Fault in bimetals in motor

Replace defective bimetals (over current

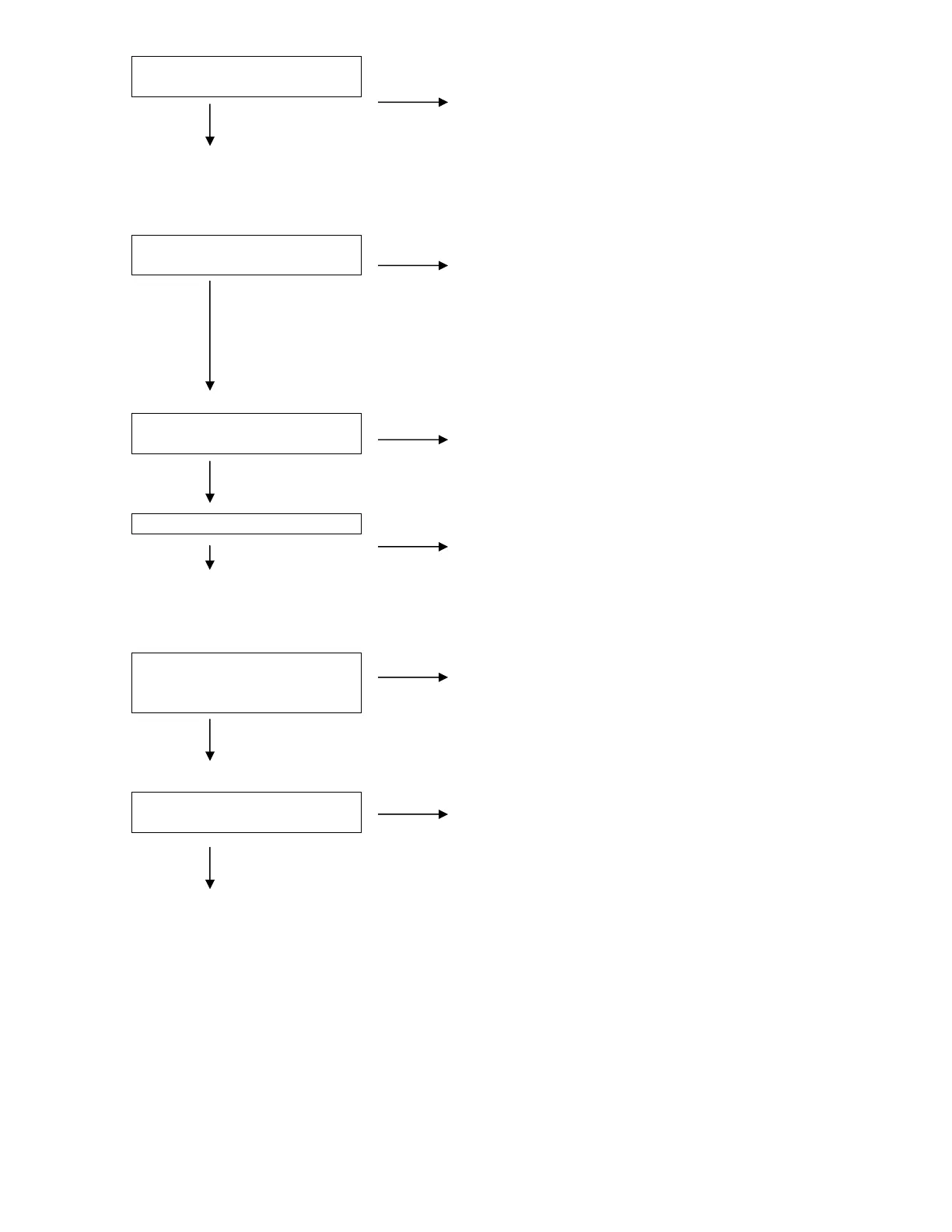

3. The pump does not stop.

Is the pump able to empty

the station to the stop level?

- for leakage in pipe and/or discharge

- that the impeller is not clogged.

WARNING: disconnect power before

- the non-return valve(s).

- that the pump has adequate capacity.

Check the contactor and holding circuit.

