Paragraphs 93-95

FORD

Check rectifier diodes by touching one

tester lead to diode terminal and touch

other lead to rectifier frame, then re-

verse test lead connections. The diodes

should show continuity in one direction

and high resistance in the other direc-

tion. If one or more diodes has high re-

sistance in both directions or low re-

sistance in both directions, renew rec-

tifier assembly.

Refer to the following specifications

for rotor and brush wear limits.

Models 1100-1110-1200-1210-1300

Rotor Slip Rings

Minimum Diameter 31.7 mm

(1.248 in.)

Maximum Runout 0.05 mm

(0.002 in.)

Brush Length -

Minimum 5.5 mm

(0.217 in.)

Models 1310-1510-1710

Rotor Slip Rings -

Minimum Diameter 30 mm

(1.181 in.)

Maximum Runout 0.05 mm

(0.002 in.)

Brush Length -

Minimum 8.5 mm

(0.335 in.)

Models 1500-1700-1900

Rotor Slip Rings -

Minimum Diameter 30.7 mm

(1.209 in.)

Maximum Runout 0.05 mm

(0.002 in.)

Brush Length -

Minimum 7 mm

(0.275 in.)

Models 1910-2110

Rotor Slip Rings -

Minimum Diameter 31.3 mm

(1.232 in.)

Maximum Runout 0,05 mm

(0,002 in.)

Brush Length -

Minimum 9 mm

(0.355 in.)

When reassembling alternator, solder

stator wire connections using resin core

solder. Hold rectifier terminals with

needlenose pliers to absorb heat during

soldering operation. Quickly cool sol-

dered connection with a damp cloth to

protect rectifier diodes. To hold brushes

in retracted position during assembly,

push brushes into holder and insert a pin

or wire through holes in rear housing

and brush holder.

