NOTICE

To prevent voiding the warranty on Barksdale

height-control valves, observe the following:

• When removing or loosening a Barksdale

height-control valve from a mounting bracket,

always hold the valve-side mounting studs in

place with an Allen wrench while loosening or

tightening the nuts that attach the valve to the

bracket. Because the mounting studs are

threaded into the valve body, loosening the nuts

without holding the studs can tighten the studs,

which can crush the valve body and damage

the valve. Conversely, tightening the nuts with-

out holding the studs can back the studs out,

causing a separation of the two halves of the

valve body, and possibly a leak.

• Do not overtighten the bolts in the Barksdale

height-control valve housing. The bolts should

not be loose, and should not require tightening.

Only if necessary, tighten the valve housing

bolts 45 lbf·in (500 N·cm). Any damage to the

valve housing will void the warranty.

• Do not attempt to disassemble the Barksdale

valve body or the control lever. There are no

serviceable parts in the valve, and any disas-

sembly will void the warranty.

1. Park the vehicle on a level surface, using a light

application of the brakes. Do not apply the park-

ing brakes. Shift the transmission into neutral,

and build the secondary air pressure to at least

100 psi (690 kPa). Shut down the engine.

2. Mark the location of the front and rear tires on

the floor, and chock the tires on one axle only.

3. Check that the height-control valve vertical link-

age is connected and oriented correctly.

