on the frontwall. The sensors are located in high

areas, where rising gas vapors will pass by or ac-

cumulate. Do not use a high-pressure washer,

steam cleaner, or silicone-based chemicals on the

gas detection sensors, as this may permanently

disable the sensors. When cleaning the vehicle,

cover the sensors with a plastic covering. Keep

the sensors covered until the area has been

cleared of any cleaning fumes. Harsh chemicals

and extremely high temperatures may damage the

sensor.

Use a bubble solution to check for leaks while per-

forming the following inspection.

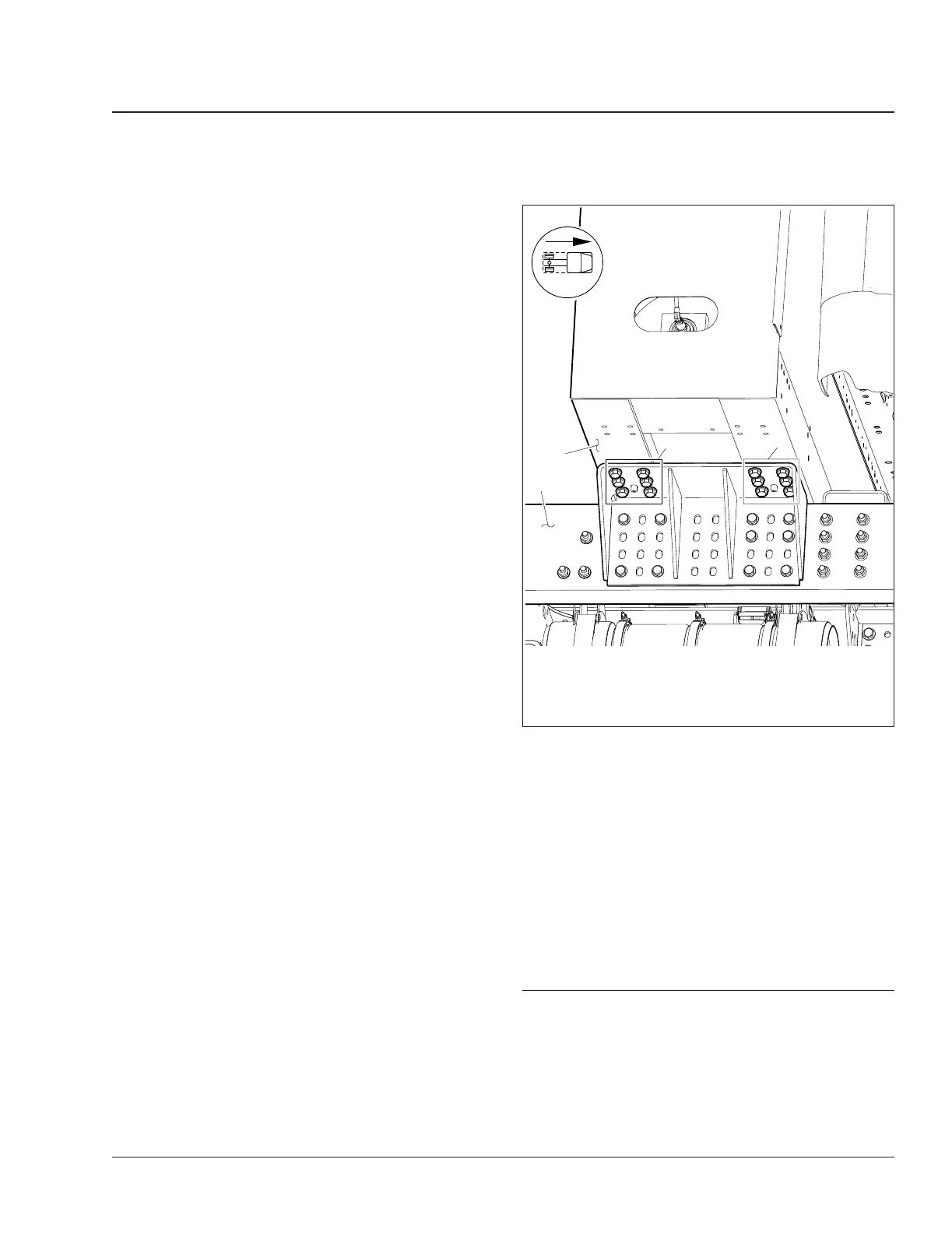

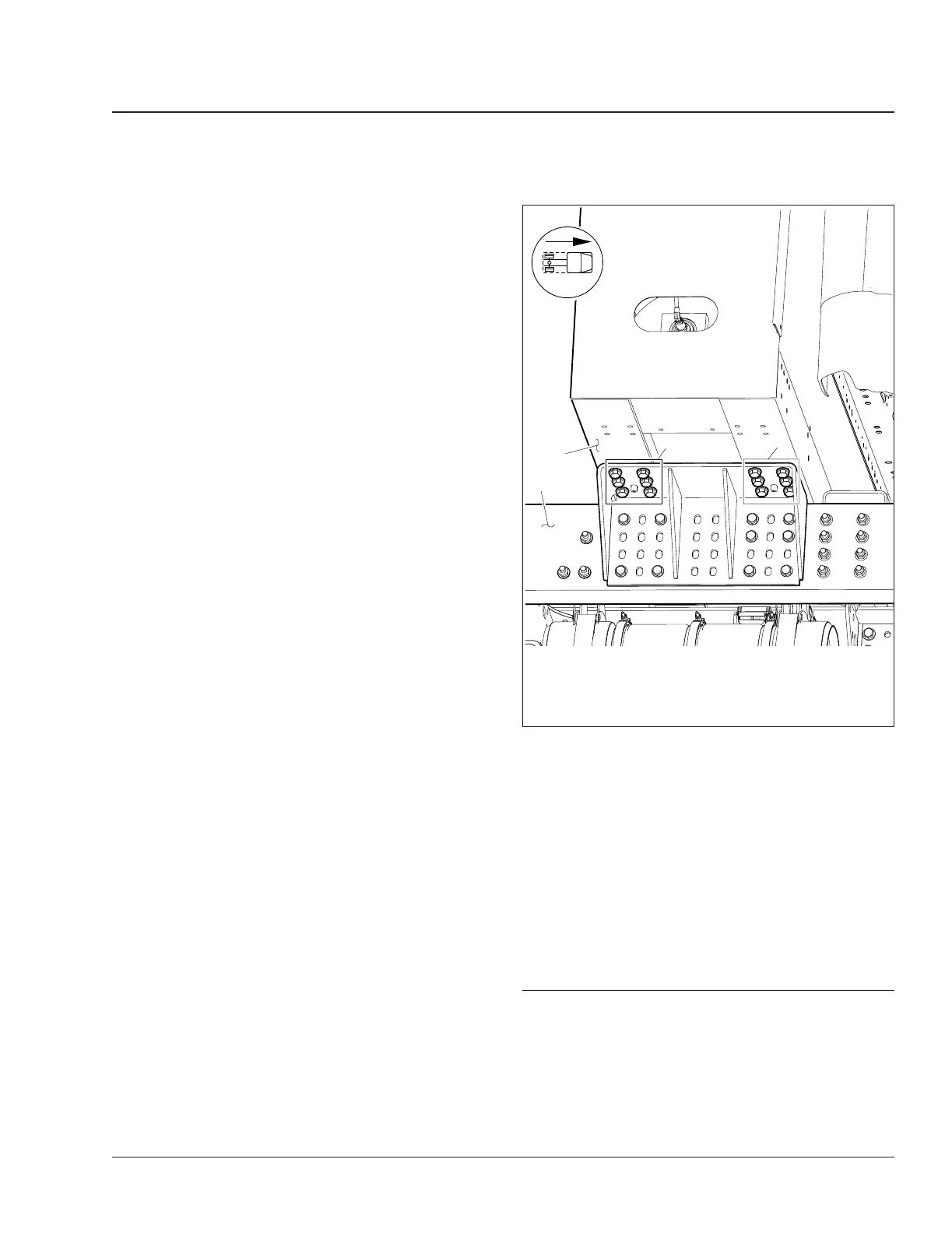

1. Inspect the fuel cylinders for dents or other signs

of damage.

Replace any leaking fuel cylinders.

2. Ensure that the fuel cylinders are secured within

the fuel cylinder storage box.

3. Ensure that the fuel cylinder storage box is se-

cured to the frame. Inspect for any signs of

looseness. If necessary, tighten the storage box

mounting bolts 160 lbf·ft (217 N·m). See

Fig. 11.

NOTE: During initial pre-delivery inspection

(PDI), tighten the storage box mounting bolts

(shown in

Fig. 11) 180 lbf·ft (244 N·m).

4. Inspect the fuel fill port for signs of damage or

leaks. Ensure the port dust cover and the O-ring

inside the port are both present and in good con-

dition. See

Fig. 12.

5. Inspect the pressure gauges on the fuel box for

