1-8

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Tighten the stem clamp bolting. Proper tightness is

important since this adjustment secures the actua-

tor stem to the plug stem. Adjust the stroke plate so

the stem clamp points to the “closed” position.

12. If the valve has been taken out of the line, make sure

the flow arrow indicates proper flow direction upon

reinstallation.

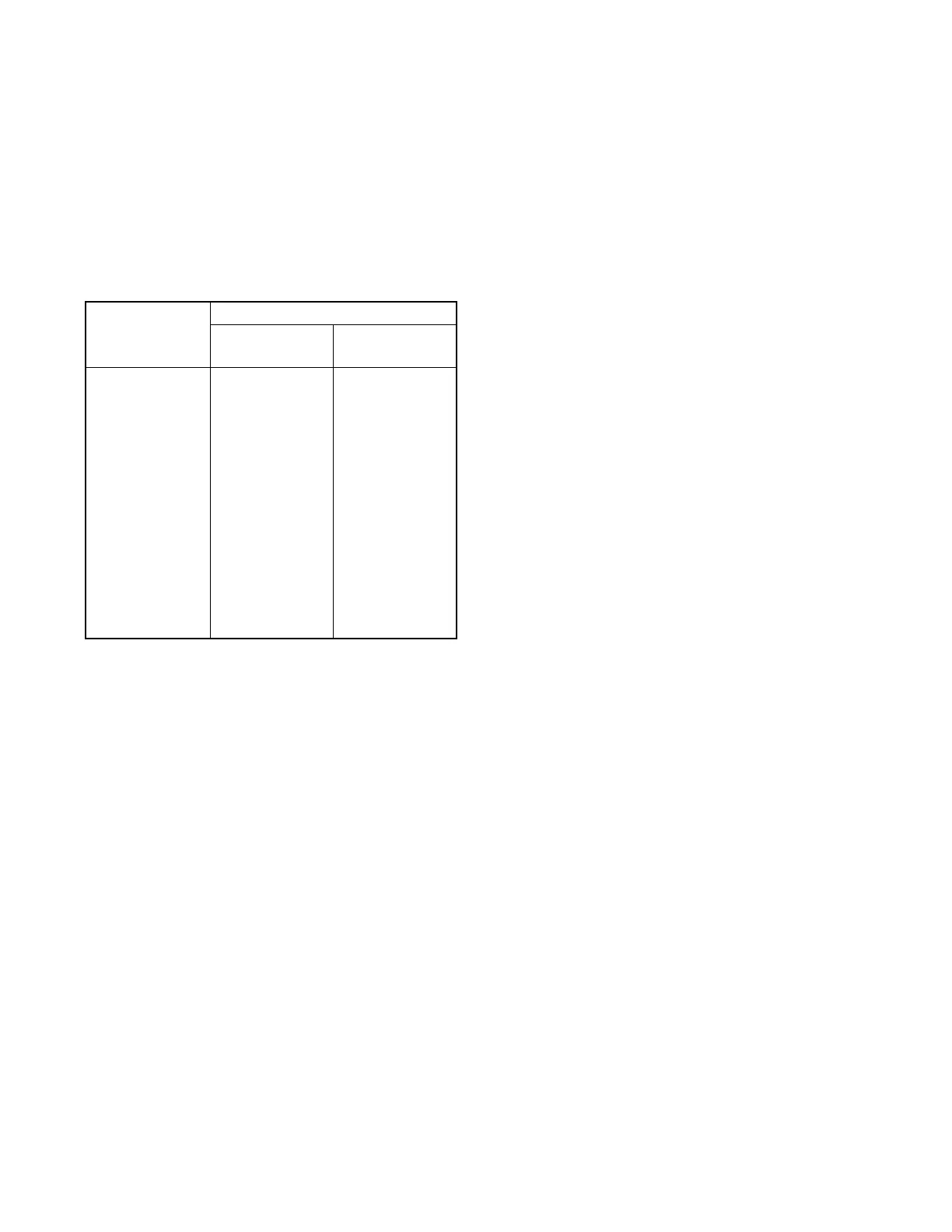

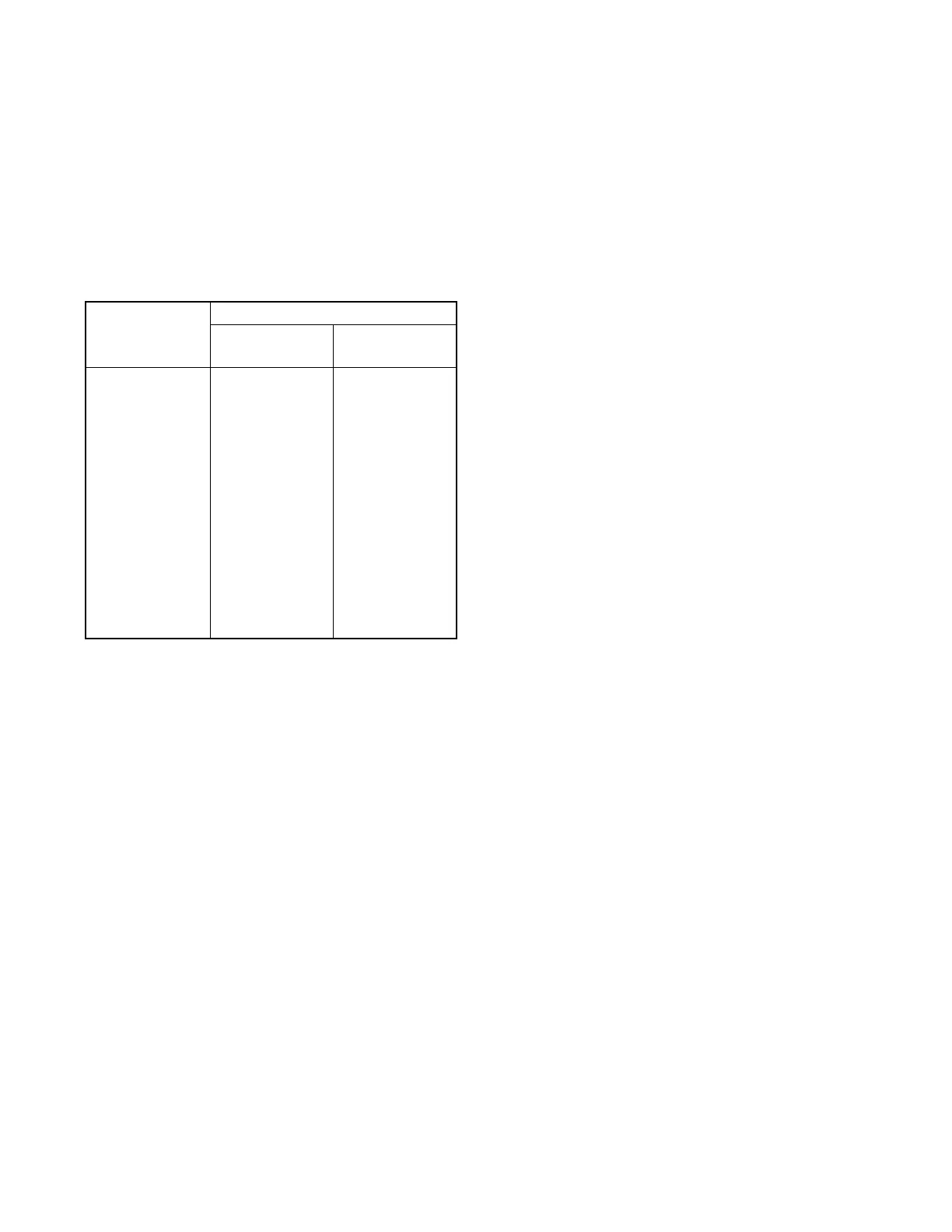

Table III: Suggested Bonnet Bolting

Torque Values (ft-lbs / Nm, ±10 percent)

