13

PP-pump installation

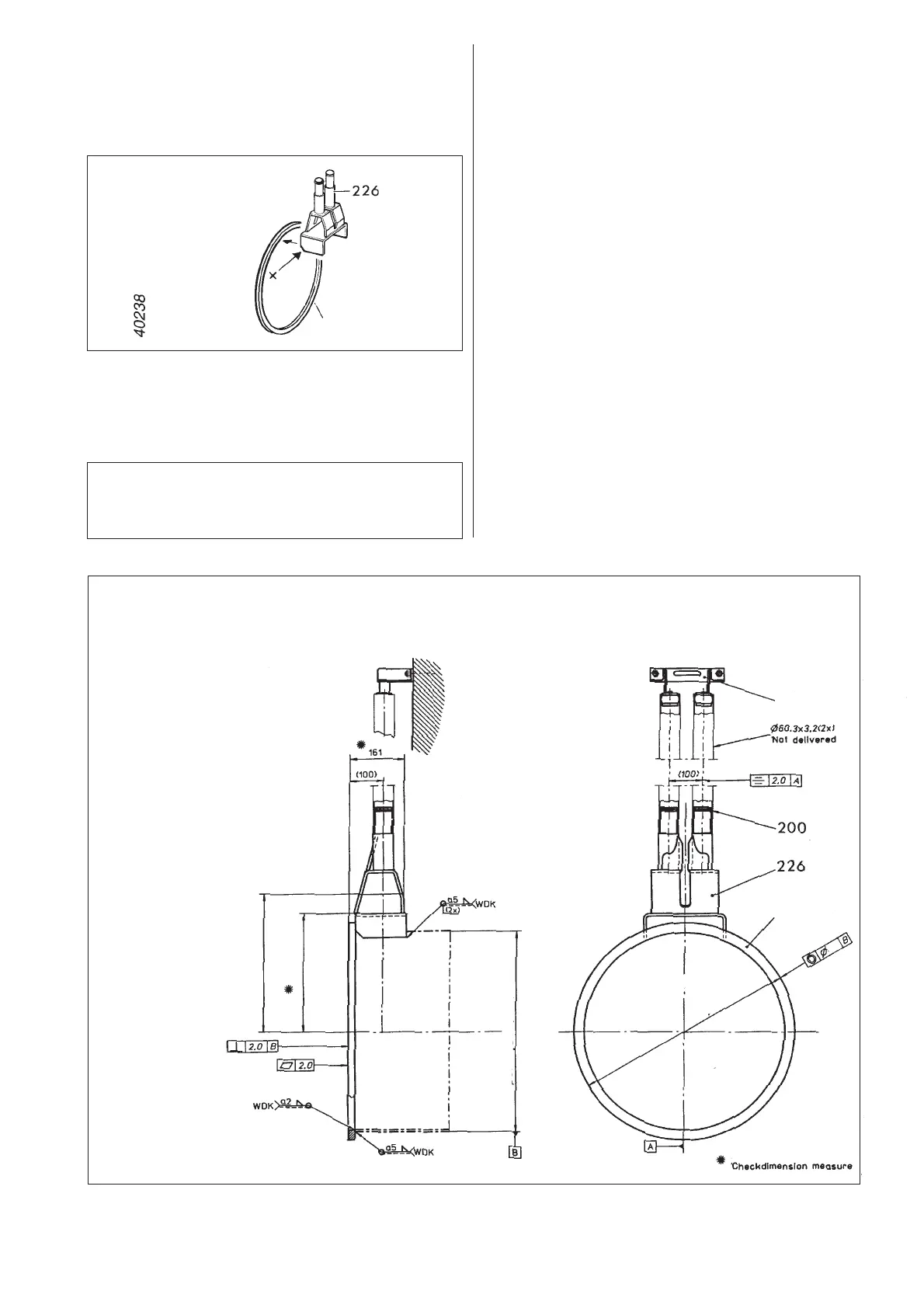

Mark out the location of the discharge connection on

the wall.

Drill a hole in the wall (a little wider than the diameter

of the tubes).

