7.3 Install the fifth wheel top plate, bushing

pins, and roll pins.

8. Inspect for fatigue or cracked welds.

9. Replace cracked, worn, or damaged parts with

new parts. Replace all loose mounting bolts with

5/8–11 SAE grade 8 bolts, grade C locknuts, and

hardened washers.

Do not

re-use bolts, nuts,

and washers on fifth wheel mountings.

10. After inspecting the fifth wheel, lubricate all mov-

ing parts with a chassis or multipurpose grease.

See Maintenance Operation 31–02 for lubrica-

tion instructions.

Castloc II and Simplex Series

1. Disconnect the tractor from the trailer. For in-

structions, see the vehicle driver’s manual.

2. Thoroughly steam clean the fifth wheel.

3. Check the fifth wheel plate for cracks. Check for

sharp edges on top; the chamfer should be 1/8

to 1/4 inch (3 to 6 mm).

4. When the wheel is locked, the safety latch must

swing free and fall freely into position. See

Fig. 3.

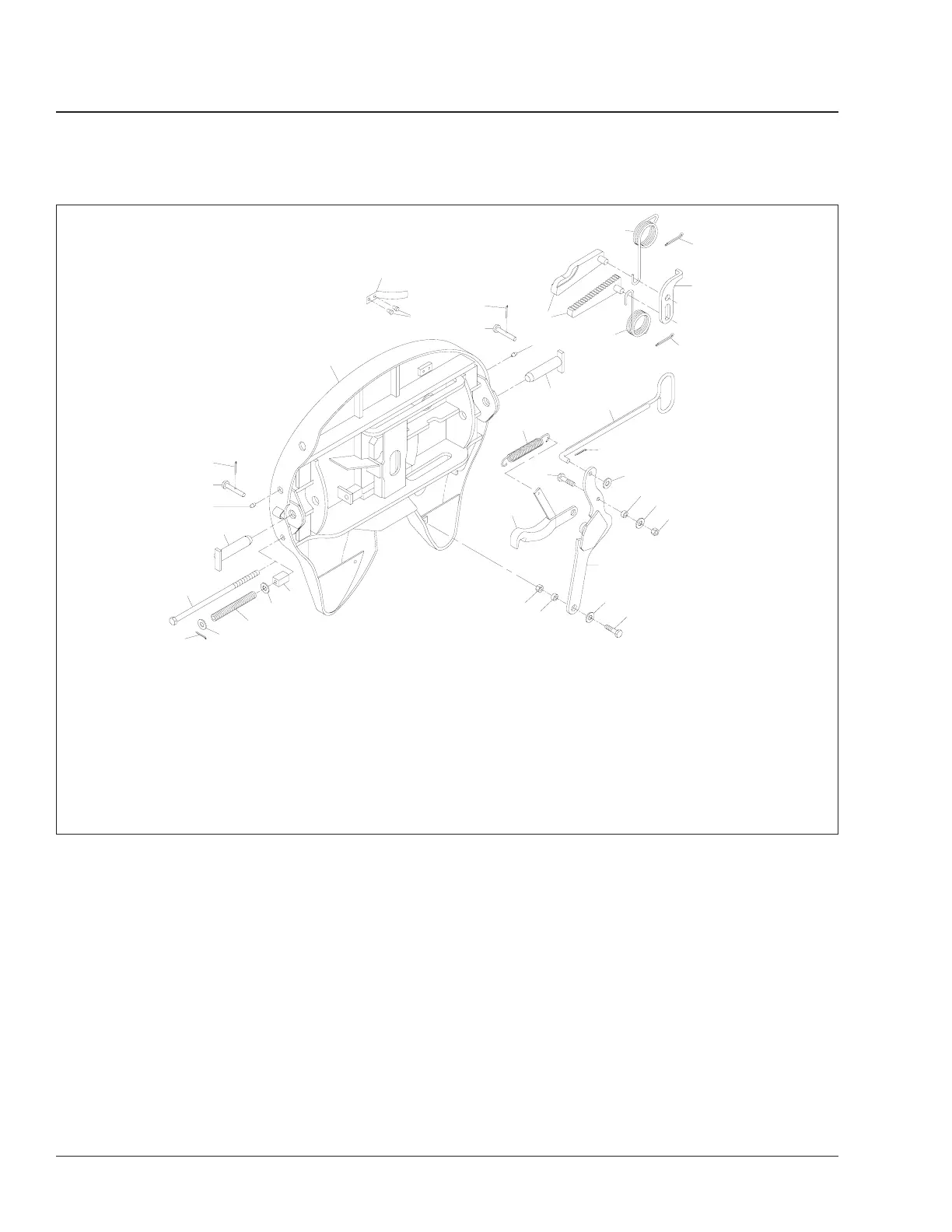

