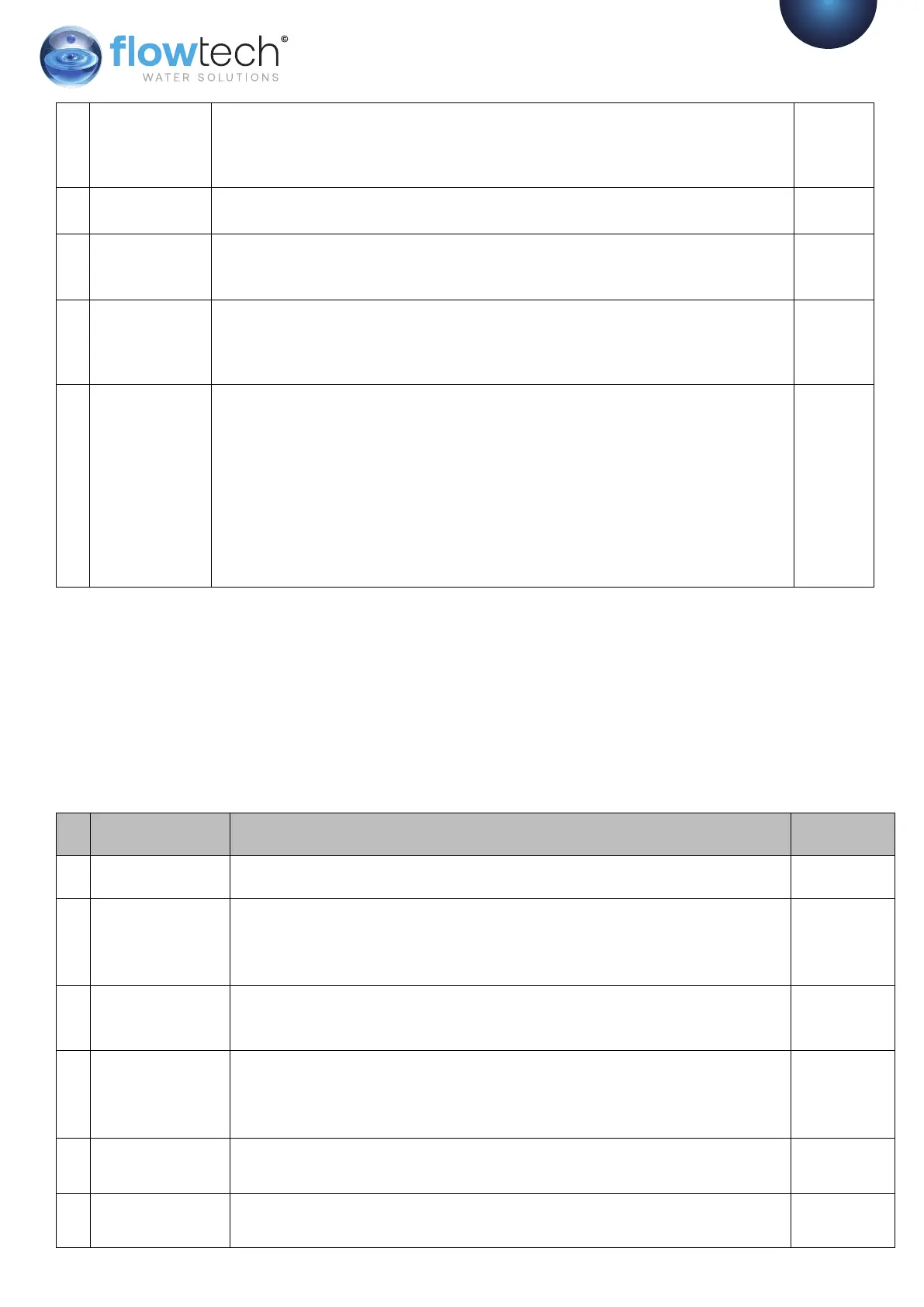

11

POWER

INTERRUPTED

The cumulative number of power interruptions (i.e. controller turned o/power cut).

This is a cumulative counter, the value of which cannot be modified. If using the

engineer’s code, the counter can be reset to zero by holding the (MUTE) buon.

-

12 PULSE

When enabled, if a pump has been inactive for 60 days, it will start and run for

2 seconds. This is to prevent the pumps from seizing.

YES

13

EXCESSIVE

START

When enabled, if there are more than 3 individual pump runs within an 8 hour

period, the unit will register an <EXCESSIVE DEMAND> alarm. Enabling this option

may cause false alarms on some systems.

NO

14 SERVICE

When enabled, a service reminder will be displayed aer 12 months from when the

option was enabled.

To reset the service reminder, set the value to ‘NO’ and exit the menu. Then, re-enter

the menu and set the value to ‘YES’ again.

NO

15 FILL SYSTEM

When enabled, the <LOW PRESSURE> and <FLOOD LIMIT> alarms will be disabled,

and pump 1 will run continuously for up to 24 hours until the cold fill pressure has

been reached.

Once the cold fill pressure has been reached, this option will automatically be

deactivated, and the low pressure alarm and flood limit will be reactivated. This

function is used to fill a system that is empty or at low pressure.

Care must be taken using this option as the flood limit alarm is disabled, increasing

the risk of flooding.

This option cannot be enabled on Mini pressurisation units.

