May99/JEB

Page 15 of 16

INSTRUCTION FOR

MAINTENANCE AND REPAIR

FRAMO CARGO PUMP SD100-5

Rev.: A

NB! Framo seal elements installed in impeller and in impeller bolt is made of

a very special material (Elastomeric PTFE, see fig. 5).

These rings must never be mixed with seal rings made of other materials.

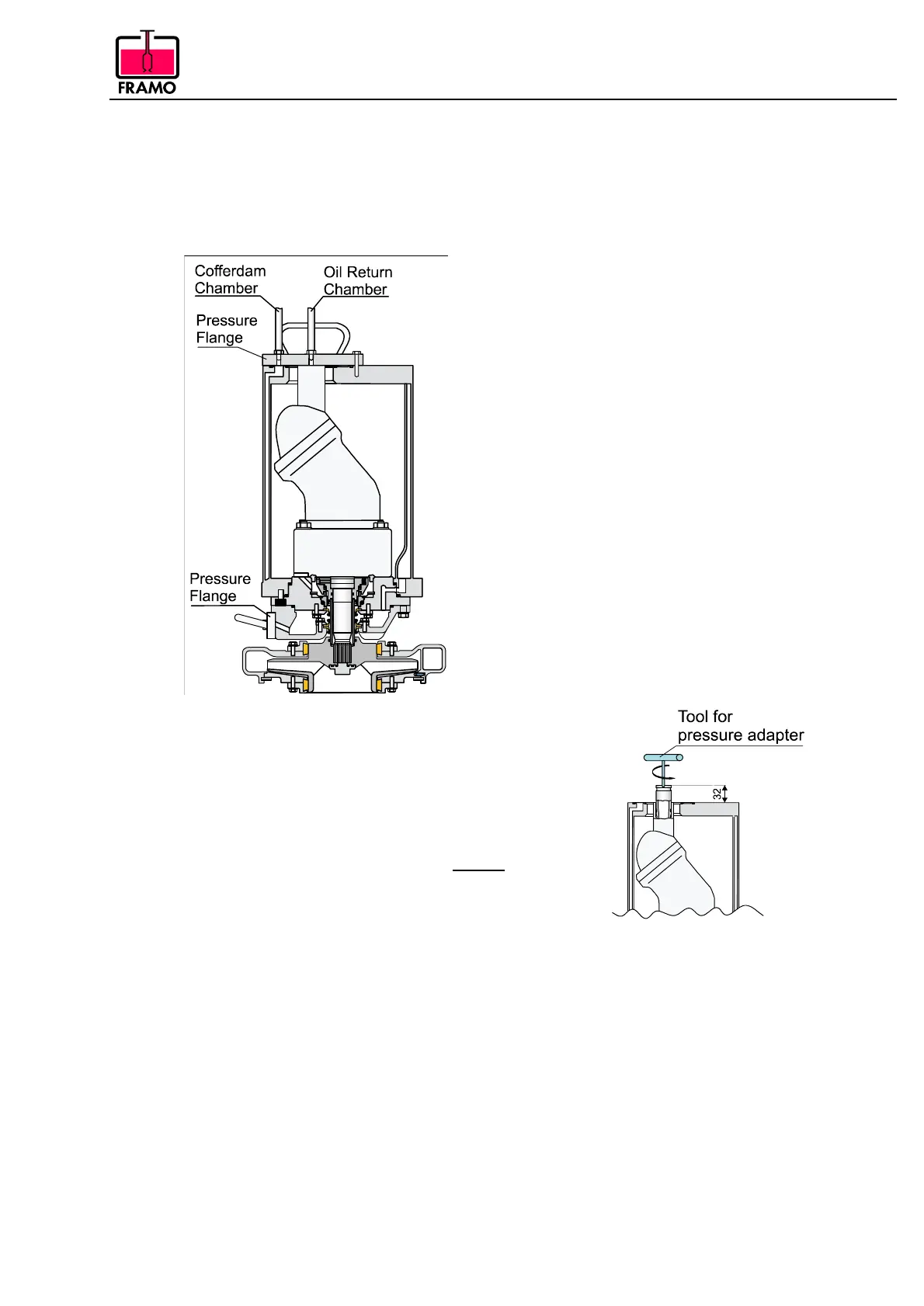

9) After assembling of pump head is

completed, pressure test the pump

head by blinding off the check pipe

connection on lower seal ring house

and assemble pressure flange on

pump casing.

