142

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

YOUR CAR

SAFETY

STARTING AND

DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

BODYWORK

PROTECTION FROM

ATMOSPHERIC AGENTS

The main causes of corrosion are the

following:

❒

atmospheric pollution;

❒

salty air and humidity (coastal areas

or hot humid climates);

❒

seasonal environment conditions.

Not to be underestimated is also the

abrasive action of wind-borne

atmospheric dust and sand and mud and

gravel raised by other cars.

On your car, Ford implemented the

best manufacturing technologies to

effectively protect the bodywork against

corrosion.

These are the most important

technologies:

❒

Painting products and systems which

give the car particular resistance to

corrosion and abrasion;

❒

use of galvanised (or pre-treated)

steel sheets with high resistance to

corrosion;

❒

spraying the underbody, engine

compartment, wheelhouse internal

parts and other parts with highly

protective wax products;

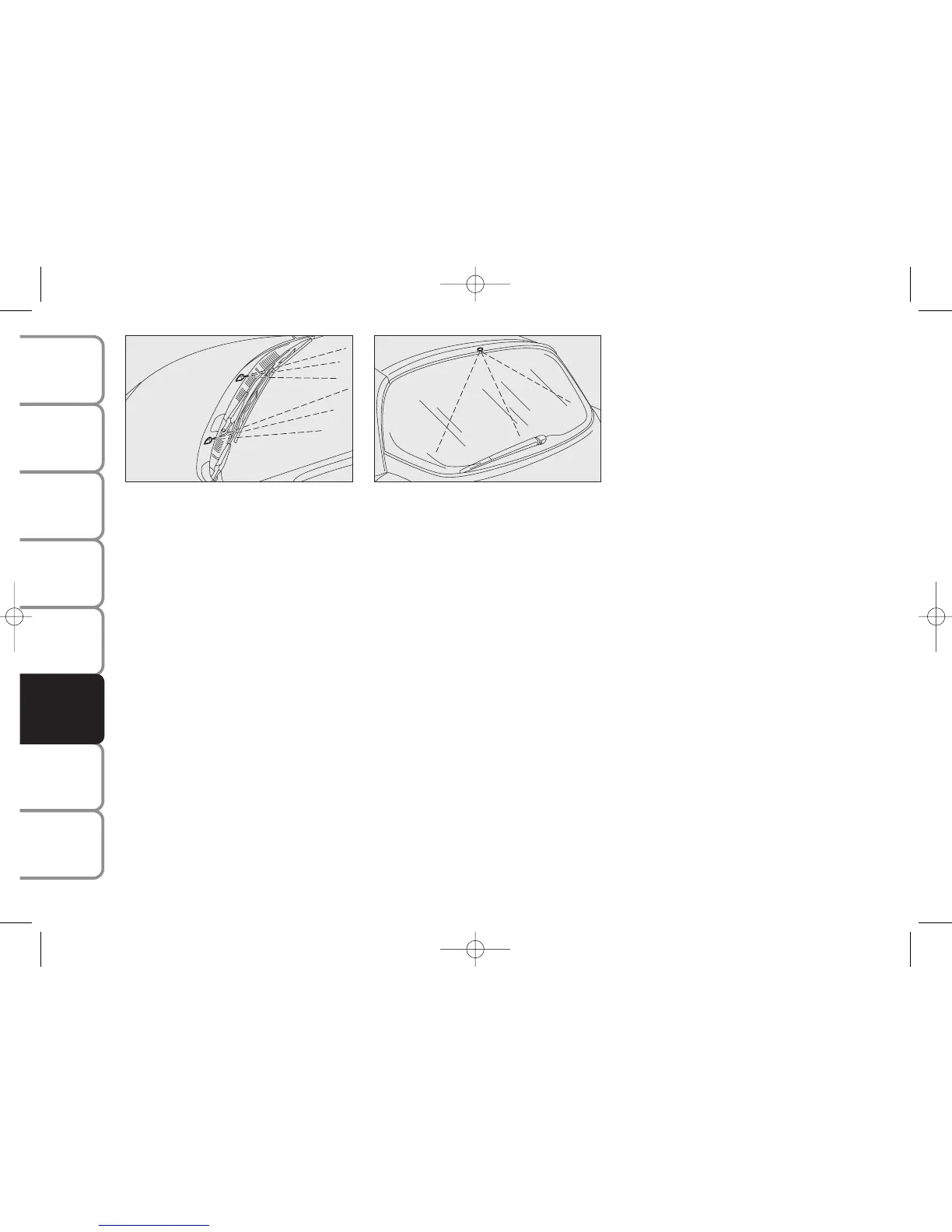

SPRAY NOZZLES

Windscreen washer fig. 8

If the jet of fluid is inadequate, firstly

check that there is fluid in the reservoir:

see “Checking fluid levels” in this

section).

