Try to move the torque rod ends using your

hands only, and check for any free-play. If free-

play is felt, replace the torque rod end bushing.

Do not use a pry bar to check for free-play. Use

of a pry bar may lead to premature bushing re-

placement.

2. Lift the rear of the vehicle and support the frame

on jack stands to unload the suspension compo-

nents. The vehicle is lifted high enough when the

beam ends are off of the saddles. All jack stands

must be of sufficient strength and rigidity to

safely support the vehicle. Do not perform any

work on or around a vehicle that is supported

solely by a lifting device.

Inspect the walking beam for cracks or other

damage. If damage is found, replace the walking

beam.

Keep the vehicle supported by the jack stands

for the next operation.

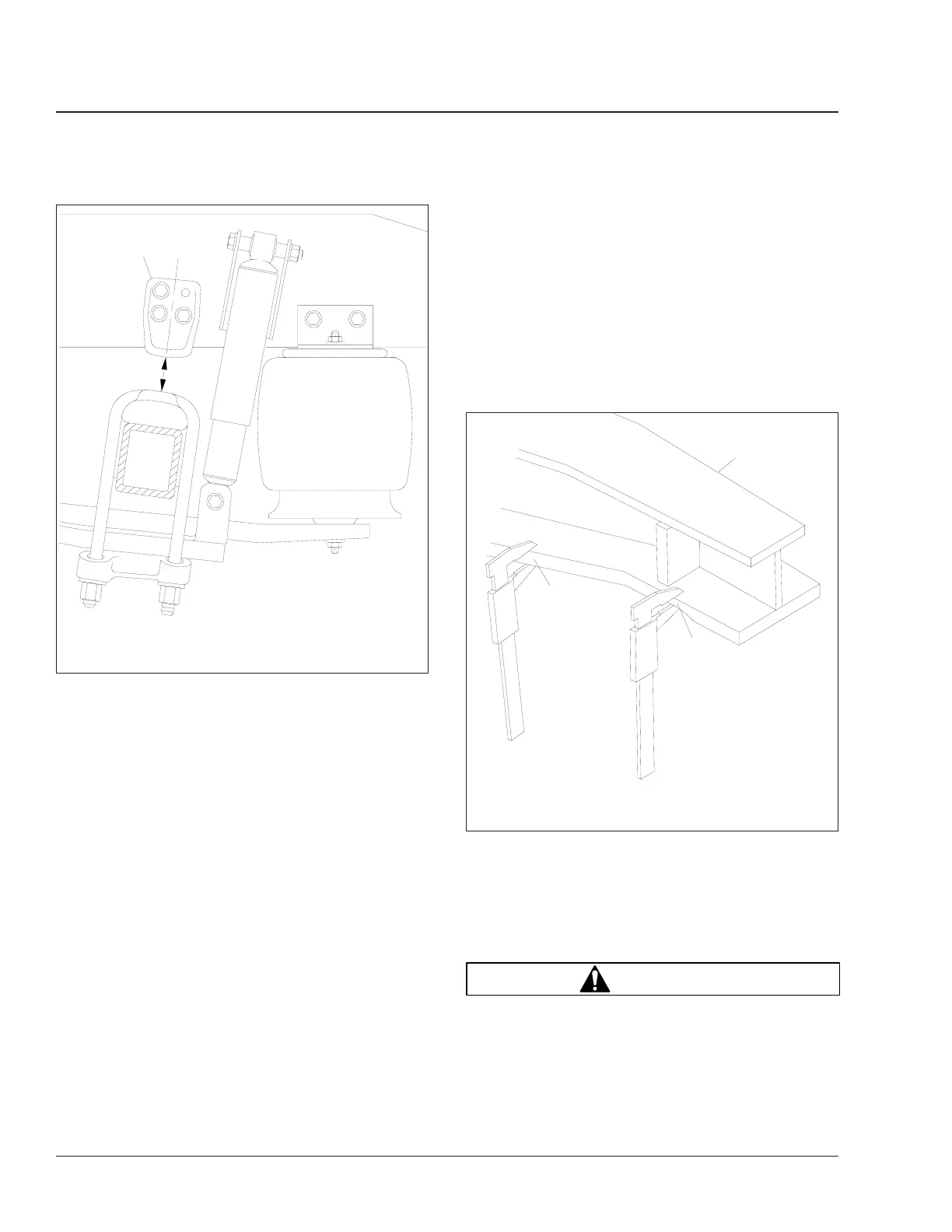

3. Manipulate the walking beam so that a microme-

ter, vernier, or dial caliper may be used to deter-

mine the wear area thickness on the bottom

face. See Fig. 7. Measurements should be taken

a minimum of 1/2 inch from the beam flange

edges to eliminate any edge wear that may have

occurred. Subtract the wear area thickness (see

Fig. 7, Ref. B) from the thickness at the non-

wear area (see Fig. 7, Ref. A) to determine the

amount of wear.

