slowly to the nearest workshop for restrictor can

replacement.

Hendrickson RS Series

1. Inspect the frame hangar to frame attaching fas-

teners for the proper torque. See Group 00 of

this manual for torque specifications.

WARNING

Be sure that fasteners are torqued correctly. Fas-

teners that do not provide a tightly clamped joint

between the frame and the hanger can cause pre-

mature fracture of the frame hanger, separation of

components, loss of vehicle control, and possible

personal injury or property damage.

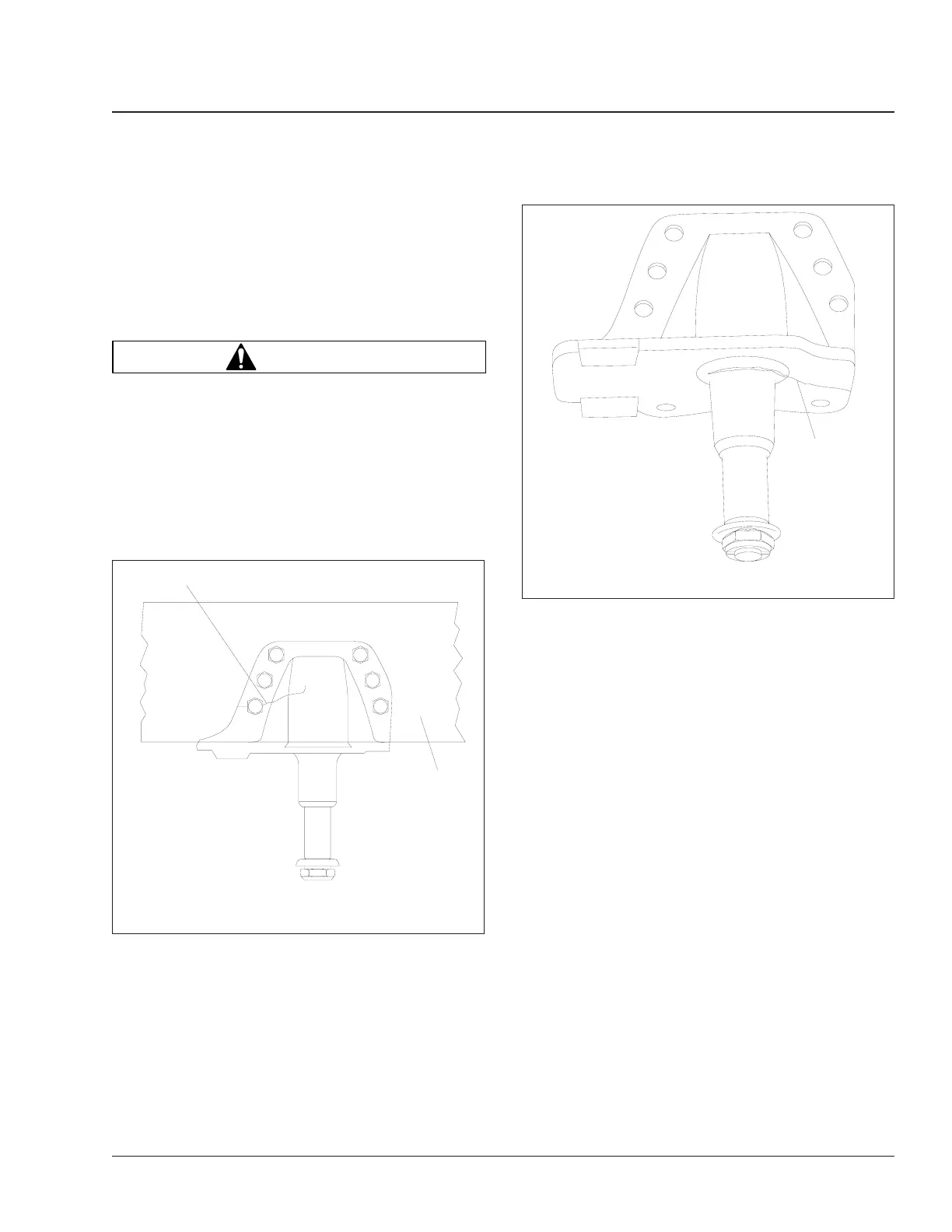

2. Inspect each frame hangar for any evidence of

cracks in the vertical mounting flange. See

Fig. 8.