See fig. 18.

Pressure test oil return chamber with

6 bar and cofferdam chamber with

3 bar for 1/2 hour.

No pressure drop is allowed.

Fig. 18

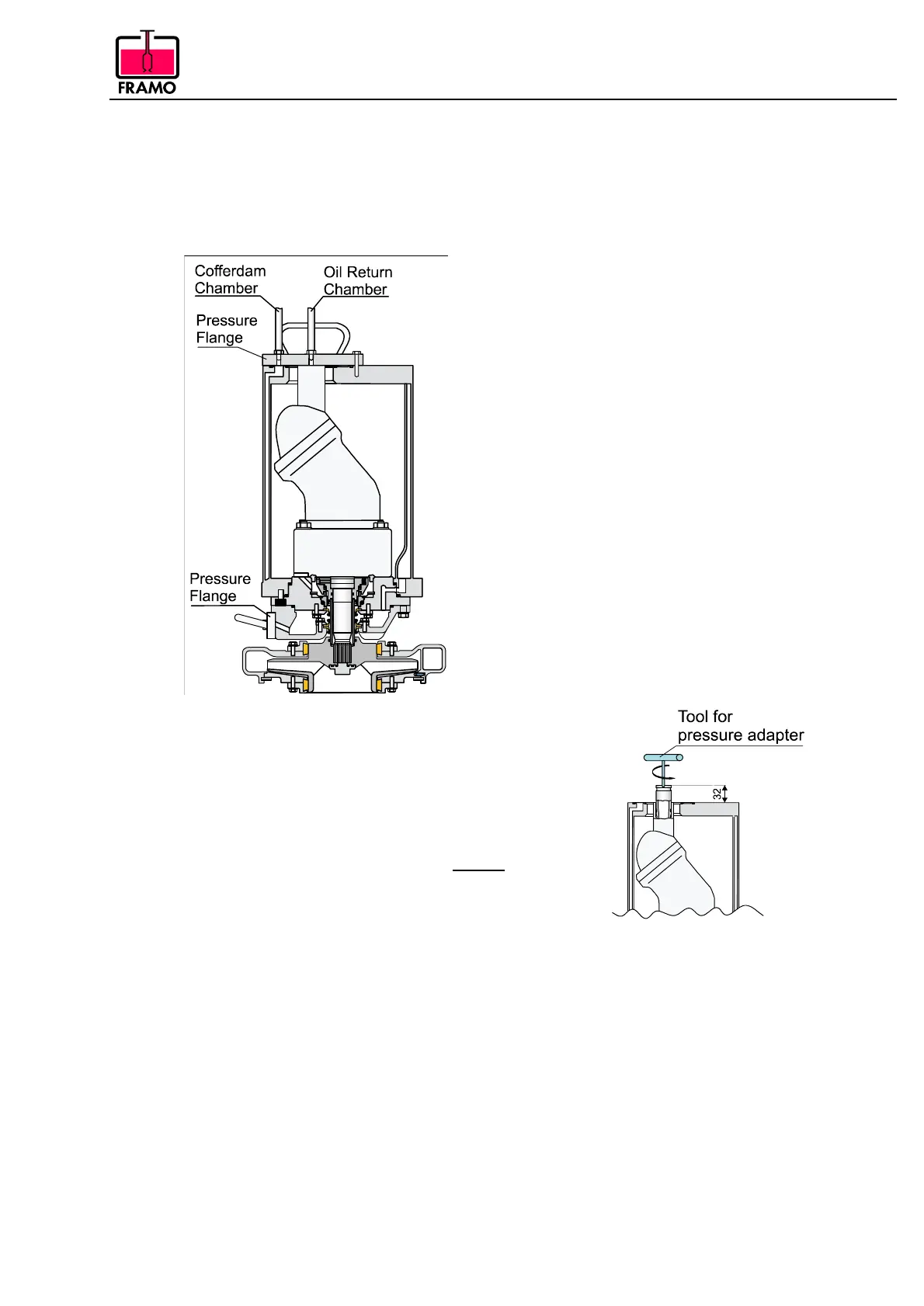

10) Assemble the pressure adapter to

hydr. motor with tool 378-165-3.

See Fig. 19.

The max. height of the adapter is 32 mm.

Fig. 19

11) Check all misalignment according to assembling drawing.

12) Assemble the pump head to pipe stack. Use extractor bolts as shown in fig. 9.

Loading...

Loading...