4. Inspect the weld seams between the torque arm

tube and the shorter bushing tubes. If there are

cracks, replace the torque arm. Do not weld the

torque arm for any reason.

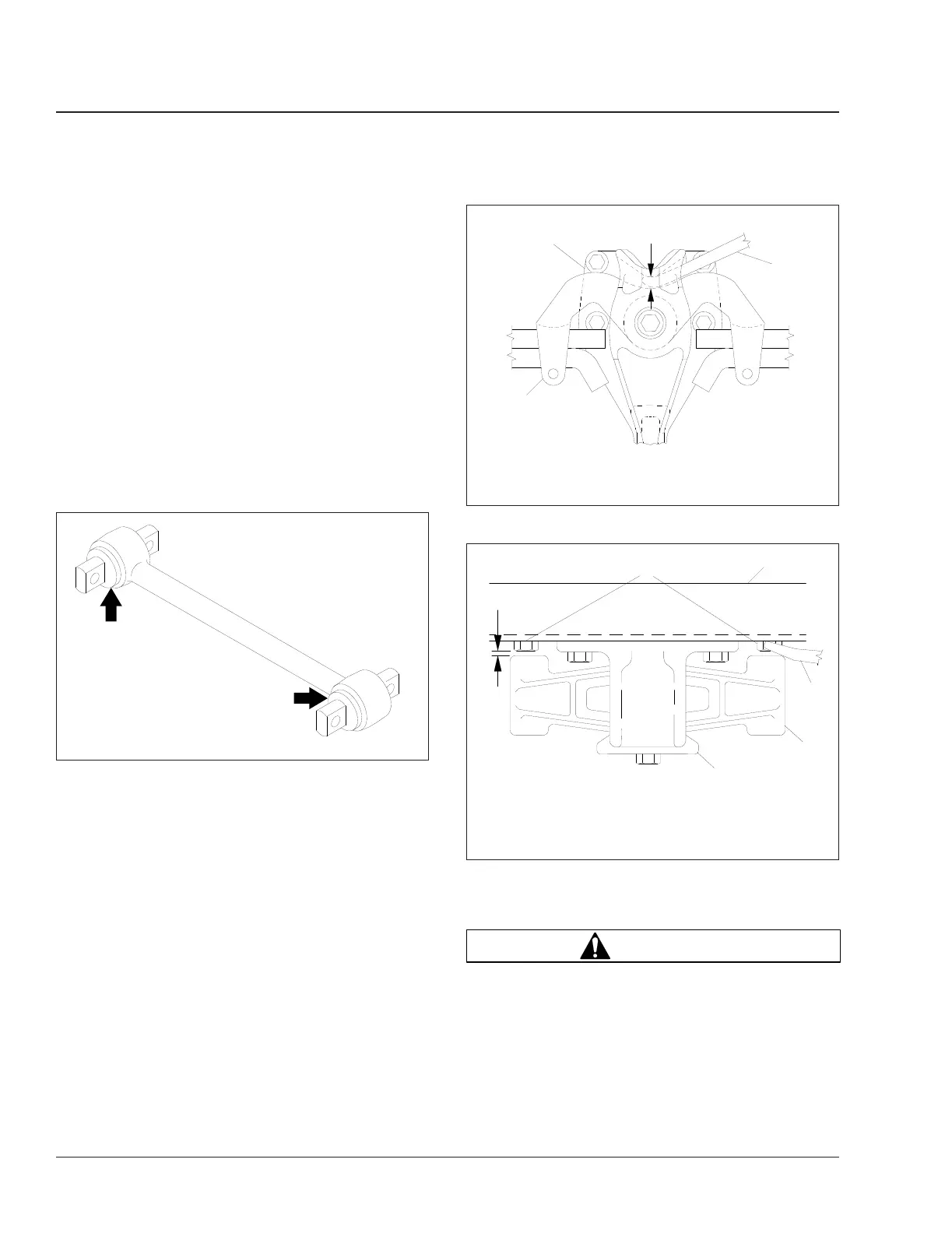

5. Inspect the rubber bushing ends. See

Fig. 1. Re-

place the torque arm for any of the following rea-

sons:

• if there are gaps between the rubber bush-

ing and the pin or outer steel sleeve;

• if either bushing end contacts a torque arm

pin mounting bolt;

• if there are cracks in the bushing;

• if part of the rubber bushing extends be-

yond the outer circumference of the outer

bushing sleeve.

6. Block up the frame enough to take chassis

weight off the springs. Attempt to move the

equalizer up and down, using a pry bar between

the top of the equalizer and top of the equalizer

bracket; apply hand pressure only. See

Fig. 2.If

movement at the center of the equalizer exceeds

1/8 inch (3 mm), replace the equalizer bushings.

See Group 32 of the 108SD and 114SD Work-

shop Manual for instructions.