cracks. Ensure the indicator needles are present

and in working condition. Inspect the gauge

faces for accuracy and legibility.

6. Ensure blue caps are present on all pressure

relief devices. Each fuel cylinder is equipped with

two caps (one on each end), which are visible on

the back of the CNG fuel cylinder storage box.

One cap is located on the pressure relief valve

on the inboard side of the CNG fuel box, next to

the fuel outlet line. Check the primary relief valve

on the inboard side of the CNG fuel box for signs

of damage or leaks.

7. Check the following components for signs of

damage or leaks:

• manual fuel shutoff valve

• fuel cylinder shutoff valves (see

Fig. 13)

• coolant hoses and fittings

• fuel lines and fittings

• all fittings, connections, and joints

8. Replace leaking or damaged fuel lines. Repair or

replace leaking or damaged fittings.

47–07 CNG High-Pressure Fuel

Filter Element

Replacement

CNG filter element replacement cycles are an impor-

tant factor in maintaining the CNG fuel system integ-

rity and ensuring maximum operating performance.

Actual frequency of the filter element replacement

05/04/2010 f470555

1

2

33

1. Frame Rail

2. CNG Fuel Cylinder Storage Box

3. Mounting Bolts (qty 12 per side)

Fig. 11, Fuel Cylinder Storage Box Mounting Bracket

(passenger side shown)

Fuel 47

108SD and 114SD Maintenance Manual, May 2018 47/11

Loading...

Loading...