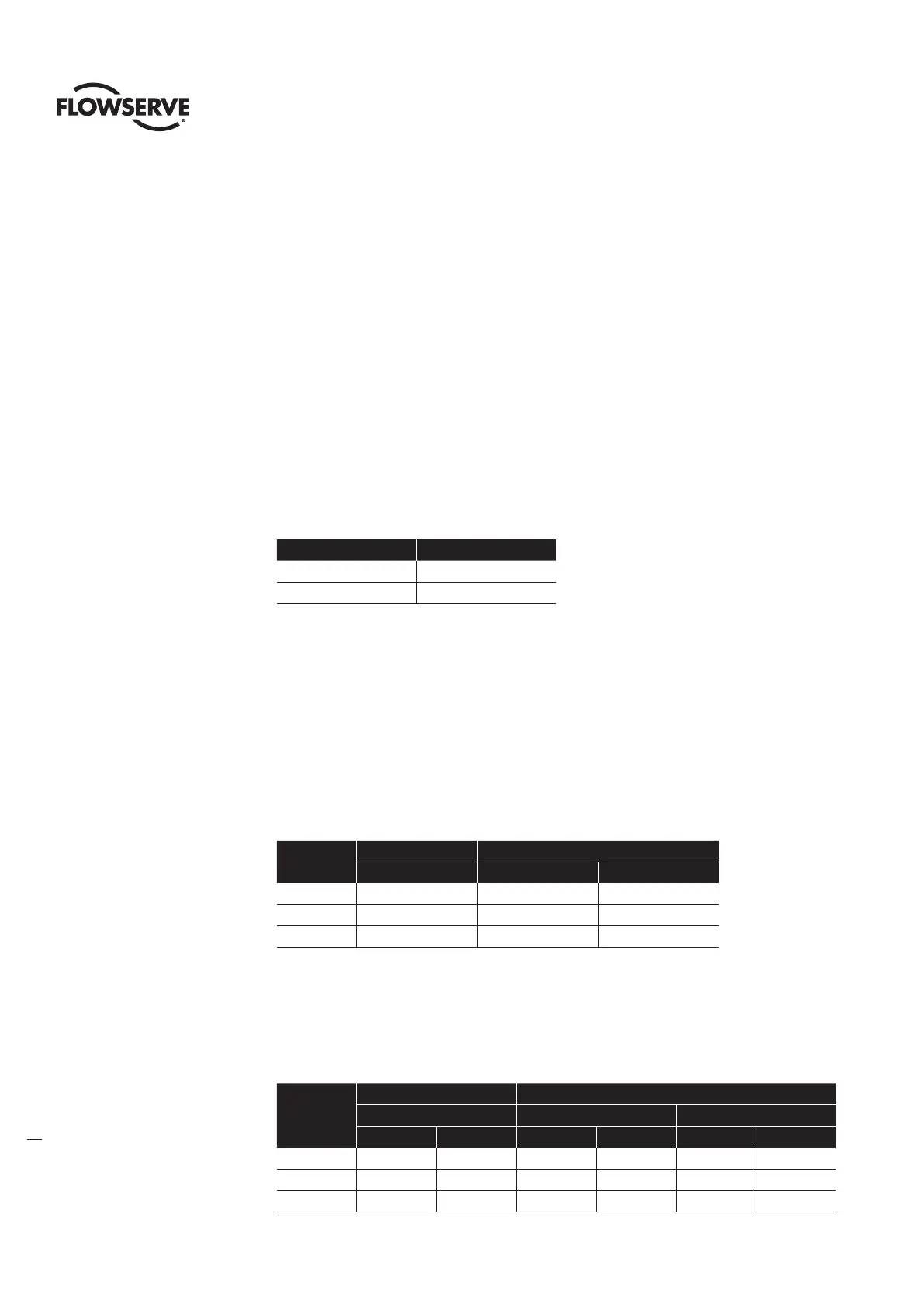

Table 4.2 – Mounting Base Dimensions

Actuator Size

Mounting Holes Tap size

Quantity MSS ISO

L120-10 4

3

⁄8-16x0.88 M10x1.5x22.4

L120-20 4

5

⁄8-11x1.25 M16x2x32

L120-40 4

5

⁄8-11x1.25 M16x2x32

4.3.2 Stem Acceptance

The maximum stem acceptance is provided in Table 4.3.

Table 4.3 – Maximum Stem Acceptance

Actuator size

Drive 2 Drive 1

Tapped Bore Key

inch mm inch mm inch mm

L120-10 1.25 32 1.00 25 ¼x3/32 8x6

L120-20 2.25 57 1.875 47 ½x3/16 14x9

L120-40 2.625 66 2.125 52 ½x3/16 16x10

Loading...

Loading...