to short the two magnetic poles and divert

the magnetic field.

5.2 Check the drain plug for metal particles

every 100,000 miles (160 000 km). Clean

away the collected material deposited on

each pole. Magnets will rapidly lose their

effectiveness as collected material

bridges the gap between the two poles.

5.3 Meritor recommends plugs with elements

having a minimum pickup capacity of 1.5

pounds (0.7 kg) of low-carbon steel. Each

time the oil is changed, replace any mag-

netic drain plug that does not meet the

minimum pickup capacity.

5.4 Install the drain plug(s) and tighten to 35

lbf·ft (47 N·m).

6. Fill the axle with recommended lubricant as fol-

lows. For lubricant capacities, see

Table 4

(single axles) or Table 5 (tandem axles). See

Table 3 for recommended lubricant.

6.1 With the vehicle on a level surface, fill the

axle through the oil fill hole. Allow a few

minutes for the oil to flow into the axle.

Lubricant should be level with the bottom

of the oil fill hole.

6.2 Check the fluid level; see

Fig. 4.

6.3 Install and tighten the fill plug 35 lbf·ft (47

N·m).

7. Whenever the interaxle differential housing has

been drained, add an additional 2 pints (0.9 L) of

the recommended lubricant directly into the inter-

axle differential housing.

8. Remove the chocks, then drive the vehicle, un-

loaded, for 1 or 2 miles (2 or 3 km) at speeds

not to exceed 25 mph (40 km/h), to thoroughly

circulate lubricant throughout the carrier and

housing assemblies.

Dana Spicer Axles

NOTE: If using a Roadranger synthetic drive

axle lubricant, the lubricant change interval is

extended to 180,000 miles (288 000 km).

1. Park the vehicle on level ground, set the parking

brakes, and chock the tires.

NOTE: Some Dana Spicer axles have a small

tapped and plugged hole near and below the

housing oil fill hole. This smaller hole is for a

lubricant temperature indicator only, and should

not be used as a fill or level hole.

