9.4 The outboard slider assembly requires no

adjustment. If the plungers are loose, in-

spect and replace locking mechanism

parts as needed.

9.5 The inboard slider is adjustable for frame

width and plunger engagement. For ad-

justment, refer to the fifth wheel installa-

tion instructions.

10. Replace cracked, worn, or damaged parts with

new parts. Replace all loose mounting bolts with

5/8–11 SAE grade 8 bolts, grade C locknuts, and

hardened washers. Do not re-use bolts, nuts,

and washers on fifth wheel mountings.

11. After inspecting the fifth wheel, lubricate all mov-

ing parts with a chassis or multipurpose grease.

Apply a generous coating of grease to the top

plate to fill the grooves, or depressions, on the

top plate. See

MOP 31–03 for lubrication instruc-

tions.

31–03 Fifth Wheel Lubrication

To maintain proper fifth wheel operation, always lubri-

cate the fifth wheel after an inspection has been

performed.

IMPORTANT: Lubricate the fifth wheel:

• After power washing, or steam cleaning.

• If the vehicle operates in harsh conditions such

as salt spray from road surfaces, or in ex-

tremely dusty environments.

• After any service that requires removal of lubri-

cation from the fifth wheel top plate or compo-

nents.

WARNING

Failure to properly lubricate the fifth wheel could

result in a possible disengagement of the trailer

from the tractor, which could result in personal

injury or property damage.

Fontaine

1. Tilt the top plate forward (the front of the fifth

wheel is down) and apply grease to each bearing

area through the zerk fittings located on each

side of the top plate just to the front of the

bracket pins. Continue to apply grease until it is

coming out of the back of the bearing. It may be

necessary to raise the rear of the fifth wheel with

a pry bar to open up the pocket slightly and

allow the grease to flow through. A substantial

amount of grease may be required initially to fill

the reservoir.

Tilt the fifth wheel ramps down (the rear of the

fifth wheel is down) and repeat the greasing pro-

cedure. Rock the top plate back and forth sev-

eral times to spread the grease over the bearing

surface.

2. Inspect the trailer kingpin plate and top surface

of the fifth wheel to make sure each is properly

greased. A liberal coating of grease should be

applied to the complete surfaces of both the

trailer kingpin plate and the top surface of the

fifth wheel.

