41–00 Safety Precautions

Safety Precautions in this section apply to all

procedures within this group.

DANGER

When working on the vehicle, shut down the en-

gine or motor, set the parking brake, and chock

the tires. Before working under the vehicle, always

place jack stands under the frame rails to ensure

the vehicle cannot drop. Failure to follow these

steps could result in serious personal injury or

death.

41–01 Driveline Inspection

1. Park the vehicle on a flat, level surface, apply

the parking brakes, and chock the tires.

WARNING

Self-locking bearing-cup or bearing-strap cap-

screws must not be reused; replace the cap-

screws with new ones. Also, do not undertighten

or overtighten any bearing-cup or bearing-strap

capscrews. A loose or broken fastener at any

point in the driveline weakens the driveline con-

nection, which could cause serious vehicle dam-

age, or could result in a driveshaft separating

from the vehicle, possibly causing loss of vehicle

control that could result in serious personal injury

or death.

2. Check the torque of the U-joint capscrews; see

Table 1 for installed torque values.

Remove and discard any loose capscrews. Do

not reuse any loosened self-locking capscrews;

they are designed for one-time installation only.

Replace all loosened and removed capscrews

with new ones. Tighten the new capscrews as

specified in

Table 1.

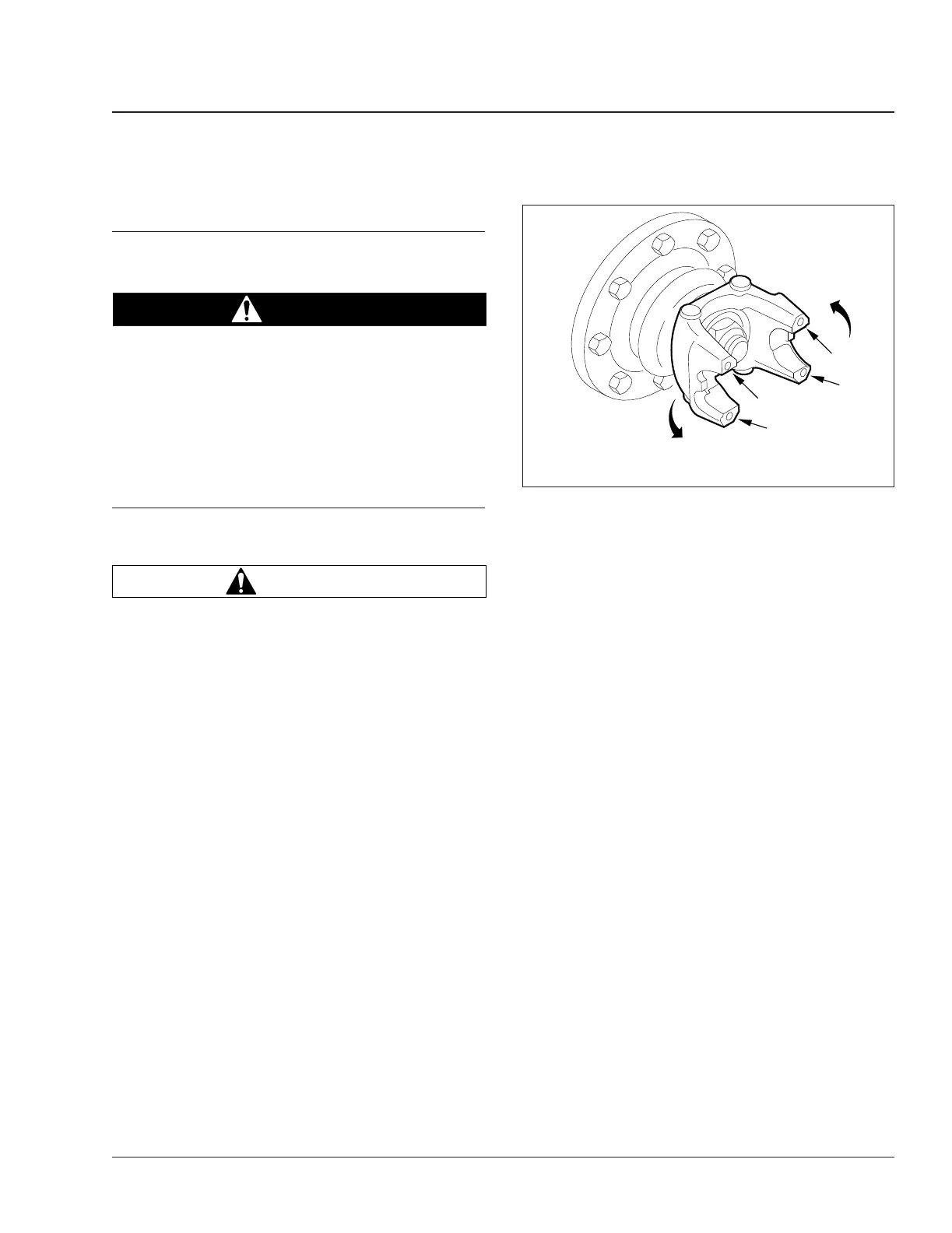

For half-round yokes with bearing straps , tighten

the bearing-strap capscrews following the tight-

ening sequence shown in

Fig. 1, in increments

of 20 lbf·ft (25 N·m) to the torque specifications

listed in

Table 1.

