51-18 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

* MPC (Minimum position cutoff)

Failure Probable Cause Corrective action

No LED is blinking 1. Current source below 3.6 mA

2. Incorrect wiring polarity

1. Verify current source is outputting at

least 3.6 mA

2. Check wiring for correct polarity

Erratic communications 1. Current source bandwidth not limited to

25Hz

2. Maximum cable length or cable

impedance exceeded

3. HART modem connected to PC RS-232

port not receiving enough power

4. Interference with I.S. barrier

5. Current source stripping (filtering) HART

signal.

1. Maximum allowable current source

rate of change is 924 mA per second

2. Check cable conductor size, length

and capacitance. Refer to 'Cable

Requirements' on page 11.

3. Verify laptop battery is not low

4. Must use HART compatible I.S.

barrier

5. Use the HART filter (VHF) available

from Flowserve

Unit does not respond

to analog commands

1. Unit is in digital command mode

2. Error occurred during calibration

1. Switch to analog command mode

with handheld communicator or Soft-

Tools.

2. Correct calibration error. Recalibrate

Valve position reading is

not what is expected

1. Stem position sensor mounting is off 180

degrees

2. Stroke not calibrated

3. Tight shutoff (M.P.C.)* is active

4. Custom characterization or soft stops

active

Position is driven fully

open or closed and will

not respond to com-

mand

1. Stroke not calibrated

2. Inner-loop hall sensor not connected

3. Wrong air action entered in software

4. Actuator tubing backward

5. Electro-pneumatic converter

malfunctioning

6. Control parameter inner-loop offset is too

high/low

1. Calibrate valve stroke

2. Verify hardware connections

3. Check ATO (Air-to-open) and ATC

(Air-to-Close) settings. Recalibrate

4. Verify ATO/ATC actuator tubing

5. Replace electro-pneumatic converter

6. Adjust inner-loop and see if proper

control resumes

Sticking or hunting oper-

ation of the positioner

1. Contamination of the electro-pneumatic

converter.

2. Control tuning parameters not correct

1. Check air supply for proper filtering

and meeting ISA specifications

ISA-7.0.01

2. Lower proportional gain settings

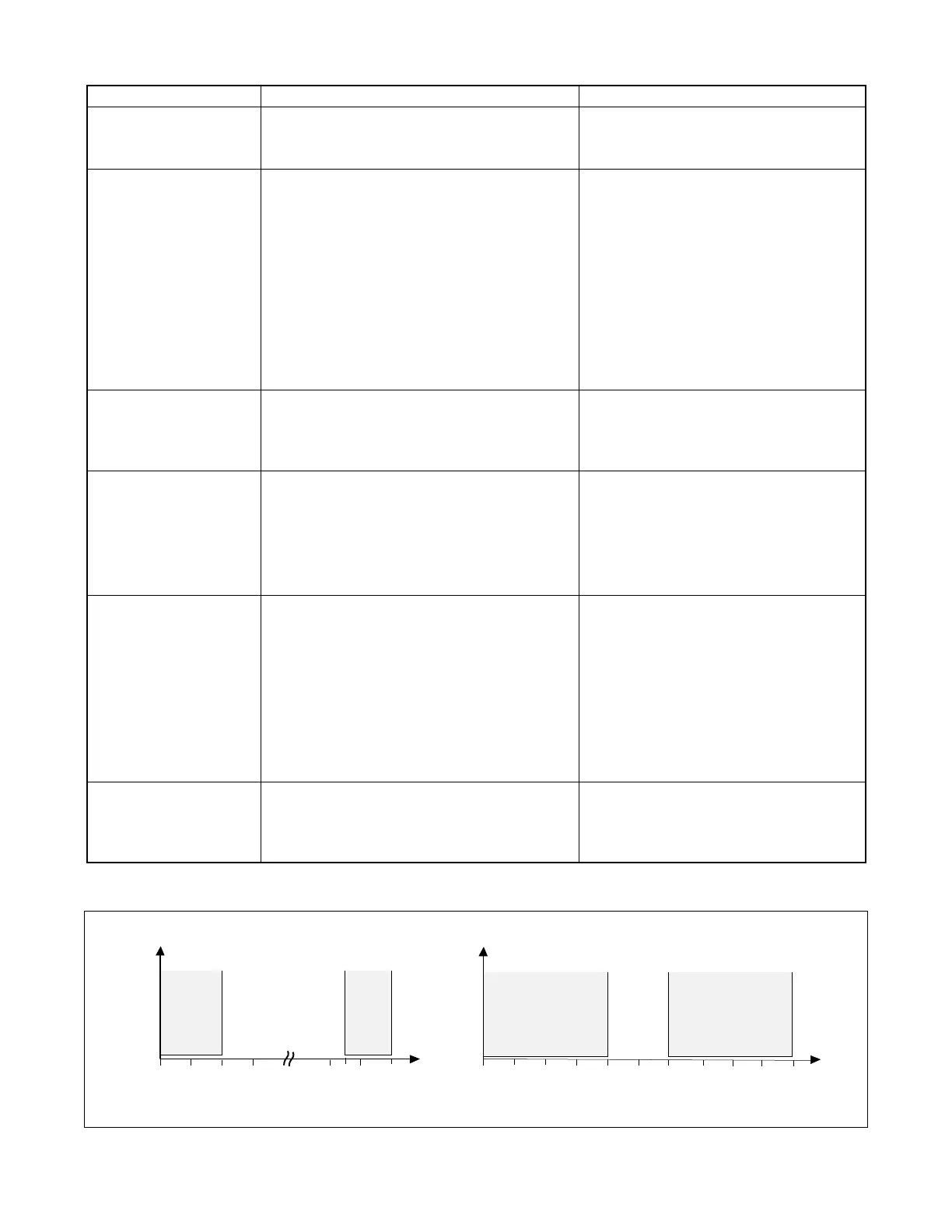

Figure 14: Adjustable Switching Range

Troubleshooting Logix 500 Digital Positioners

Factory setting of the limit switches LS1 and LS2: 0% – 3% from the end position

0 10 20 30 80 90 100%

0 10 20 30 40 50 60 70 80 90 100%

85

0

Rotary Version

LS1

LS2

LS1

LS2

Switch output

Switch output

Linear Version

Stroke

Rotary angle

Loading...

Loading...