17

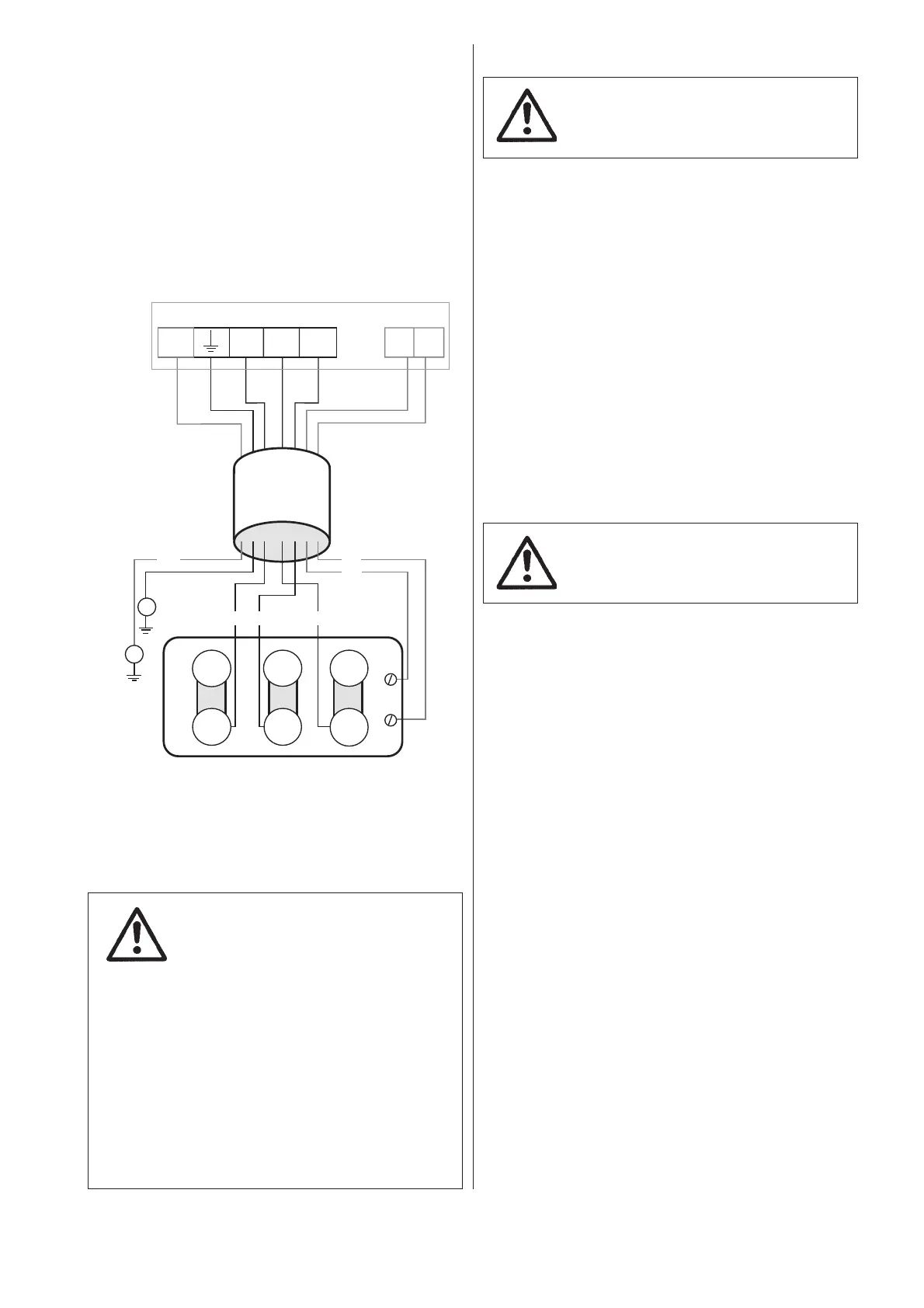

CABLE

GC

GC

T1

T2

W2

V2

U2

L2 L3 T1 T2L1

GC

3~

D - connection

4670 - 4680

L3L1 L2

V1 W1

T1

U1

T2

Stator leads

Stator leads Connection

terminal board

Red U1

Brown V1

Yellow W1

Green U2

Blue V2

Black W2

Direct on line start

If persons are likely to come into

physical contact with the machine

or mixed/pumped media (liquid),

e.g. on farms etc, the earthed

(grounded) socket must have an additional

earth-(ground-) fault protection

device (GFI) connected.

When mixing/pumping near a lake (jetties,

beaches and ponds etc) a safety distance of at

least 20 meters (65 ft) between the person and

the machine is necessary. The machine must

never be placed directly into a swimming pool.

If used in connection with swimming pools,

special safety regulations apply.

Monitoring equipment

Make sure that the monitoring

equipment incorporated in the

product is correctly connected.

Capacitive leakage sensor CLS-30 and

leakage sensor FLS (built in version).

The machine is available with leakage sensors for

sensing water in the oil and/or the stator casing.

A plate in the junction box shows that the machine is

equipped with sensors.

CLS-30 is a leakage sensor for sensing water in the oil

casing and issues an alarm when the oil contains 30%

water. Oil change is recommended within 14 days of

alarm. If the sensor issues an alarm shortly after the oil

is changed, contact your nearest Flygt representative.

The CLS-30 sensor is installed in the bearing housing

and goes down into the oil casing. Available for 4650

to 4680. The CLS-30 sensor is not applicable to Ex-

approved machines.

Observe that the CLS cover is

made of glass and can cause

personal damage.

The FLS sensor consists of a small float switch for

sensing water in the stator casing.

The FLS sensor is installed in the bottom of the stator

casing.

The two sensors, CLS-30 and FLS, can be used in the

same machine. They are connected in parallel. Follow

the instruction for monitoring equipment.

Loading...

Loading...