• 44 lbf·ft (60 N·m) for all ZF Meritor

FreedomLine automated transmissions.

• 35 to 50 lbf·ft (48 to 67 N·m) for all other

Meritor transmissions.

9. Operate the vehicle to check for correct opera-

tion.

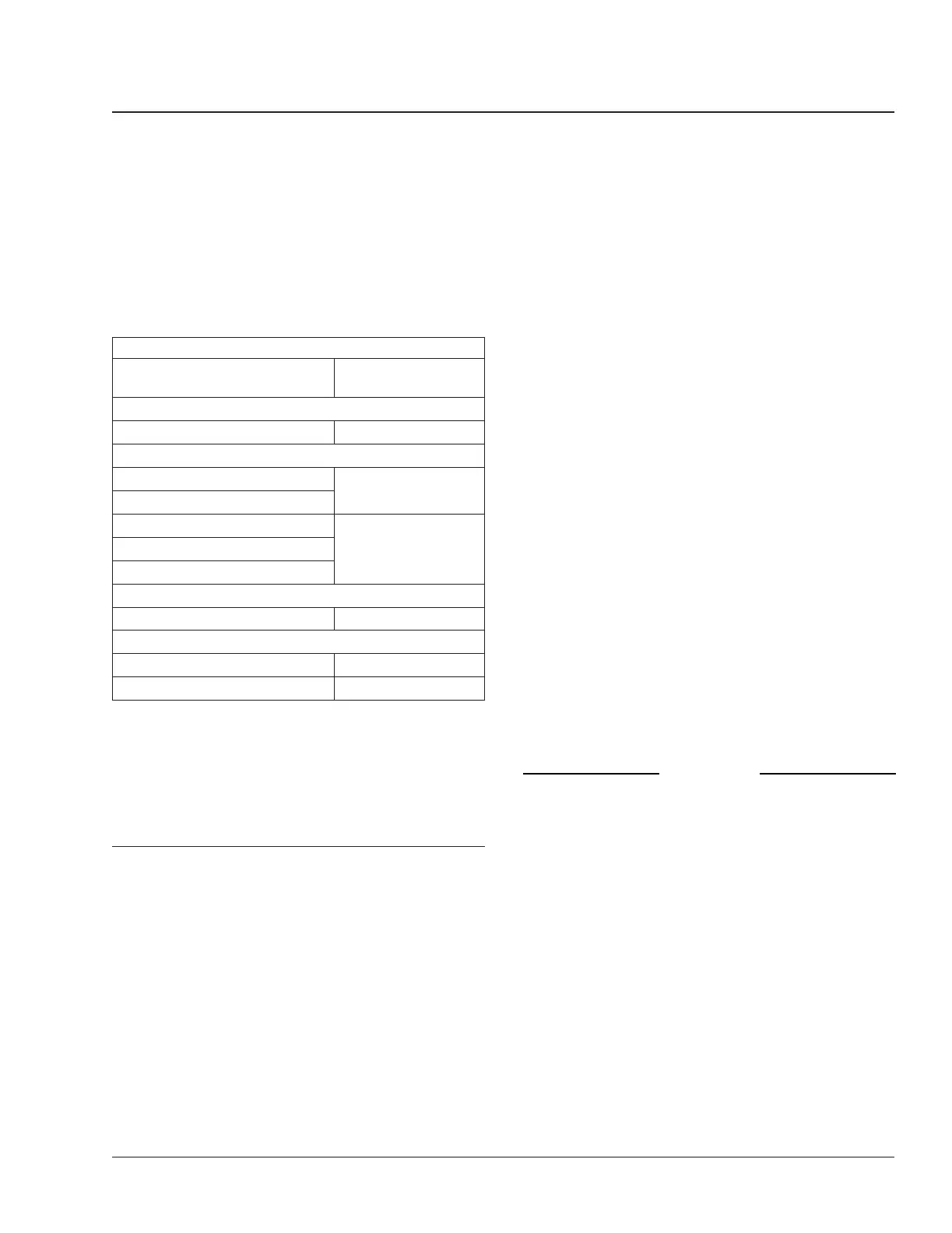

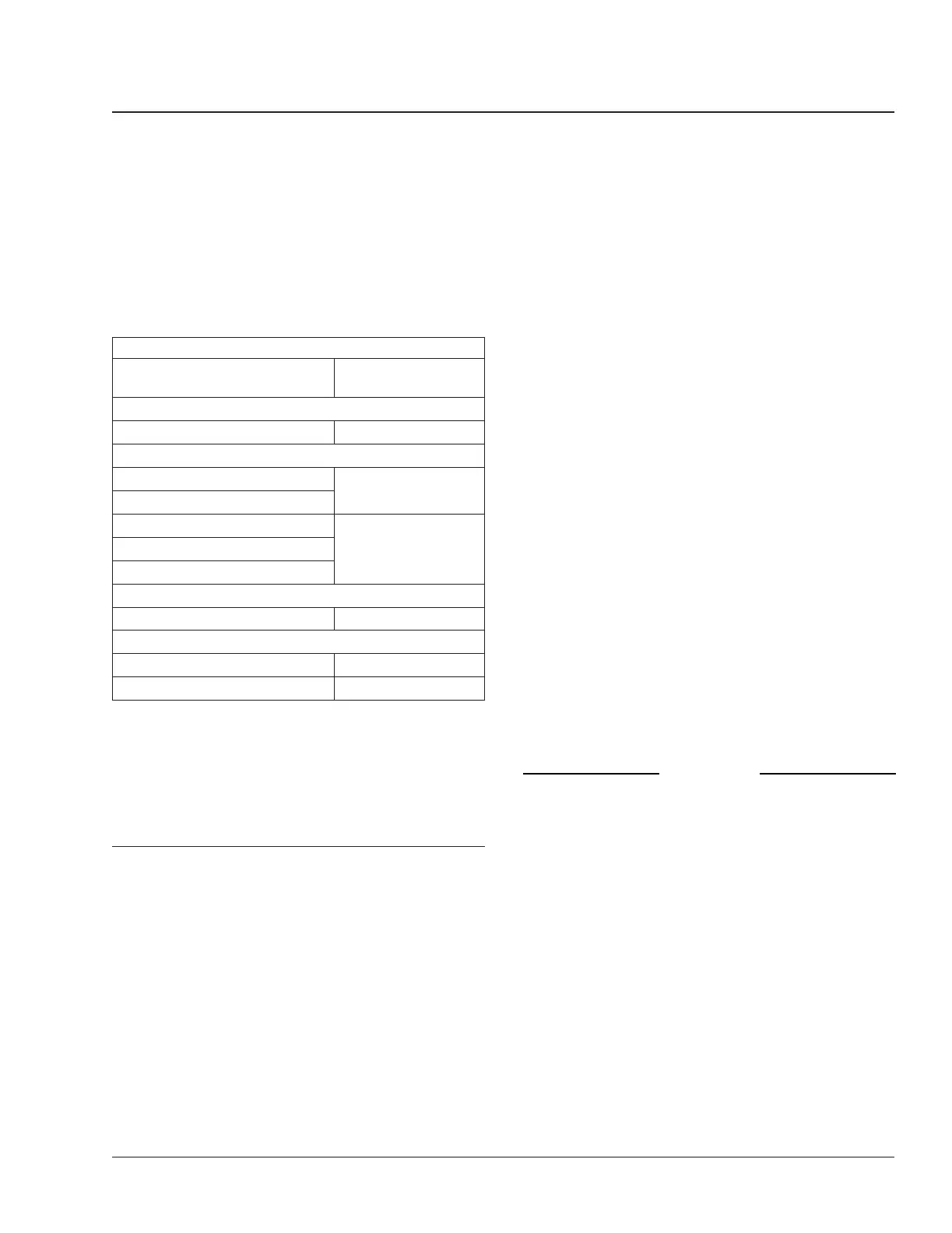

Meritor Transmission Lubricant Capacities

Transmission Model

Refill Capacity

*

:

qt (L)

Meritor M/MO Series

M/MO (all) 10.25 (9.7)

Meritor 9- and 10-Speed

–115A/B/C/R (all)

10.0 (9.5)

–125A/B/C/R (all)

–135A/B/C/R (all)

10.25 (9.7)–145A/B/C/R (all)

–155A/B/C/R (all)

Meritor 13-Speed

RM013–145A 11.0 (10.4)

ZF Meritor FreedomLine

All 12-Speed Models 11.6 (11.0)

All 16-Speed Models 12.5 (11.8)

*

Quantities listed are approximate. Fill the transmission until lubricant is

level with bottom of the fill hole, with the vehicle in normal operating posi-

tion.

Table 3, Meritor Transmission Lubricant Capacities

26–02 Allison Transmission

Fluid and Filter Change

When draining transmission fluid, check for evidence

of dirt or water contamination. A small amount of

condensation will appear in the fluid during operation.

Water contamination is normally characterized as a

milky discoloration of the transmission fluid. Obvious

contamination of the transmission fluid indicates a

leak between the water and fluid areas of the trans-

mission cooler. Inspect and pressure-test the cooler