SAFETY START SWITCH

Models 1100-1110-1200-1210-

1300-1500-1700-1900

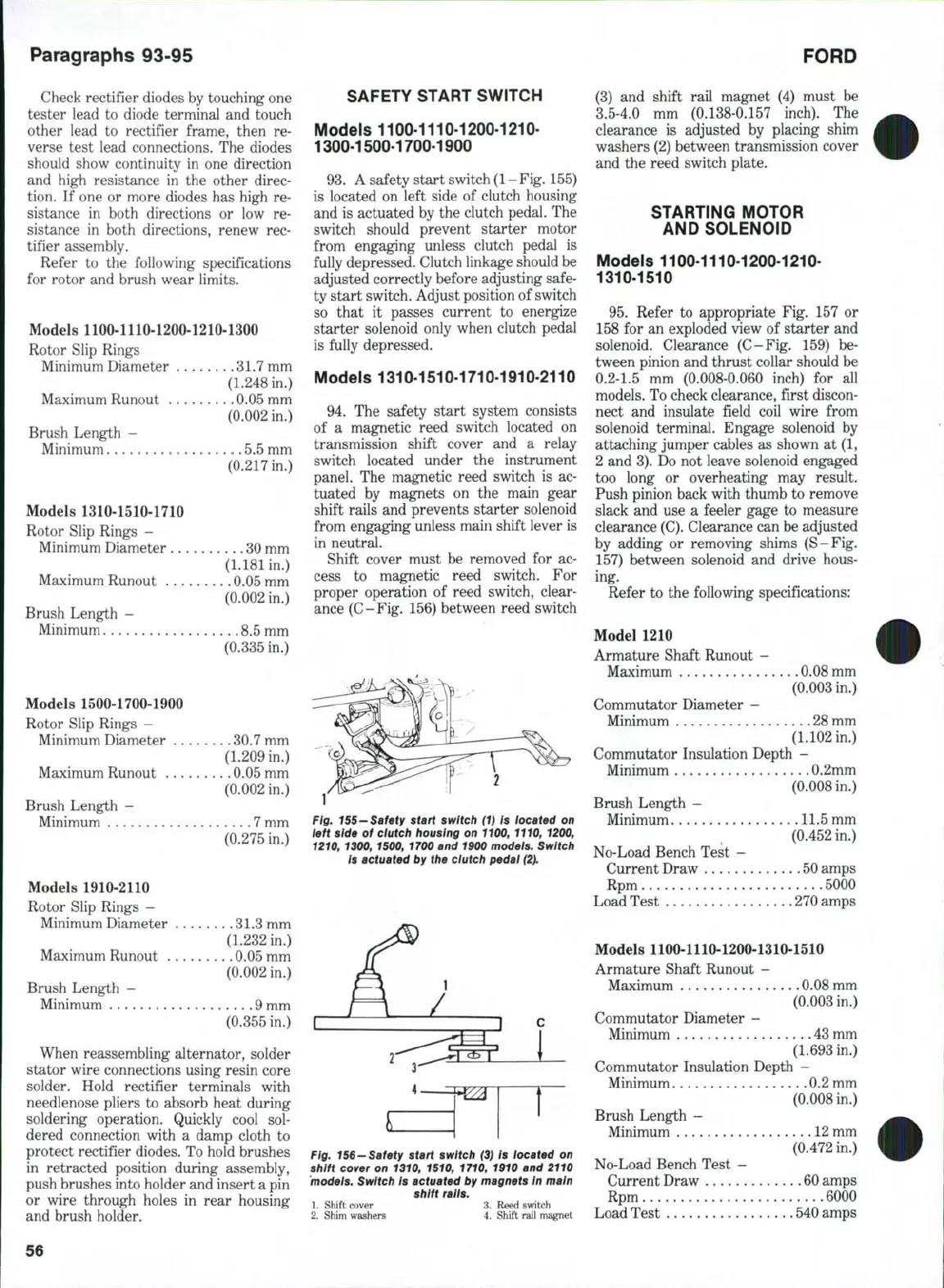

93.

A safety start switch

(1

-

Fig.

155)

is located on left side of clutch housing

and is actuated by the clutch pedal. The

switch should prevent starter motor

from engaging unless clutch pedal is

fully depressed. Clutch linkage should be

adjusted correctly before adjusting safe-

ty start switch. Adjust position of switch

so that it passes current to energize

starter solenoid only when clutch pedal

is fully depressed.