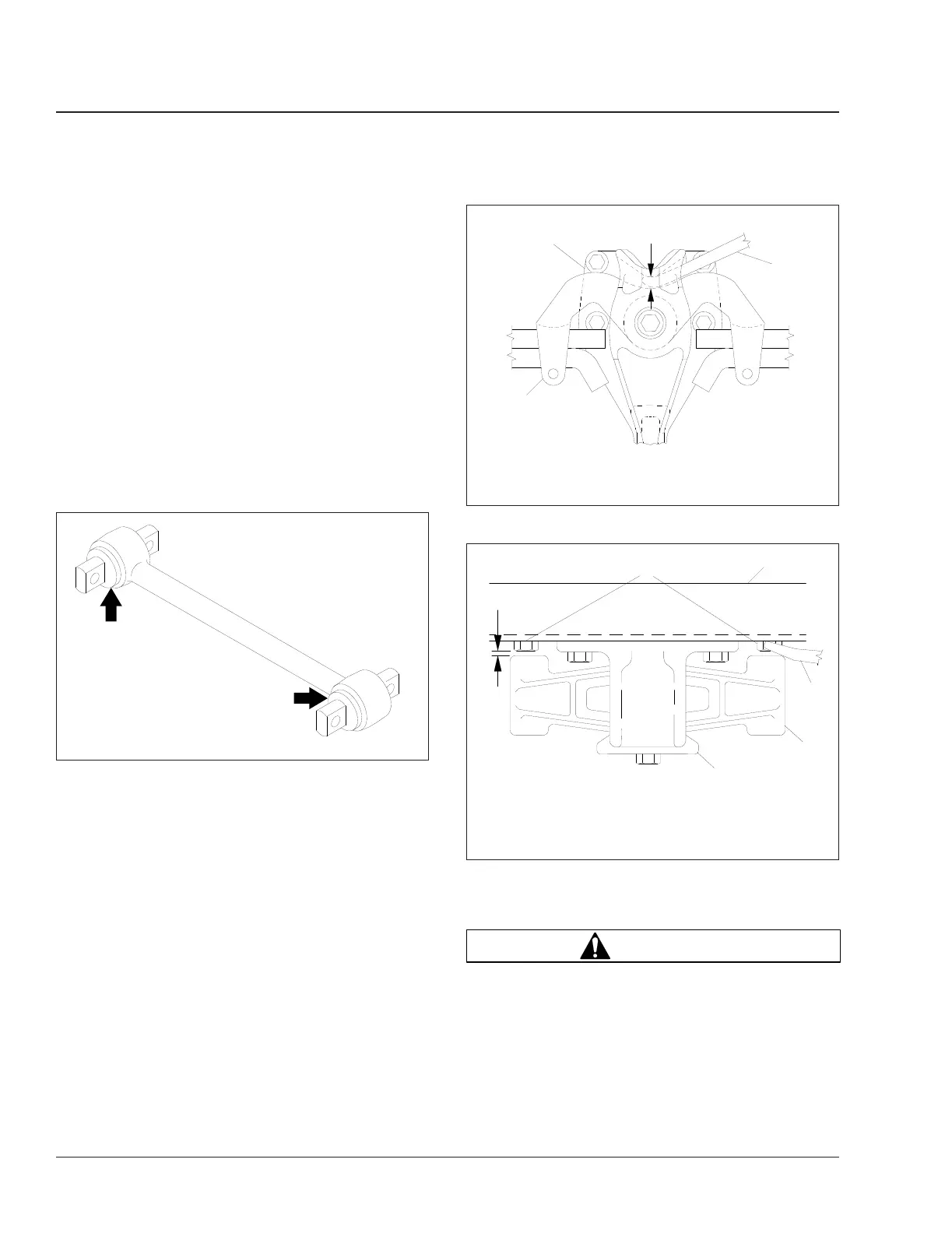

7. With the vehicle unloaded, attempt to move the

equalizer side to side, using a pry bar between

the equalizer and frame rail. Apply hand pressure

only. See

Fig. 3. If clearance between the equal-

izer assembly and any frame component or fas-

tener is less than 1/8 inch (3 mm), replace the

equalizer bushings. See Group 32 of the 108SD

and 114SD Workshop Manual for instructions.

Freightliner AirLiner Suspension

WARNING

Do not replace individual leaves of a damaged leaf

spring assembly; replace the complete spring as-

sembly. Visible damage (cracks or breaks) to one

leaf causes hidden damage to other leaves. Re-

placement of only the visibly damaged part(s) is

no assurance that the spring is safe. On front

spring assemblies, if cracks or breaks exist in the

f320021a

05/27/93

Fig. 1, Torque Arm Bushings

f320022a

05/27/93

1

2

3

A

A. Measure the change in gap at this point.

1. Equalizer Bracket

2. Equalizer

3. Pry Bar

Fig. 2, Side View of the Equalizer

f320023a

05/27/93

1

2

3

4

5

A

A. 1/8" (3 mm) Clearance

1. Frame Fasteners

2. Frame Rail

3. Pry Bar

4. Equalizer

5. Equalizer Bracket

Fig. 3, Top View of the Equalizer

Suspension32

108SD and 114SD Maintenance Manual, September 201532/2

Loading...

Loading...