NO

If using the customer code, the menu will end at this point. Aer pressing (SET) once more, the controller will

display “SAVING...” and return to normal operating mode. If using the engineer’s code, additional menu items

will be displayed.

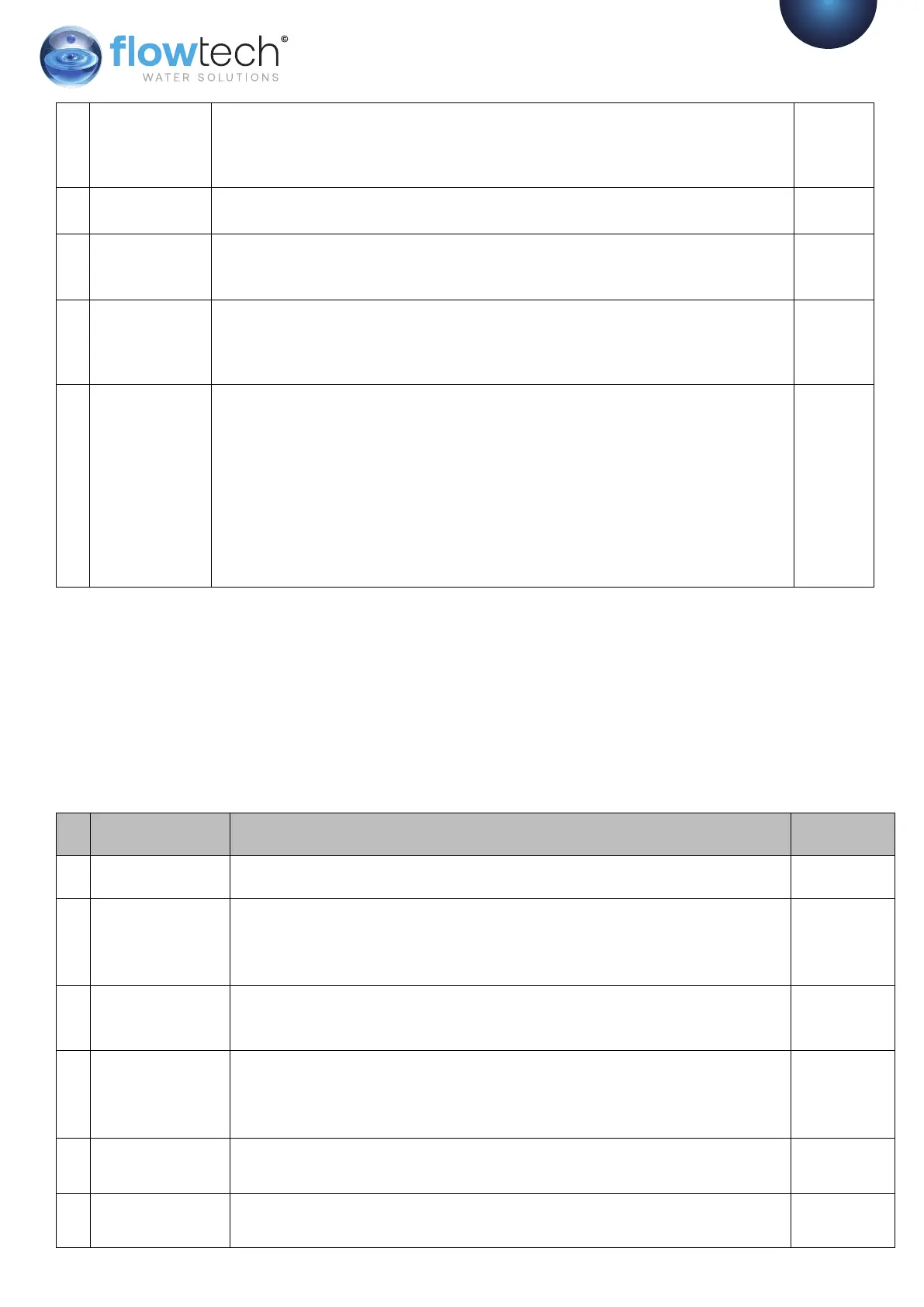

The following seings are all pre-programmed in the factory and should not need to be modified on site. If

these seings appear to have been reset, the most likely cause is a power spike. If this problem persists, a

power filter may be required.

The following seings are for experienced engineers only. Incorrect configuration of these seings can cause

the equipment not to function correctly, and may cause damage to the equipment, system or property.

# Menu Item Function Default

Value

16 PUMPS NUMBER The number of pumps installed in the pressurisation unit.This can be set to either

1 or 2.

2

17 PUMP TYPE The type of pump installed in the pressurisation unit.

There are two options, which are as follows:

0 – Centrifugal Pump

1 – Piston Pump

0

18 PUMP SENSE Disabling this option will stop the controller from monitoring the pumps and

generating <PUMP FAIL> faults.

It is not recommended to disable this option.

YES

19 SENSOR TYPE The type of pressure sensor installed in the unit.

There are two options which are as follows:

1 – 1-6V Output, 0-10 Bar Range

2 – 1-6V Output, 0-16 Bar Range

1

20 SPC

CONTROLLER

Not required on standard Pressurisation unit NO

21 ADDITIVE Not required on standard Pressurisation unit NO

18

Loading...

Loading...