If the beams show any wear greater than 0.062

inch (1.5 mm), a Chalmers wear plate must be

installed, or the walking beam must be replaced.

4. Rotate the restrictor cans 360 degrees and visu-

ally inspect the cans for cracks, severe corro-

sion, and distortion. If any of these conditions are

present, or the restrictor can is missing, replace

the restrictor can.

WARNING

Replace all cracked or missing restrictor cans.

Failure to do so could lead to loss of vehicle con-

trol, which could result in property damage, seri-

ous personal injury or death. Vehicles with

cracked or missing restrictor cans may be driven

08/16/96

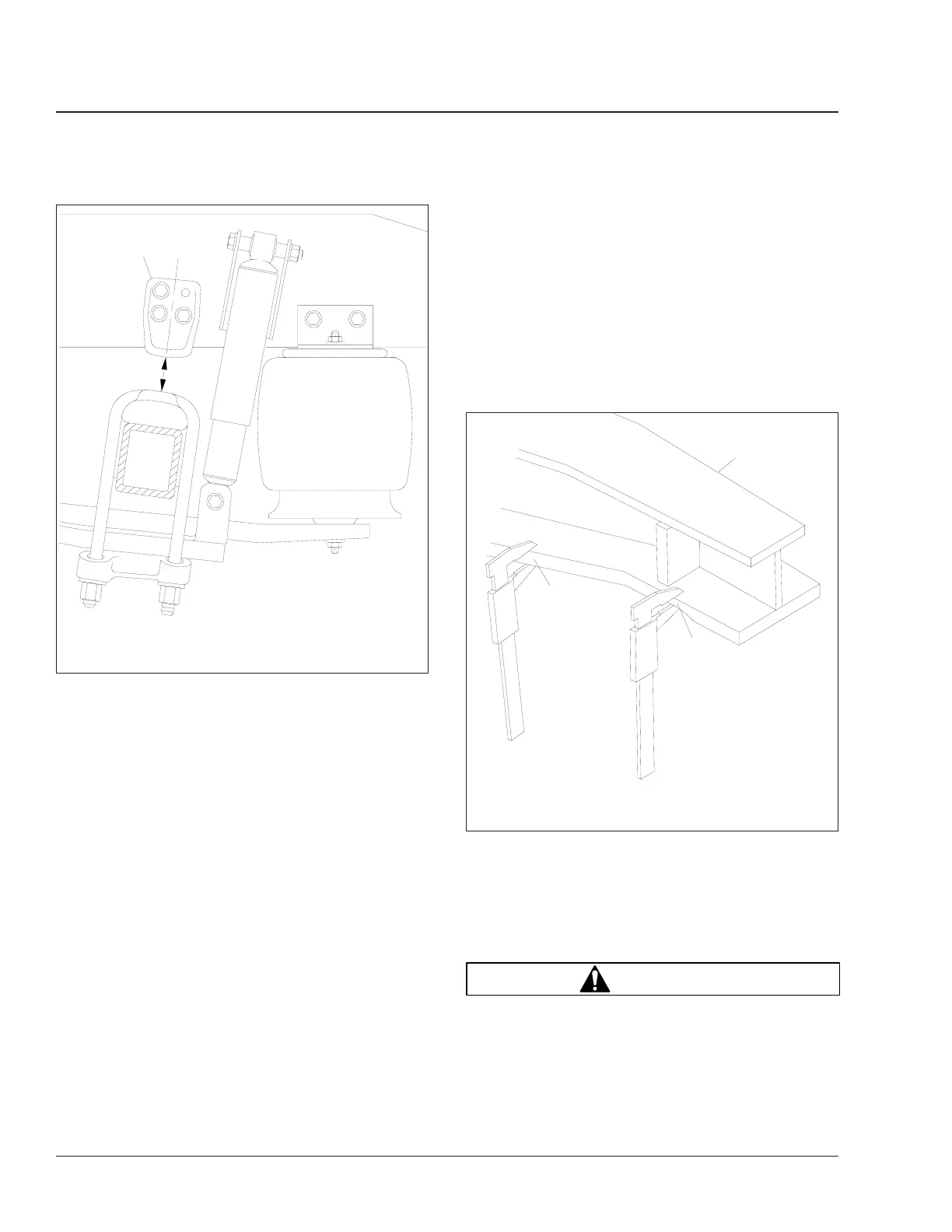

f320453

A

1

A. Measure height here.

1. Left Forwardmost Axle Stop

Fig. 6, AirLiner Axle Stop Measurement

09/27/95

f320432

1

A

B

A. Non-Wear Area B. Wear Area

1. Walking Beam

Fig. 7, Walking Beam End Wear Thickness

Suspension32

Century Class Trucks Maintenance Manual, July 199932/4

Loading...

Loading...