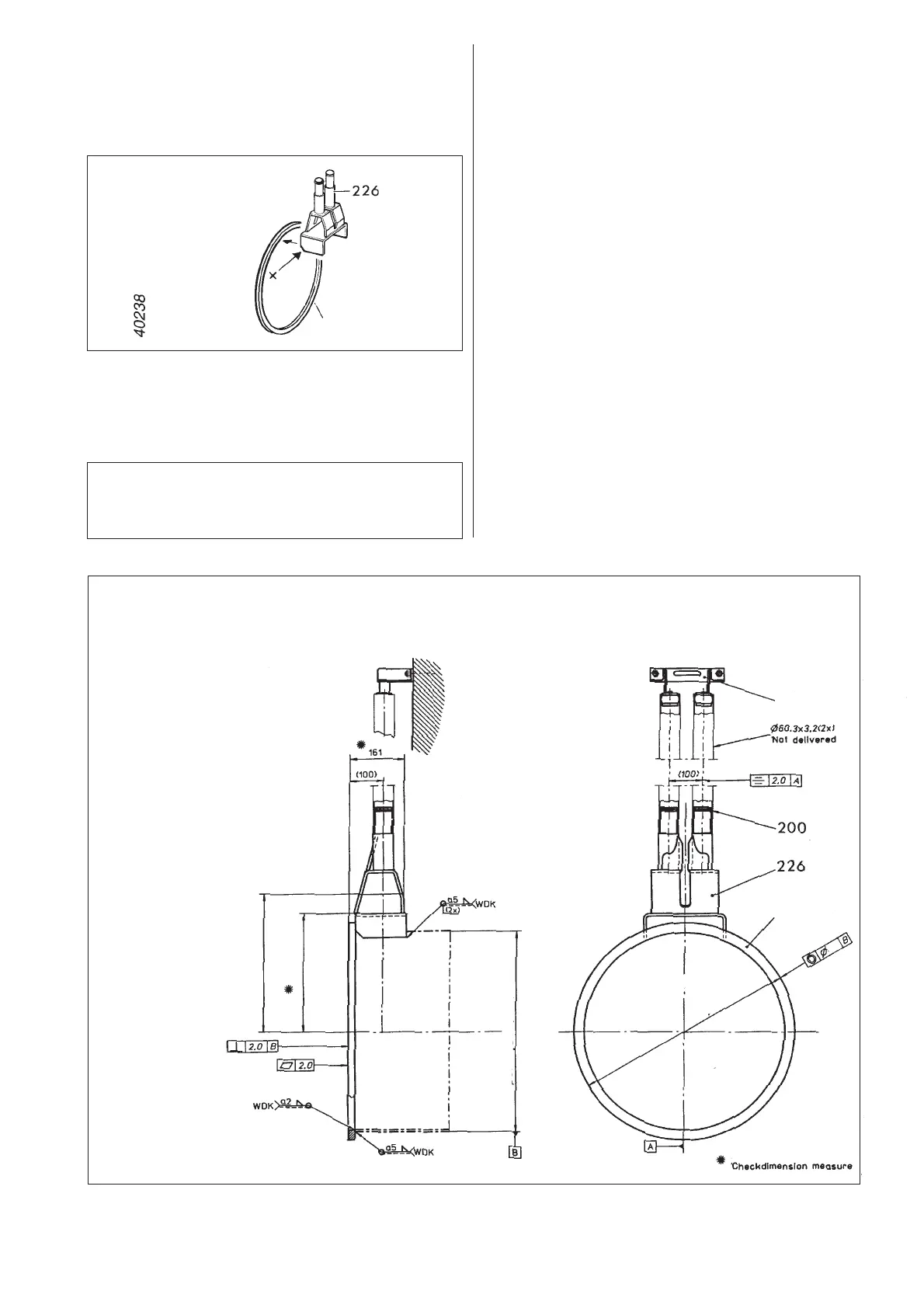

Weld together the bracket (226) and the ring (225).

NOTE! Place the bracket with the sloping (x) towards

the ring.

Centre the ring to the tube and weld the ring and

bracket together with the tube.

NOTE!

All welded joints must be pickled and polished

before they come into contact with the liquid.

The tube must have a diameter A and a wall diameter B.

4630, 4640 A 406.4 mm (16") B 6.3 mm (0.25")

4650, 4660 A 609.6 mm (24") B 6.3 mm (0.25")

4670, 4680 A 812.8 mm (32") B 8.0 mm (0.31")

NOTE! It is important that the ring is welded perpen-

dicular to the tube.

Place the unit in the wall.

Carefully measure the correct guide bar length. Cut

the bars to the right length. The guide bars must have

a diameter of 60.3 mm (2.37") and a wall thickness of

3.2 mm (0.13").

Place the guide bars on the bracket, don´t forget the

O-rings (200).

Put the guide holder unit (227) on the guide bars and

mark the location of the guide holder on the wall.

Drill holes and tap in expansion bolts. Place the guide

holder and guide bars in position, tighten the bolts.

Measure the centre-to-centre distance between the

guide bars, which should be 100 mm.

It is important that the guide bars are mounted

vertical, use a plumb line.

Tighten around the tube and check that the discharge

connection will be fixed in the wall.

4630, 4640

AB Ø 406 (DIN2458 Ø 406.4 x 6.3)

C Ø 460

D3.0

E 299

F 240

4650, 4660

AB Ø 610 (DIN2458 Ø 609.6 x 6.3)

C Ø 660

D4.0

E 417

F 358

4670, 4680

AB Ø 813 (DIN2458 Ø 812.8 x 8.0)

C Ø 870

D4.0

E 521

F 462

40279

E

F

Ø C

D

Ø AB

225

227

225

Loading...

Loading...