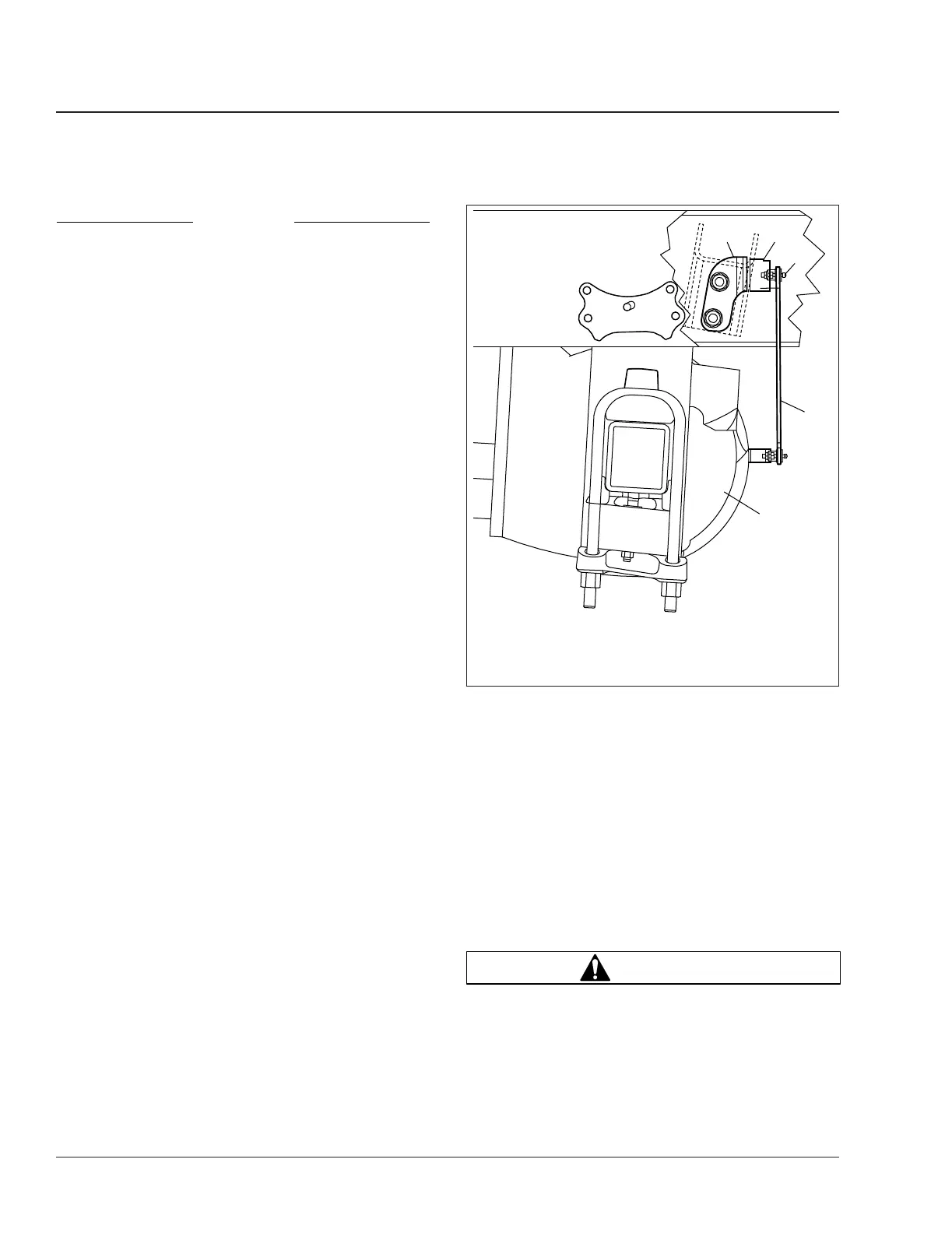

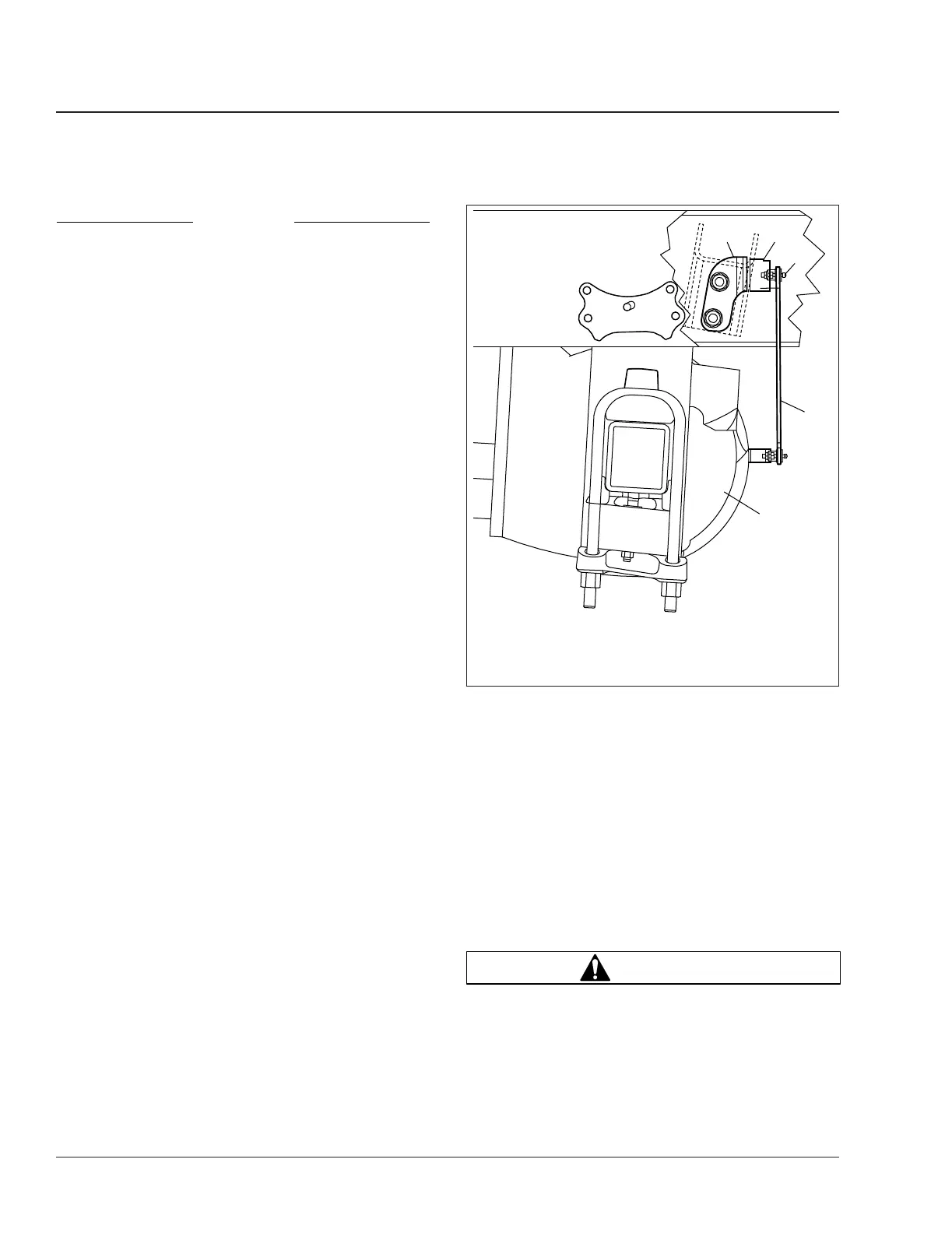

NOTE: The stud bolt that fastens the height-

control valve horizontal lever to the vertical link-

age is oriented correctly when the linkage rod is

vertical, as viewed from the side of the vehicle;

see

Fig. 4. The rod may be on the forward or

aft side of the lever to get it to be vertical.

4. Measure the distance from the axle stop to the

top of the axle U-bolt pad. The correct distance

is determined by the axle and suspension con-

figurations; refer to Group 32 of the 108SD and

114SD Workshop Manual for details.

5. If the axle stop measurement is not correct, see

Group 32 of the 108SD and 114SD Workshop

Manual for adjustment procedures.

6. Apply the parking brakes, and remove the

chocks.

Freightliner TufTrac

1. Inspect the suspension spring assemblies for

pitted, cracked, broken, or abnormally bent

leaves, and extreme rust. If any of these condi-

tions exist, replace the spring assembly.

WARNING

Do not replace individual leaves of a damaged leaf

spring assembly; replace the complete spring as-

sembly. Visible damage (cracks or breaks) to one

leaf causes hidden damage to other leaves. Re-

placement of only the visibly damaged part(s) is

no assurance that the spring is safe. On front

f320562a10/05/2016

1

2

3

4

5

1. Valve Mounting

Bracket

2. Height-Control Valve

3. Stud Bolt

4. Linkage Rod

5. Axle

Fig. 4, Typical Barksdale Height-Control Valve

Installation (side view)

Suspension32

108SD and 114SD Maintenance Manual, September 201532/4

Loading...

Loading...