Group 42 of the 108SD and 114SD Workshop

Manual for repair procedures.

Brake Component Inspection

Air Disc Brakes

IMPORTANT: The following step to inspect the

caliper mounting bolts should only be performed

at the initial maintenance (IM) interval.

Vehicles may have both axial and radial

mounted calipers. Follow the instructions based

on the type of calipers installed on the vehicle.

Axial Mounted Brakes

IMPORTANT: The following information applies

to all types of axial mounted brake applications.

1. Park the vehicle on a level surface, shut down

the engine, and set the parking brake. Chock the

tires.

2. Raise the vehicle and support it on jack stands.

3. Remove all of the wheel assemblies. For instruc-

tions, see Group 40 of the 108SD and 114SD

Workshop Manual.

NOTE: In all steps that require a torque wrench,

use a Snap On torque wrench ATECH4RS600,

or an equivalent, with a center to handle length

of 47 inches (119 cm).

4. Set a torque wrench to 350 lbf·ft (475 N·m) and

tighten the caliper mounting bolts following the

tightening pattern shown in

Fig. 4. If they do not

turn, no further work is needed. If they turn, take

the vehicle to an authorized Freightliner dealer to

have all of the caliper bolts on that wheel end

replaced. Due to limited caliper bolt access, it

may be necessary to use tool DDC DSN-

CHA018005 referenced in tool letter 18TL18.

See

Fig. 5. If the tool is needed, see Table 1 for

torque specifications for a 47 in (119 cm) long

wrench.

f42266503/26/2020

12 4 5

3 6

Fig. 4, Axial Bolt Tightening Pattern

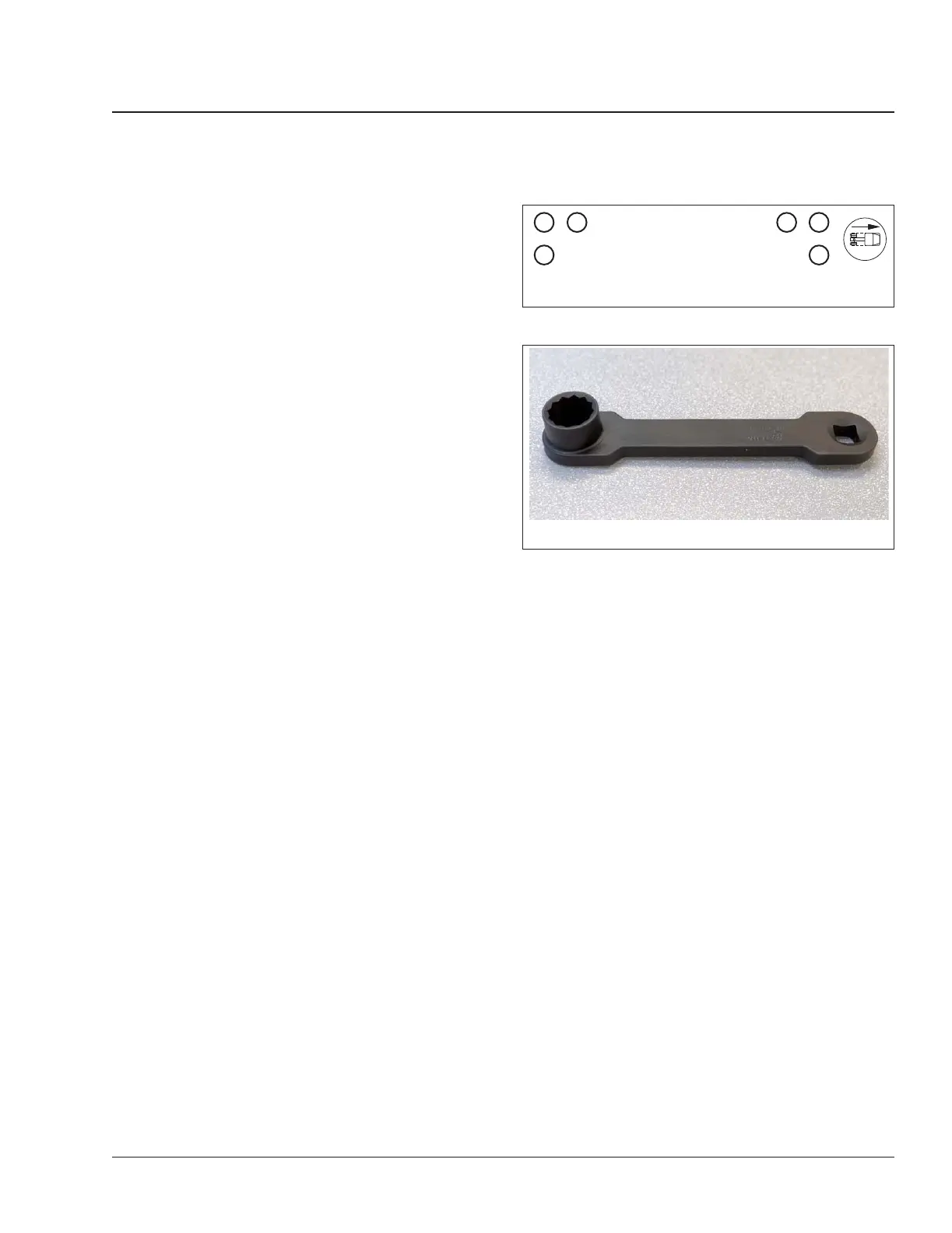

f58051809/28/2018

Fig. 5, DDC DSNCHA018005 30mm Air Disc Brake

Caliper Brake Bolt Torque Adaptor

Brakes 42

108SD and 114SD Maintenance Manual, October 2019 42/7

Loading...

Loading...