Air Venting:

Air tends to trap in the pump volute when water raises in the sump or when the pump is lowered into water after

service. To vent off this air, a small hole is drilled into the pump volute. Be sure this vent hole is clean after any

service work on pump.

Motor Overload Protection – The motor is provided with an on-winding overload switch. If motor overloads or

overheats for any reason, the switch opens stopping motor. As soon as the motor cools to normal temperature the

switch closes and restarts the motor.

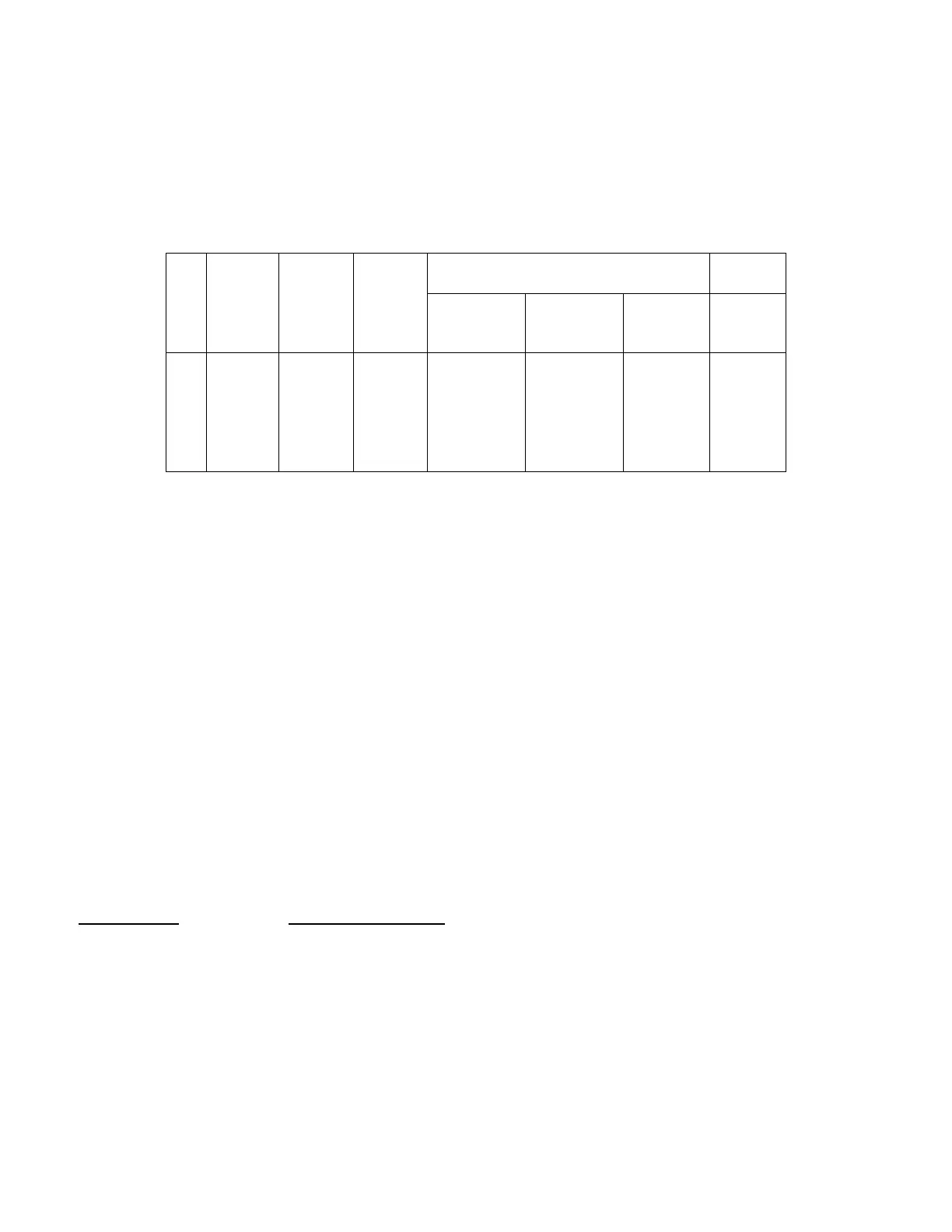

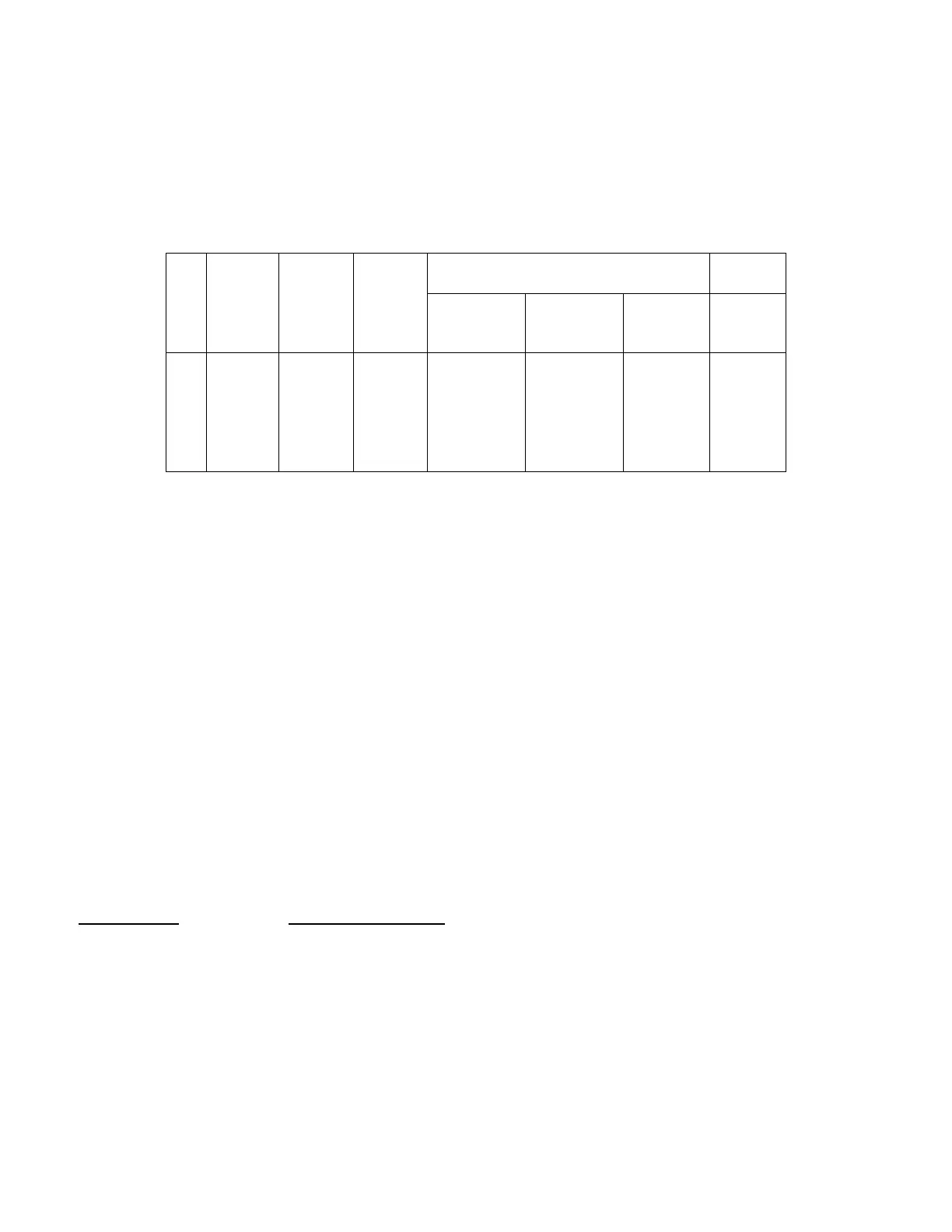

MAXIMUM AMP & WINDING RESISTANCE VALUES

WINDING RESISTANCE IN

OHMS

*50 Hz

If amp readings are higher than listed, it indicates voltage may be higher or lower than normal or that pump grinder

may be clogged with trash causing extra load on motor.

CHECK LIST IF PUMP DOES NOT OPERATE PROPERLY

CHECKING FOR MOISTURE IN MOTOR – Use ohmmeter and set on highest scale. Readings on the large

power cord between any of the conductors red, black, white to green conductor or motor shell should be more than

500,000 ohms. Motor probably will run with a lower reading, but if pump is out of service and reading is below

500,000 ohms the motor housing and stator should be removed and baked in a drying oven at 220°F. To be

serviced only at authorized service station.

RESISTANCE OF WINDINGS – Every motor winding has a fixed resistance and winding must check close to

the values given below to operate properly. This winding resistance also shows if motor is connected for voltage

being used. Use ohmmeter for this test and set on scale to read directly in ohms.

TROUBLE CHECK LIST

Troubles listed are generally caused by the pump. Other troubles can occur form a faulty control box. Those will

be listed with the control box instruction.

CONDITION PROBABLE CAUSE

Pump runs but does not 1. Pump impeller may be air locked, this occasionally occurs on a new

pump liquid from basin. installation. Start and stop pump several times to purge air.

2. Run additional water into basin so that pump will be submerged deeper to clear

water.

3. If air does not clear it may be necessary to lift pump out of sealing elbow and start

motor to allow pump to pump for a few seconds. If discharge is piped in with

union, slightly break union and start pump to clear air. Air vent hole is provided in

pump case, so some water will flow from this hole when pump is operating. If

vent hole gets clogged, clean out.

4. If pump has been installed for some time and does not pump, it may be clogged at

the grinder inlet.

5. Discharge gate valve may be closed.

6. Discharge check valve may be clogged or have a broken clapper.

Loading...

Loading...