20

Service contract

Flygt or its agent normally offers service agreements

in accordance with a preventive maintenance plan. For

further information, please contact your Flygt repre-

sentative.

Ex-approved machine!

All work on the explosion-proof

motor section must be performed by

personnel authorized by Flygt.

Oil in

▲▲

▲▲

▲

Oil out

▲▲

▲▲

▲

Major overhaul

This requires special tools and should be done by an

authorized service shop. Workshop overhaul involves

in addition to the inspection, that the following will be

measured;

— replacement of bearing.

— replacement of the plug-in seal..

— replacement of oil.

— replacement of O-rings.

— replacement of seals in cable entry and moving the

entry position of the cable.

— replacement of cable.

Recommended inspections

Inspection of Action

Visible parts on mixer Replace or fix worn and damaged parts.

and installation Make sure that all screws, bolts and nuts are tight.

Check the condition of lifting device/lifting eyes, chains and wire ropes.

Check that the guide bar is vertical.

Replace worn parts if they impair function.

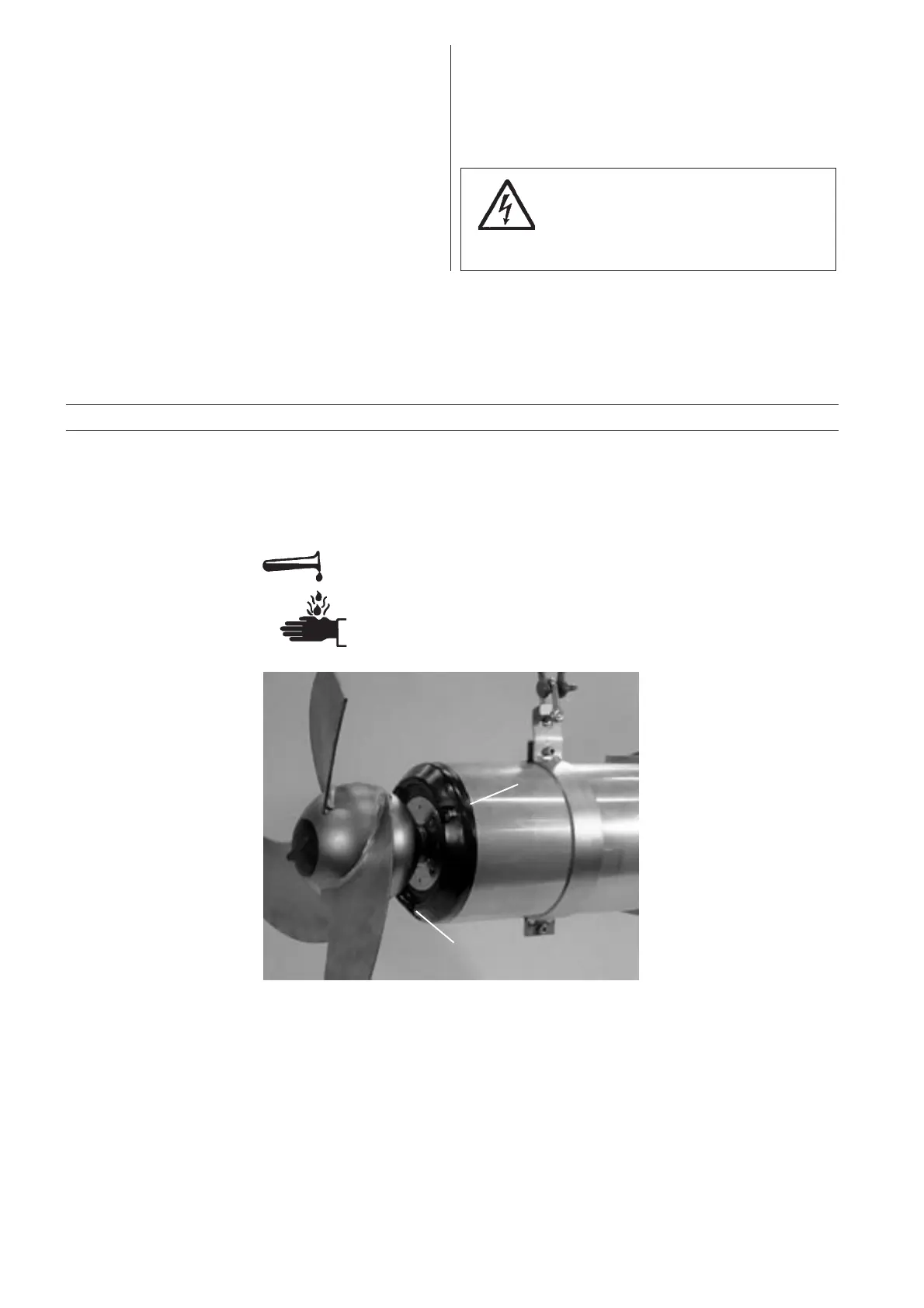

Oil quantity WARNING. If the seal leaks, the oil casing may be under

pressure. Hold a rag over the oil casing screw in order to prevent

splatter. See “Safety precautions” for additional information.

Check that the oil level minimum reaches up to the centrumline of the shaft.

A check of the condition of the oil can show whether there has been an increased

leakage. Check the oil by removing the oil drainage screw. Leave the oil filling

screw in place in order to restrict the flow. As the oil separates the water, the liquid

coming out first will indicate a possible leakage. Tap until clear oil is coming out.

If leakage less than 0.1 ml/h, the seal functions normally. Refill the tapped volume

with new oil. See “Changing the oil”.

If the leakage is more than 0.1 ml/h, refill the oil. Run the mixer for one week and

check the oil again. If leakage is more than 0.1 ml/h the fault may be:

— that the outer mechanical seal is damaged. Contact a Flygt service shop.

Loading...

Loading...