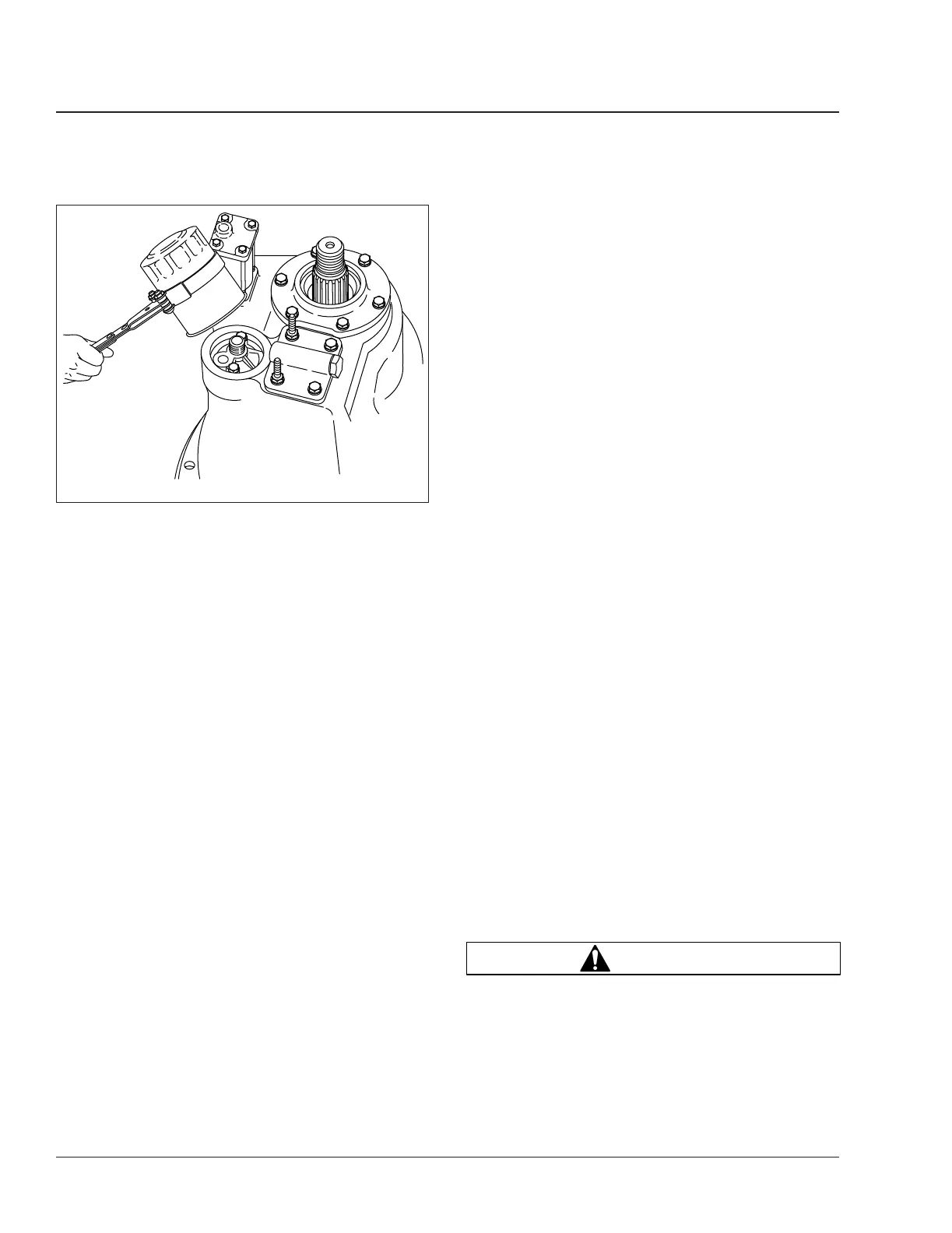

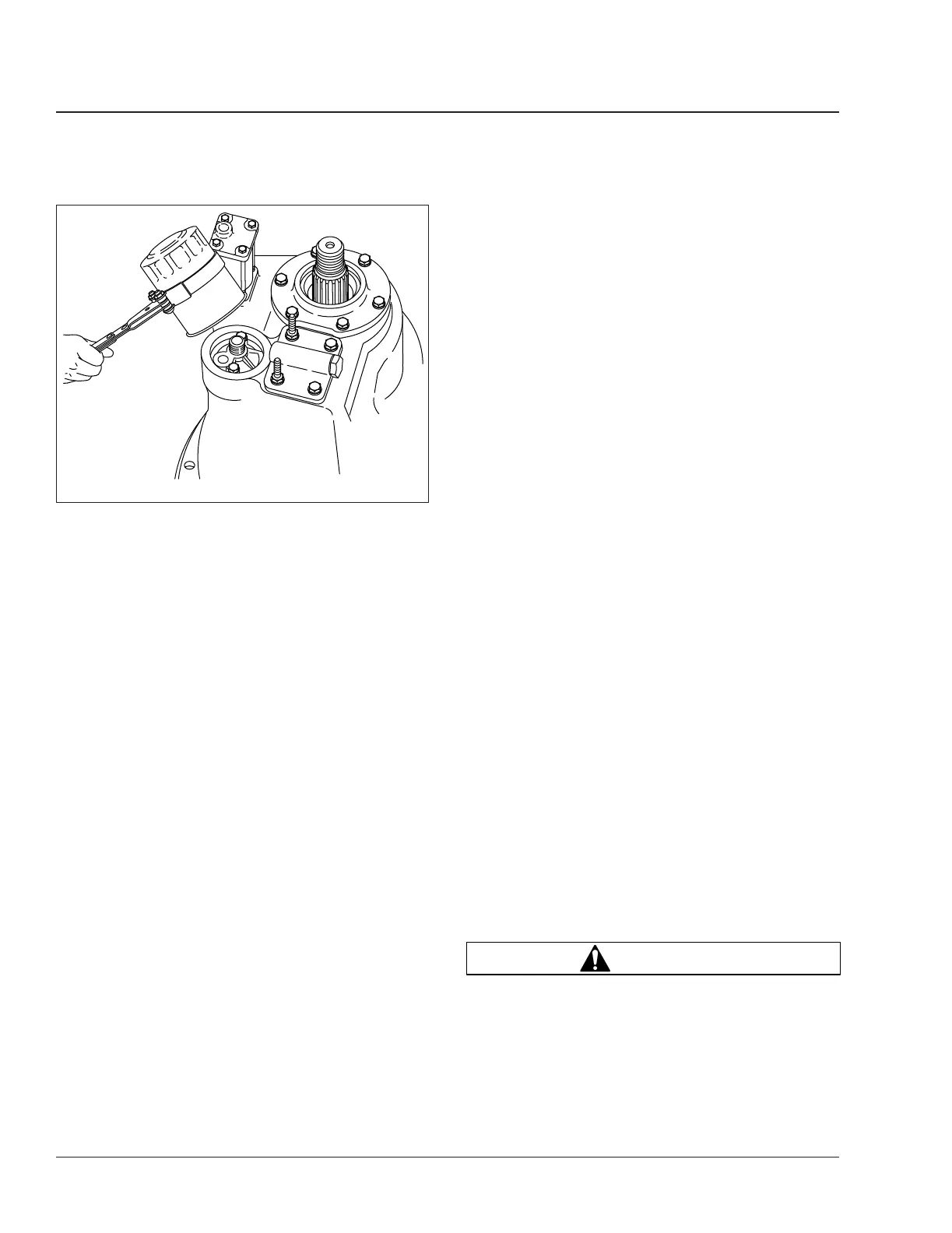

2. Clean the oil fill plug and the area around it (see

Fig. 3), then remove it from the oil fill hole.

3. Place a drain pan under the rear axle drain plug;

see

Fig. 3. Drain the oil at normal operating tem-

perature, 150°F to 200°F (65°C to 93°C). At this

temperature, the oil will run more freely and en-

sure that the axle is flushed.

NOTE: Some tandem-drive axles are equipped

with a cylindrical magnetic strainer, located

below the lube pump on the front of the power

divider cover. All rear axles are fitted with mag-

netic drain and fill plugs.

4. At each axle oil change, remove and clean the

magnetic strainer, if equipped, as follows.

4.1 Remove the magnetic strainer from the

power divider cover. See

Fig. 6.

WARNING

Always wear eye protection when using com-

pressed air to clean parts, as flying debris could

cause permanent damage to unprotected eyes. Do

not point the air stream in the direction of other

persons.

f350119a10/05/2016

Fig. 5, Meritor Axle Oil Filter Removal

Rear Axle35

108SD and 114SD Maintenance Manual, November 201635/6

Loading...

Loading...