Valtek GS General Service Valve FCD VLENIM0300-00-A4 08/14

16

Turn the hex nut (113) from the bellows seal assembly

(6) counter clockwise to loosen, remove the seal car-

rier (91) and profile ring (60) then move the bellows

seal assembly down and out.

NOTICE

The bolting between plug and stem

are secured against twisting. Type A

and B bellows seal assemblies are secured with a lock

bushing (8).

12. Use the Packing Driver Tool (See Section 16: Special Tools)

to remove the packing (88) and the packing box ring (93).

13. Use a standard brass scraper or other suitable tool to

remove all old gasket material; then clean the gasket

surfaces.

NOTICE

Examine the valve trim and bon-

net components. If the nominal and

actual values differ by more than 5% a control valve

overhaul may be required.

14. Check stressed surface areas for damage such as

scoring or deformities.

15. Use a standard brass scraper or other suitable tool

to clean all bolting. Check for corrosion or any other

damage.

Reassembly of the valve with a Bellows Seal

Bonnet Assembly:

16. Lubricate all bolt and screw threads and bearing sur-

faces (stem, plug, underside of the nuts) with a suit-

able, approved lubricant (See Section 15: Lubricants).

NOTICE

Never allow lubricants to come in

contact with the bonnet or sealing

surfaces.

17. Install and finger tighten a new profile ring (55) and

seat ring (20).

18. Insert the Seat Change Tool (See Section 16: Special

Tools) into the body of the valve and turn clockwise

using a suitable torque wrench (See Section 14: Re-

quired Torque, for screwed seats).

19. Lower the plug (50) into a three jaw-chuck with soft

brackets and install a new lock bushing (8) into the

plug (Type A and B).

NOTICE

The cone of the lock bushing must

open to the top.