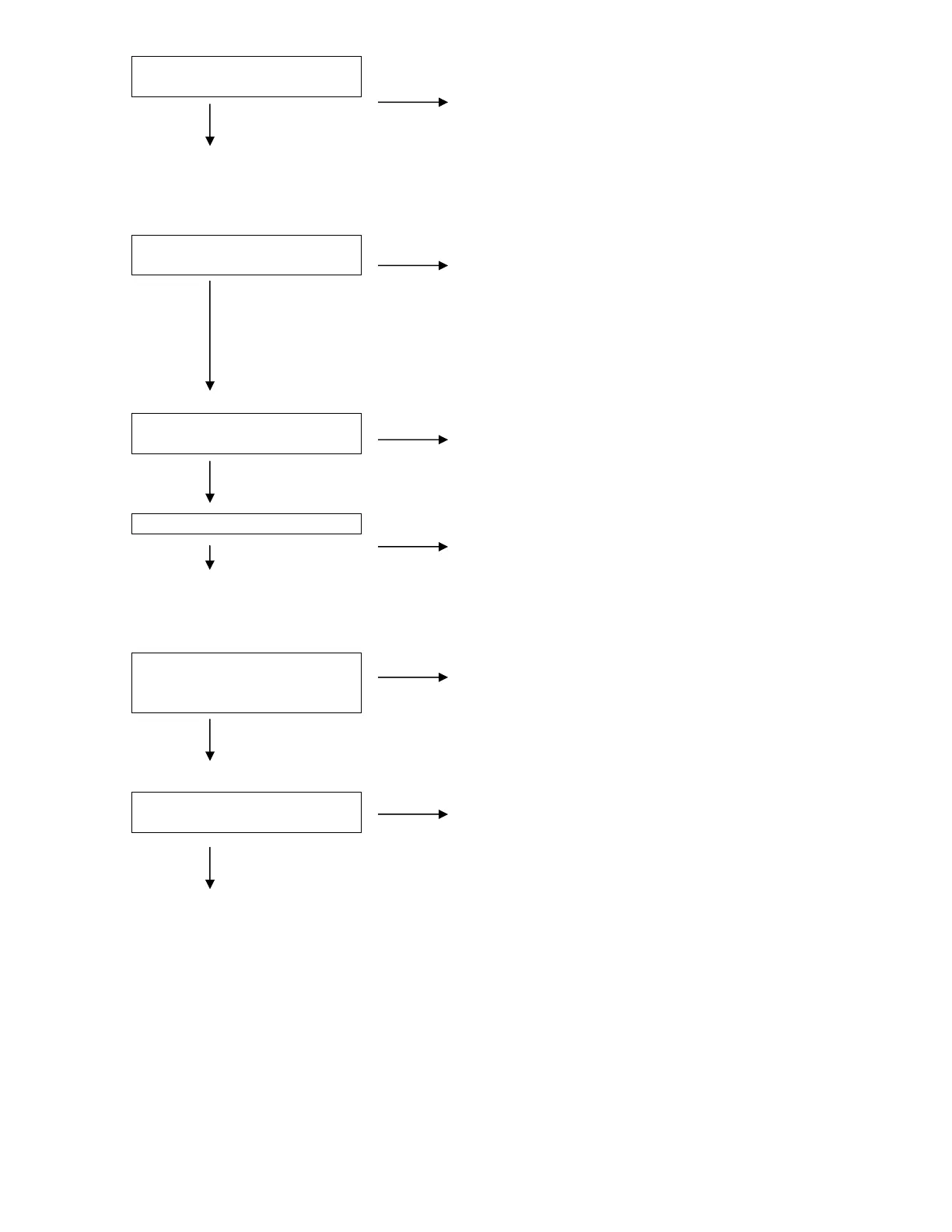

4. The pump starts-stops-starts in rapid sequence

Does the pump start due to

backflow which fills sump to

- that the distance between the start and stop

- the non-return valve(s).

- that the riser is not too long without a

Does the contactor’s self-

- the voltage in the control circuit in relation

to the rated voltage on the coil.

5. Pump runs but delivers too little or no water.

Check:

- direction of rotation pump.

- that valves are open and intact.

- that pipes, impeller and strainer are not clogged.

- that the impeller rotates easily.

- that the suction lift has not been altered.

- for leakage in the pump installation.

- for wear on wear ring, impeller, pump casing/flange, suction bottom, diffuser, disc, diffuser.

See also under “Inspection”.

Do not override the motor protection repeatedly if it has tripped.

Loading...

Loading...