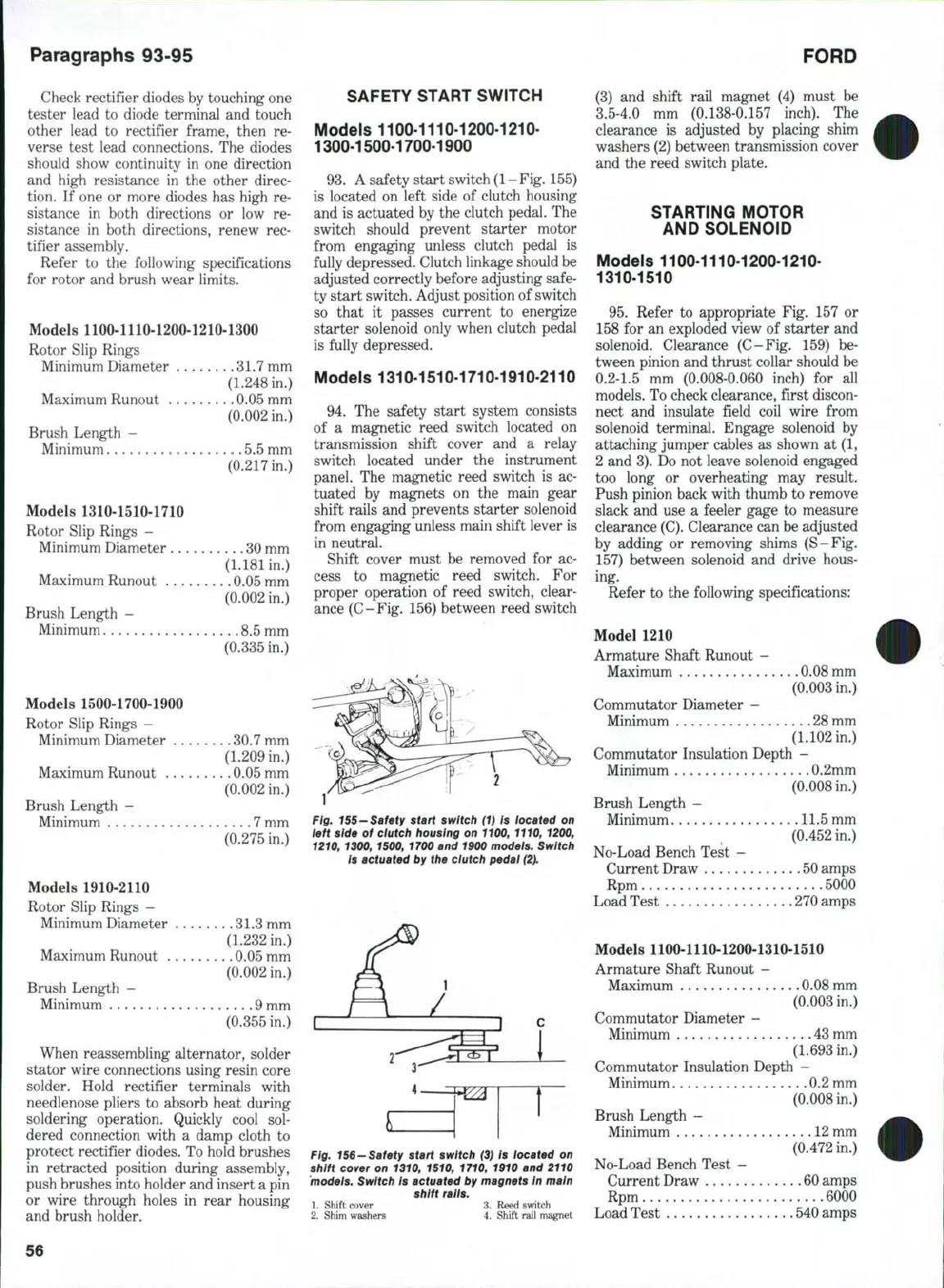

Models 1310-1510-1710-1910-2110

94.

The safety start system consists

of a magnetic reed switch located on

transmission shift cover and a relay

switch located under the instrument

panel. The magnetic reed switch is ac-

tuated by magnets on the main gear

shift rails and prevents starter solenoid

from engaging unless main shift lever is

in neutral.

Shift cover must be removed for ac-

cess to magnetic reed switch. For

proper operation of reed switch, clear-

ance (C-Fig. 156) between reed switch

Fig. i55-Safety start switch (1) Is located on

left side of clutch housing on 1100, 1110, 1200,

1210, 1300, 1500, 1700 and 1900 models. Switch

is actuated by the clutch pedal (2ji

1

2'

L

]

c

(

1

Fig. 156-Safety start switch (3) is located on

shift cover on 1310, 1510, 1710, 1910 and 2110

models. Switch is actuated by magnets In main

shift rails.

1.

Shift cover 3. Reed switch

2.

Shim washers 4. Shift rail magnet

(3) and shift rail magnet (4) must be

3.5-4.0 mm (0.138-0.157 inch). The

clearance is adjusted by placing shim

washers (2) between transmission cover

and the reed switch plate.

STARTING MOTOR

AND SOLENOID

Models 1100-1110-1200-1210-

1310-1510

95.

Refer to appropriate Fig. 157 or

158 for an exploded view of starter and

solenoid. Clearance (C-Fig. 159) be-

tween pinion and thrust collar should be

0.2-1.5 mm (0.008-0.060 inch) for all

models. To check clearance, first discon-

nect and insulate field coil wire from

solenoid terminal. Engage solenoid by

attaching jumper cables as shown at (1,

2 and 3). Do not leave solenoid engaged

too long or overheating may result.

Push pinion back with thumb to remove

slack and use a feeler gage to measure

clearance

(C).

Clearance can be adjusted

by adding or removing shims (S-Fig.

157) between solenoid and drive hous-

ing.

Refer to the following specifications:

Model 1210

Armature Shaft Runout -

Maximum 0.08 mm

(0.003 in,)

Commutator Diameter -

Minimum 28 mm

(1.102 in.)

Commutator Insulation Depth -

Minimum 0.2mm

(0.008 in.)

Brush Length -

Minimum 11.5 mm

(0.452 in,)

No-Load Bench Test -

Current Draw 50 amps

Rpm 5000

Load Test .270 amps

Models 1100-1110-1200-1310-1510

Armature Shaft Runout --

Maximum 0.08 mm

(0,003 in.)

Commutator Diameter -

Minimum 43 mm

(1.693 in.)

Commutator Insulation Depth -

Minimum 0.2 mm

(0.008 in.)

Brush Length -

Minimum

12

mm

(0.472 in.)

No-Load Bench Test -

Current Draw 60 amps

Rpm 6000

Load Test , 540 amps

56

Loading...

Loading...