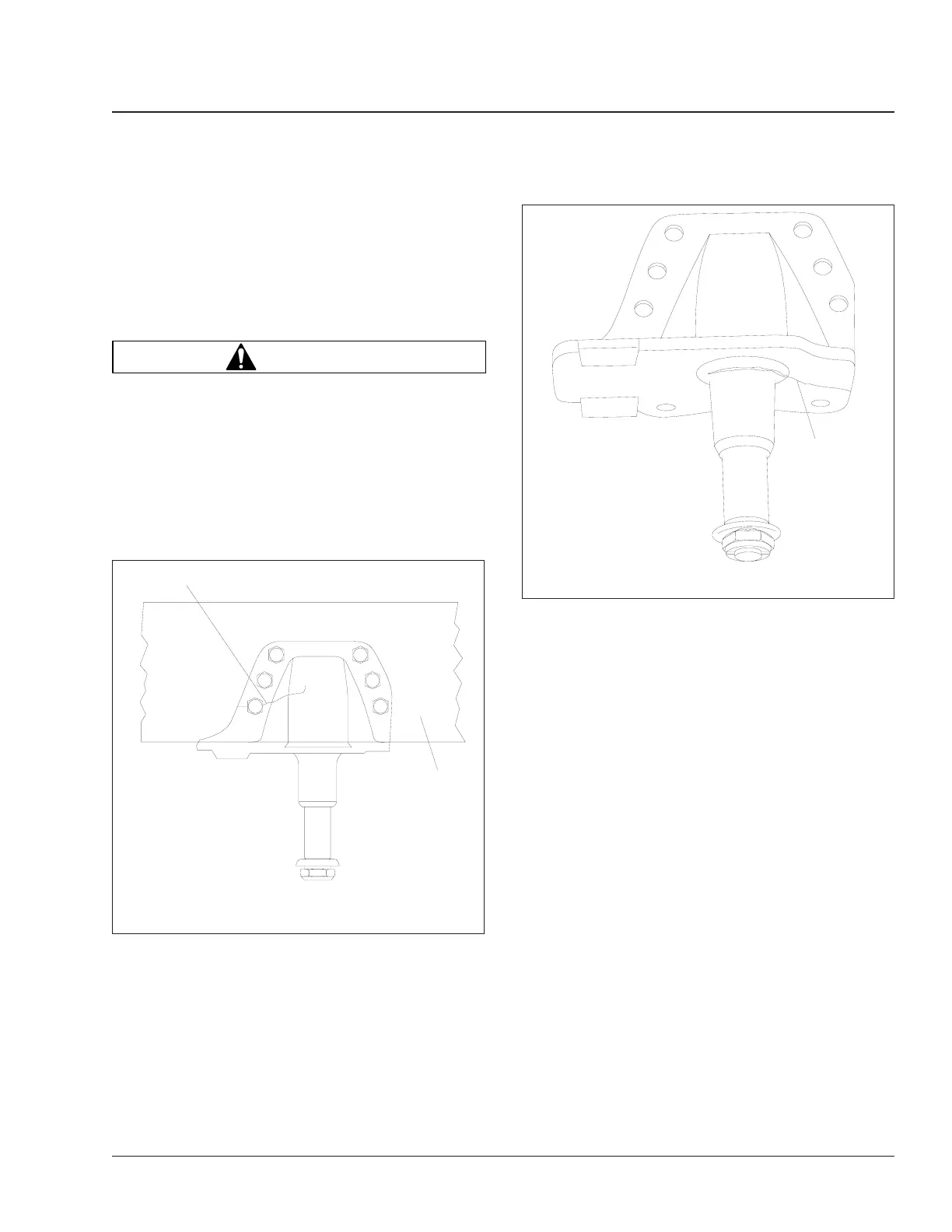

3. Inspect each frame hangar for evidence of

cracks in the horizontal mounting flange adjacent

to the vertical drive pin area. See Fig. 9.

4. Inspect each frame hangar for severe rust on the

horizontal mounting flange adjacent to the verti-

cal drive pin area. See Fig. 10.

5. Inspect the load cushions for cuts and swelling.

Cushions cut by the retaining lips of the saddles

or frame hangars indicate the cushions may not

be the correct hardness or configuration for the

vehicle operation.

6. Inspect the lower side of the vertical drive bush-

ings for evidence of torn or shredded rubber.

Check that the concave washers are installed

with the lips pointing downward.

7. Inspect the saddles and saddle cap fasteners for

wear. The allowable thrust washer wear in alumi-

num saddles is up to 3/16 inch (4.8 mm) into the

saddles as measured at the top of the thrust

washer diameter. Check that the locknuts are

torqued to specification to prevent wear of the

beam center bushings into the legs of the

saddles. See Group 00 of this manual for torque

specifications.

Hendrickson RT2 and RTE2 Series

1. Park the vehicle on a level surface, apply the

parking brakes, and chock the front tires.

09/15/95

f320419

1

2

1. Frame Rail

2. Crack In Inspection Area

Fig. 8, Hendrickson RS Series Vertical Mounting Flange

09/15/95

f320420

1

1. Crack In Inspection Area

Fig. 9, Hendrickson RS Series Horizontal Mounting

Flange

Suspension 32

Century Class Trucks Maintenance Manual, July 1999 32/5

Loading...

Loading...