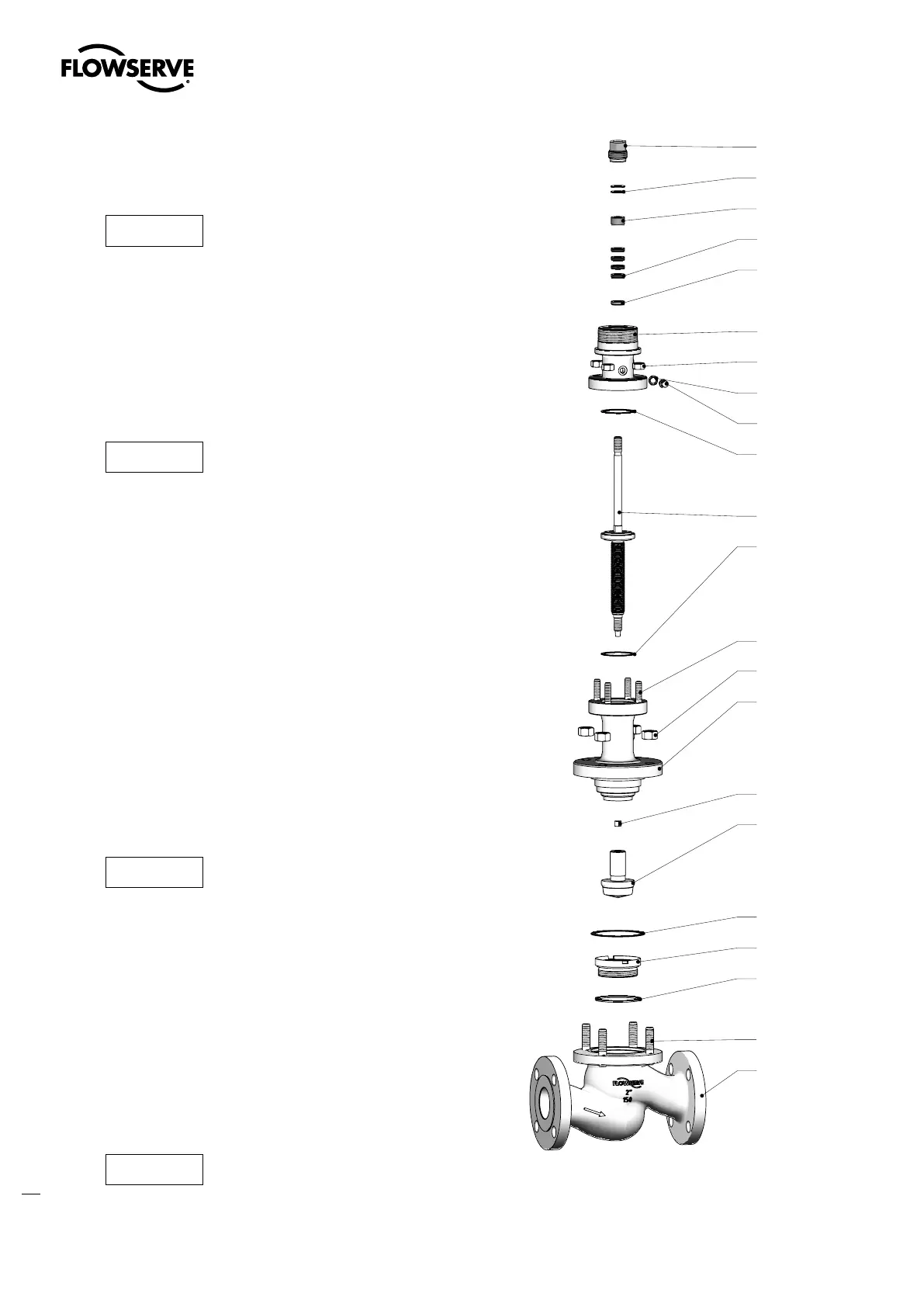

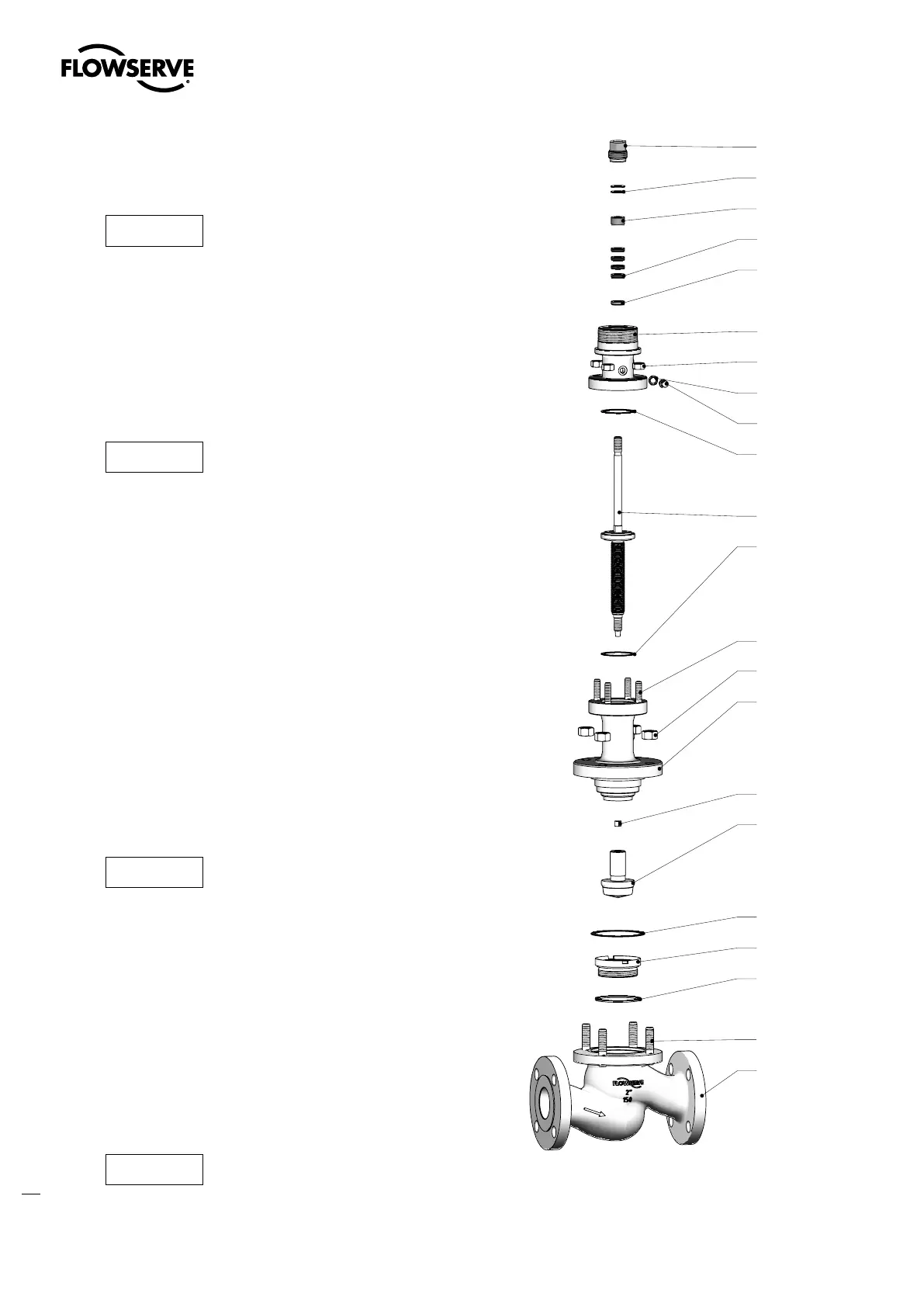

1

108

55

58

20

50

8

40

114

59

6

59

42

48

7

93

88

87

109

80

Figure 10: Disassemble / Reassemble the valve with bellows seal assembly

for type A designs (Valve parts see Table 13, Page 17)

Loading...

Loading...