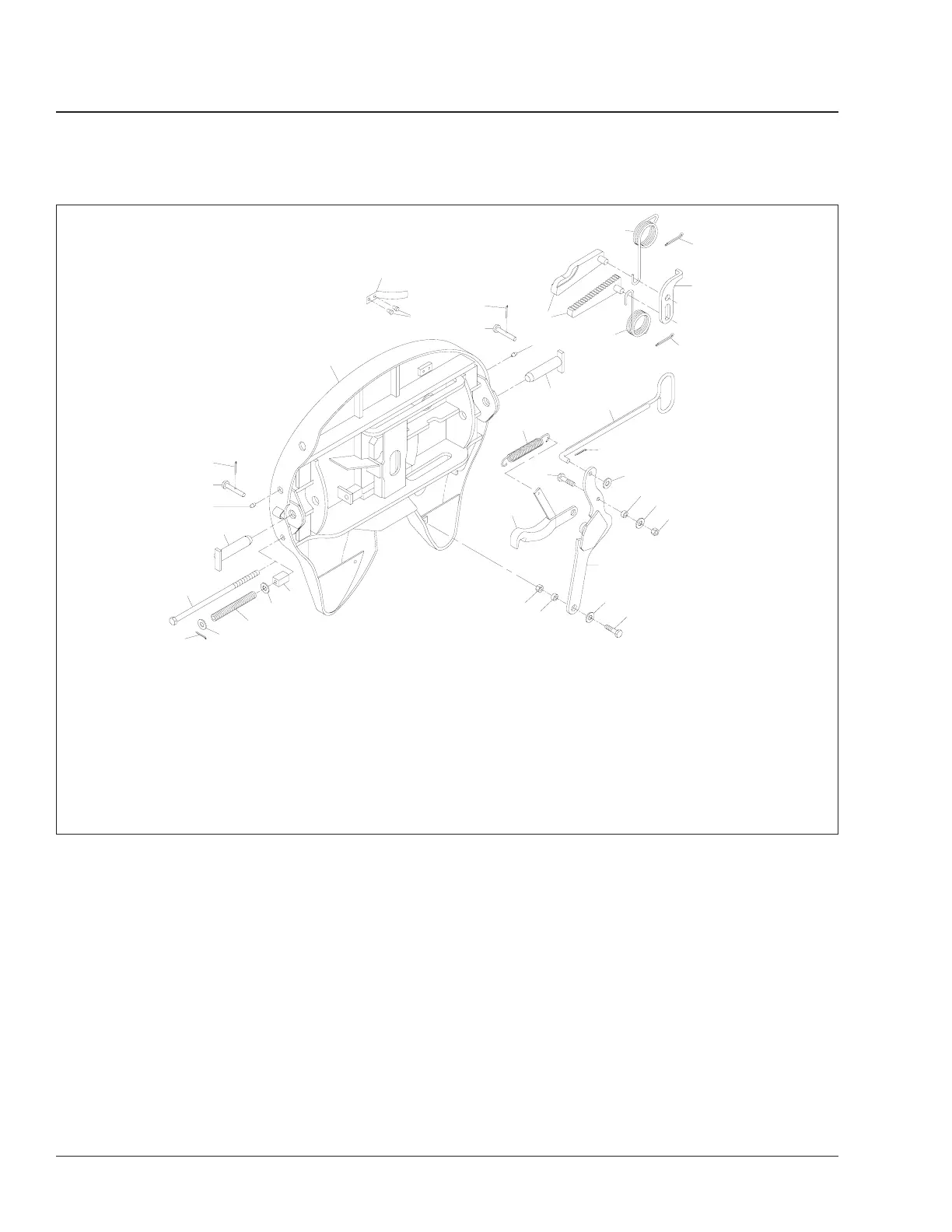

f310476

09/18/95

1

2

3

4

5

6

7

6

8

1

9

10

11

12

3

4

1

2

18

13

14

15

14

16

17

1

21

21

21

22

23

23

24

25

26

20

19

1. 3/16" x 1" Cotter Pin

2. Lower Bracket Retainer Pin

3. Grease Fitting

4. Lower Bracket Pin

5. Wedge Stop Rod

6. Flatwasher

7. Wedge Stop Rod Spring

8. Wedge Stop Rod Nut

9. Side Release Upper Assembly

10. Leaf Spring

11. 1/4–20 x 3/8" Thread-Cutting

Screw

12. Step Jaw and Wedge

13. Jaw Spring

14. 1/4" x 3" Cotter Pin

15. Timer

16. Wedge Spring

17. Pull Handle

18. Bumper Handle Spring

19. 1/2–13 x 2" Bumper Pivot Bolt

20. Bumper

21. Flatwasher

22. 5/16" Bumper Pivot Bushing

23. 1/2–13 Locknut

24. 7/16" Handle Pivot Bushing

25. Operating Handle (side-release

only)

26. 1/2–13 x 2" Handle Pivot Bolt

Fig. 1, Fontaine H5092 Series Fifth Wheel (left-side-release shown)

Frame and Frame Components31

Century Class Trucks Maintenance Manual, January 200731/2

Loading...

Loading...