Iftheairlterisclogged,ensureitiscleaned:

•

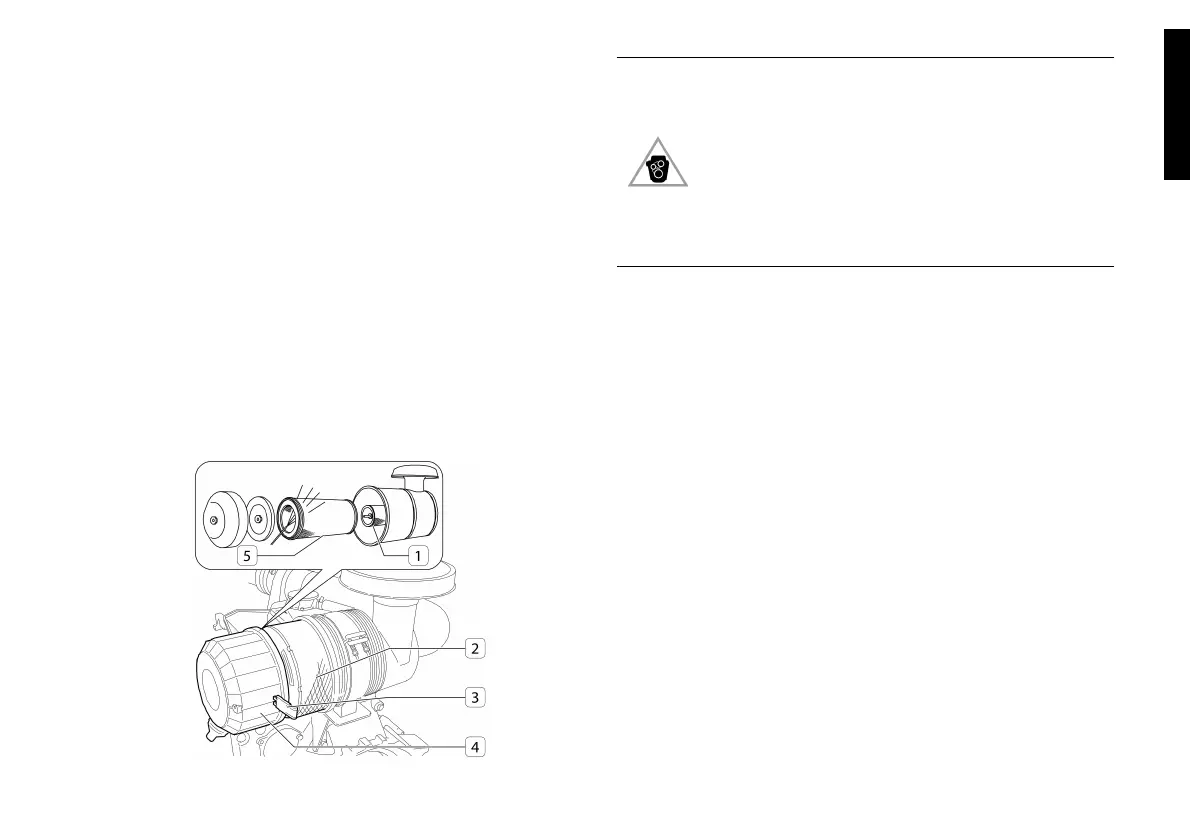

Removetheairltercover(4) (4)

(4)

afterhavingreleasedthetwoquick-clos-

inghooks(3) (3)

(3)

.

•

Removethelter(5) (5)

(5)

.Duringthisoperation,takecaretoensurethatno

dustentersthesleeve.

•

Checktherearenoimpuritiespresent.Ifthereare,cleanthelterele-

mentasindicatedbelow.

•

Blowdehumidiedcompressedaironthelteringelement,working

fromtheinsideout(maximumpressure200 200

200

kPa kPa

kPa

).

•

Checktheconditionoftheairlterbeforerettingit.Replaceifthereis

anysignthatitisbrokenorthereareanytears.

•

Checktheconditionofthegasketatitsbase.

•

Someltersystemsarettedwithasecondlterelement(1) (1)

(1)

which

doesnotrequirecleaning.

•

Positionthelter(5) (5)

(5)

initsseat.

•

Replacethecover(4) (4)

(4)

oftheairlterandlockitinplaceusingthetwo

quickreleasehooks(3) (3)

(3)

.

Riskofdamage

Donotusedetergentsordieseltocleantheairlter.Never

strikethelterelement

withtools.

Makesurethatthepartsarettedcorrectly.Incorrectas-

semblycouldcausetheenginetotakein

unlteredair,causingseriousdamagetotheengine.

Failuretocomplycompletelyorpartiallywiththeserequire-

mentsmayresultintheriskofseriousdamagetotheengine

andmayeven,onoccasion,invalidatethewarranty

For For

For

proper proper

proper

use use

use

of of

of

the the

the

engine engine

engine

•

Beforestartingtheengineeachtime,checkthatthetankcontainsa

sufcientamountoffuel.

•

Avoidprolongingthedurationofthestartcontrol.

•

Followtheindicationsprovidedinthemaintenanceplan.

•

Duringuse,checkperiodicallythat:

○

thetemperatureoftheenginecoolantdoesnotreachthealarm

thresholds;

○

theoilpressureremainswithintheexpectednormalvalues;

•

Thespeedandpowervaluesmustcomplywithindicationsspeciedin

thetechnical-commercialdocumentation.

•

Particularattentionmustbepaidtoenginesthatequiptheemergency

generatorsetsforwhichfrequentefciencychecksarerequiredinorder

toensuretheystartpromptlywheneverrequired.

17

English

Loading...

Loading...