Then check that the nozzle holes are

not clogged, if necessary use a needle.

The windscreen jets are directed by

adjusting the angle of the nozzles.

Fluid jets shall be directed at about

1

/

3

height from the window upper edge.

IMPORTANT On versions with sun-

roof, ensure the roof is closed before

operating the front jets.

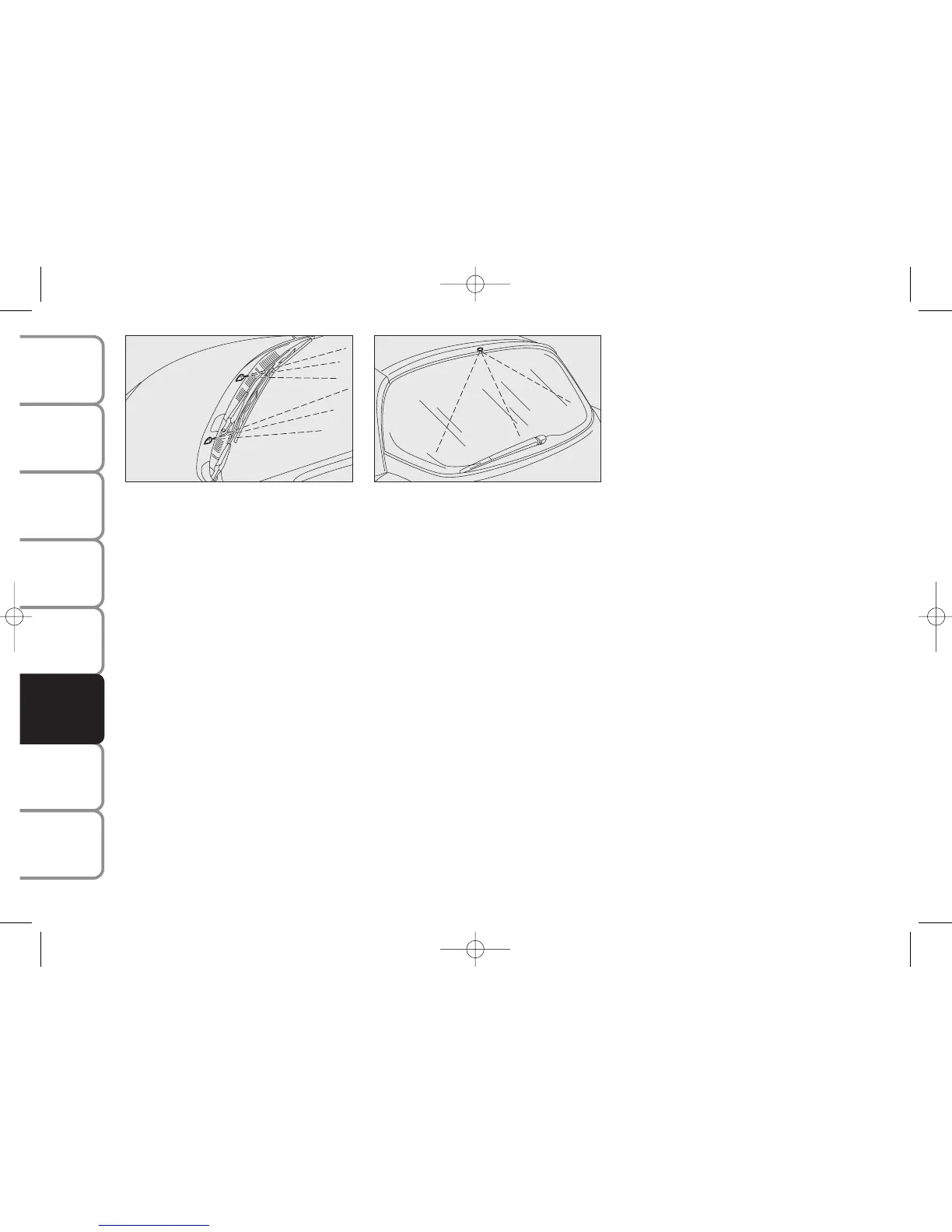

Rear window wiper fig. 9

Rear window washer jets are fixed.

The nozzle holder is on the rear

window.

fig. 8

KA00079m

fig. 9

KA00080m

Loading...

Loading...