09/02/2009

3

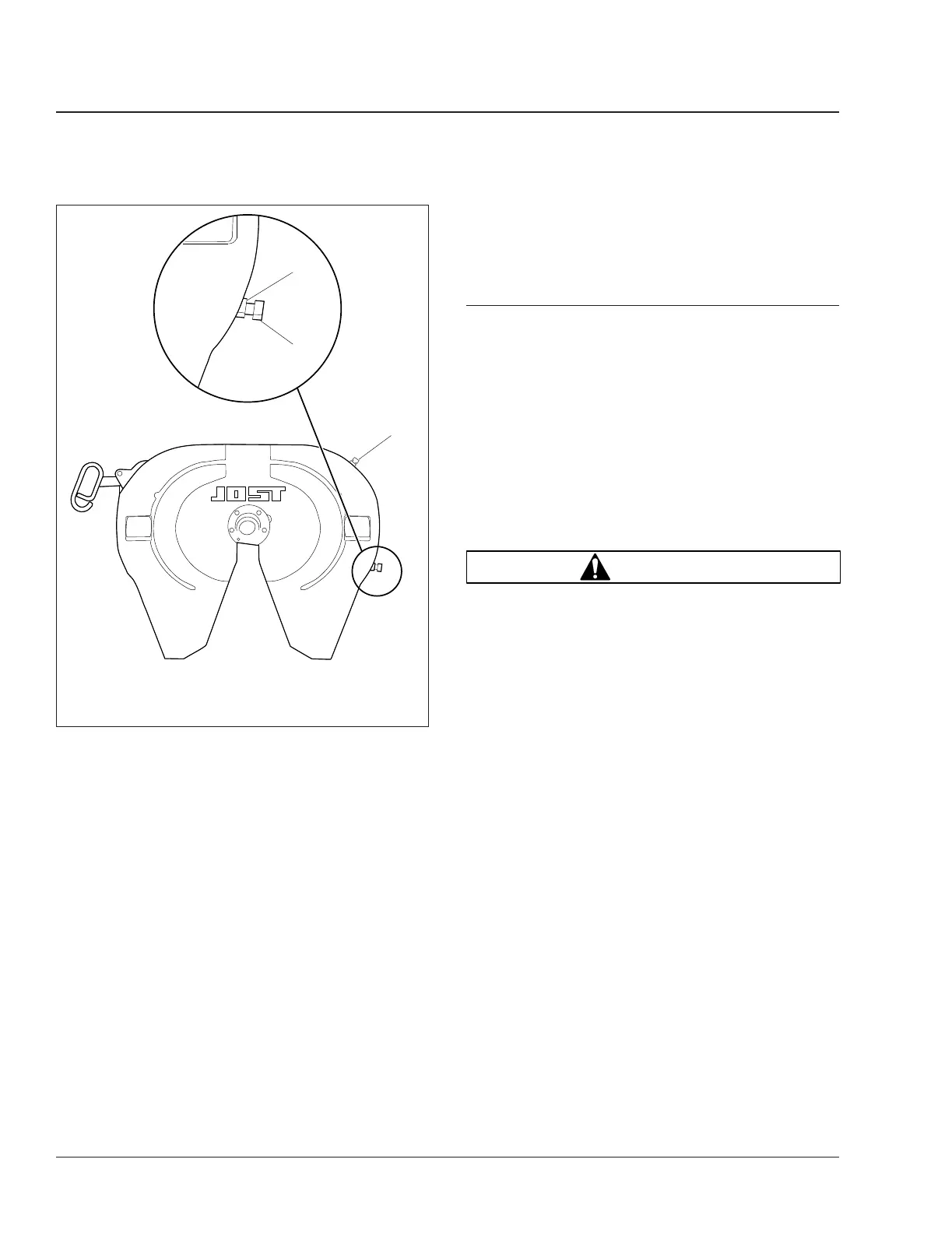

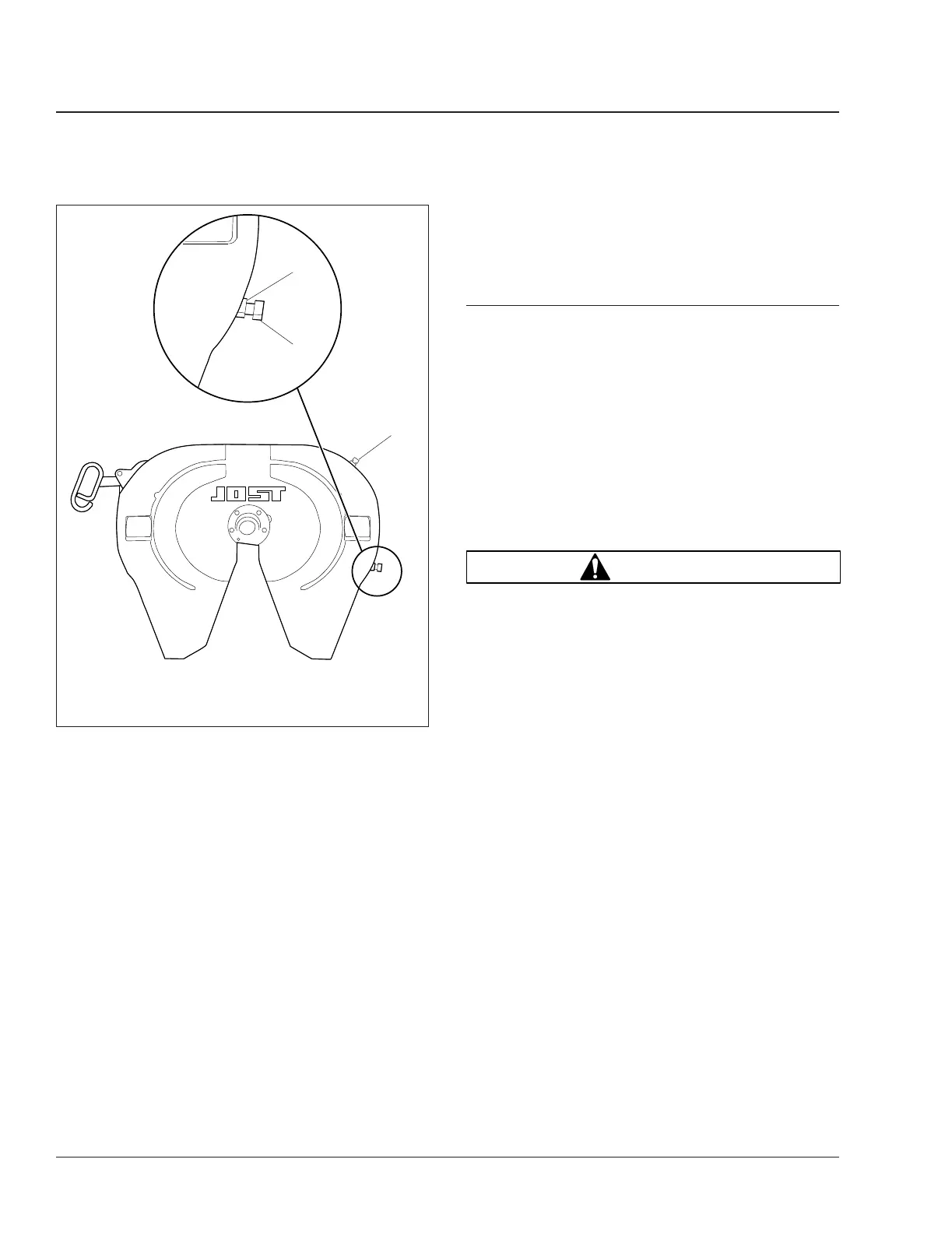

1

2

f311100

1. Jam Nut

2. Adjustment Bolt

3. Grease Zerk

Fig. 7, Jost Fifth Wheel

Frame and Frame Components31

108SD and 114SD Maintenance Manual, May 201831/6

Loading...

Loading...