Bolt

Size Carbon Stainless

(inches) Steel Steel

5

/8 80 / 108 50 / 68

3

/4 140 / 190 90 / 122

7

/8 230 / 312 150 / 203

1 350 / 475 220 / 298

1

1

/8 510 / 690 330 / 447

1

1

/4 730 / 990 460 / 624

1

3

/8 990 / 1342 630 / 854

1

1

/2 1320 / 1790 840 / 1140

1

5

/8 1710 / 2318 1080 / 1484

1

3

/4 2170 / 2942 1400 / 1898

1

7

/8 2700 / 3660 1700 / 2305

2 3350 / 4542 2100 / 2847

Disassembling the Actuator

With air-to-open valves, the actuator may be disas-

sembled while on the valve. With air-to-close valves,

the actuator must be removed from the valve prior to

disassembly. To disassemble the actuator, refer to

Figures 1, 3 and 5 then proceed as follows:

NOTE: Steps 1 through 4 apply to removing the actua-

tor from the valve. If disassembly is to take place with

the actuator still attached to the valve, go on to step 5.

1. Make sure the plug is neither seated on the seat ring

nor back-seated against the bonnet by attaching an

air hose on the appropriate side of the cylinder and

release the pressure on the opposite side.

CAUTION: Galling of critical surfaces may re-

sult if the plug is not positioned correctly be-

tween the seat ring and bonnet.

2. Loosen the stem clamp.

3. Remove packing box bolting and yoke clamps.

4. Completely turn the actuator off the plug and bon-

net without rotating the plug inside the bonnet.

CAUTION: Do not allow the plug to drop and

impact against the seat after turning the actua-

tor off the plug threads.

5. Disconnect tubing.

6. Remove the adjusting screw to relieve the spring

compression.

WARNING: The spring compression must be

relieved before further disassembly; other-

wise, serious personal injury can occur dur-

ing disassembly.

7. Remove the retaining ring from the groove at the

base of the cylinder by using two screwdrivers,

inserting them in the ring’s slot and prying the ring

from the groove.

8. Pull the cylinder off of yoke and piston. Some O-ring

resistance may be felt. Remove spring for cleaning

and inspection (air-to-open configuration only).

WARNING: Do not use air pressure to remove

cylinder. Serious personal injury can occur.

9. To remove the spring on air-to-close configura-

tions, remove the piston retaining nut and slide

piston off of the actuator stem. The spring may now

be removed.

NOTE: Step 10 can only be performed if the actua-

tor has been removed from the valve.

10. To inspect the actuator stem O-ring, remove the

stem clamp and bellows. Push the actuator stem

through the yoke, being careful not to gall the stem.

The O-ring may now be removed for replacement.

NOTE: The actuator stem bushings are pressed

into the yoke; it is not necessary to remove the

bushing to replace the actuator stem O-ring.

Reassembling the Actuator

To reassemble the actuator, refer to Figures 1, 3 and 5

then proceed as follows:

1. All O-rings should be replaced and the new ones

lubricated with a silicone lubricant (Dow Corning

55M or equivalent). Silicone O-rings must be lubri-

cated with Magnalube-G lubricant or equivalent. Do

not use a silicone lubricant on silicone O-rings.

2. Make sure all internal parts are thoroughly cleaned

and lubricated before beginning reassembly.

3. If the actuator stem has been removed, replace the

piston stem O-ring and reassemble the piston and

actuator spacer on the actuator stem according to

the proper air-action (refer to Figures 3 and 5.) Air-

to-close configurations require the spring button to

be inserted under the actuator stem retaining nut.

Tighten the retaining nut firmly.

4. For air-to-close configurations, place the spring

under the piston and insert the actuator stem

through the yoke, being careful to not gall the stem

Bolt/Stud Material

Loading...

Loading...