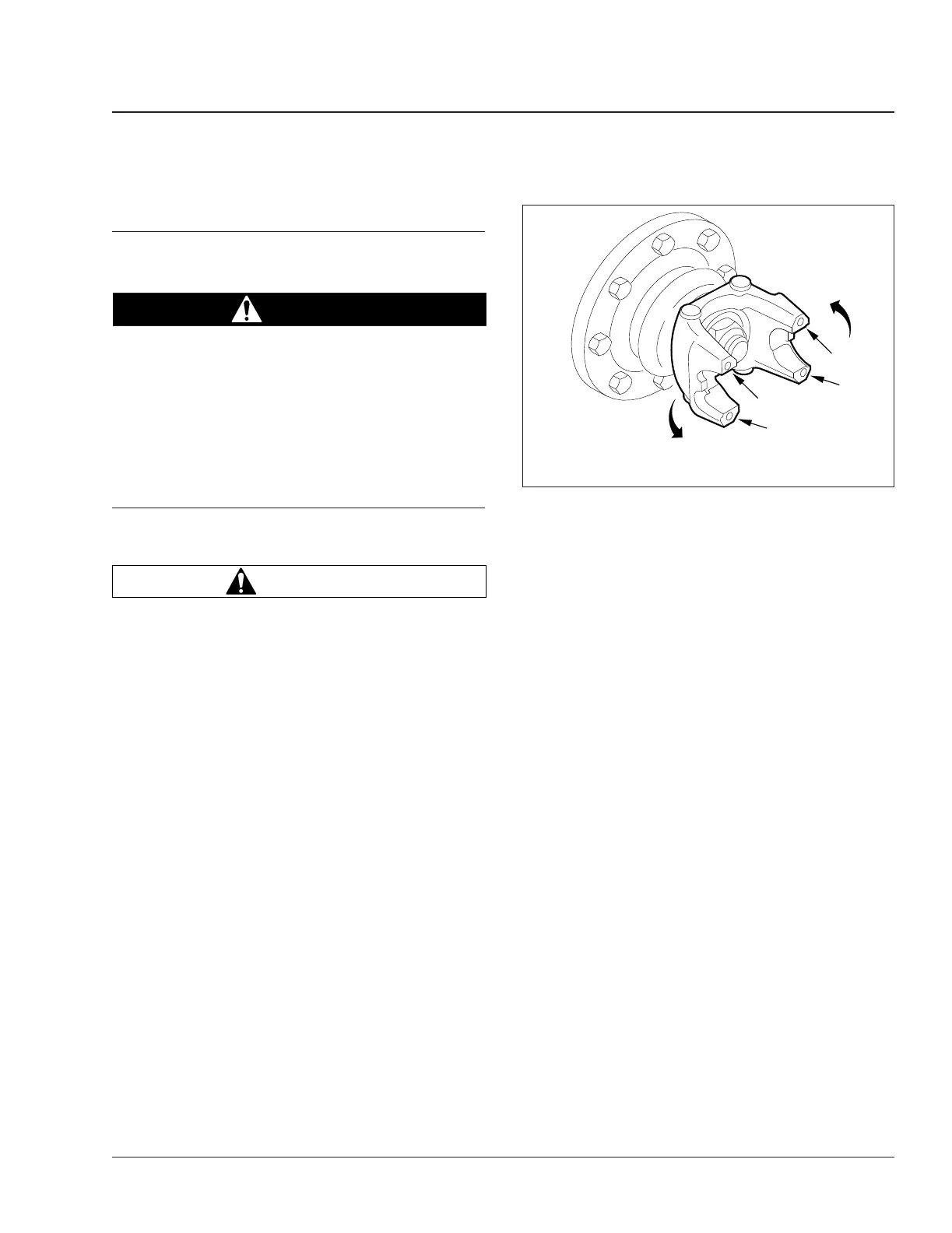

3. Check the driveline yokes for cracks, and check

end-yokes for looseness; see

Fig. 2.

Replace cracked yokes.

If any end-yoke can be moved in or out on its

shaft, or can be rocked on its shaft, disconnect

the driveshaft and U-joint from the yoke, then

check the drive component’s shaft seal for leak-

age or other visible damage that may have been

caused by the loose yoke. Replace the seal if

needed, then tighten the yoke nut. Refer to Sec-

tion 41.00, Specifications 400 of the 108SD

and 114SD Workshop Manual for torque specifi-

cations. If the yoke is still loose after tightening

the yoke nut, replace the end-yoke and yoke nut.

Replace the prevailing torque locknut (end-yoke

nut) if it was removed for yoke replacement, seal

replacement, or any other reason.

4. Check U-joint assemblies for wear by moving the

driveshaft up and down, and from side to side. If

any movement of the U-joint cross in the bear-

ings can be felt or seen, replace the U-joint as-

sembly.

5. Check if the midship bearing and mounting are

loose or have deteriorated, by attempting to

move the driveshaft up and down, and from side

to side. If the bearing is loose on its shaft, or

rattles, replace it. If the bearing mount is loose

on the frame, tighten the mounting fasteners to

the proper torque value. See Section 41.00,

Specifications 400 of the 108SD and 114SD

Workshop Manual for torque specifications. Re-

place the midship bearing assembly if the rubber

cushion is deteriorated or oil-soaked.

12/16/2008 f410529

2

1

2

1

Tighten the capscrews in a counterclockwise sequence,

starting with either number 1 position.

Fig. 1, Tightening Sequence, Half-Round Yoke Bearing

Strap Capscrews

Driveline 41

108SD and 114SD Maintenance Manual, September 2015 41/1

Loading...

Loading...