to confirm the leak; replace leaking transmission

coolers.

1. Drain the transmission when the fluid is warm. If

not already warm, run the engine until the trans-

mission reaches normal operating temperature:

160 to 200°F (71 to 93°C).

2. Park the vehicle on a level surface. Apply the

parking brakes and chock the rear tires.

3. Clean the area around the drain plug and the

transmission fluid pan. Place a drain pan under

the transmission and remove the drain plug. Ex-

amine the fluid as it drains.

4. Remove the 12 mounting bolts (six each) from

the two filter covers.

NOTE: A lot of fluid will drain when the filter

covers are removed.

5. Remove the filter covers, O-rings, and two

square-cut seals from the transmission. See

Fig. 2.

6. Remove the filters from the bottom of the control

module.

7. Lubricate the new O-rings with transmission fluid,

and install them on the cover assemblies.

8. Install a new square-cut seal on each cover as-

sembly, and install the fluid filter elements on the

cover assemblies.

9. Install the filter and cover assemblies into the

filter compartment.

10. Align each cover assembly with the holes in the

channel plate sump, and push the cover assem-

blies in by hand to seat the seals.

NOTICE

Do not use the bolts to draw the filter covers to

the sump. This can damage the covers, seals, or

sump.

11. Install six bolts in each cover, and torque the

bolts 38 to 44 lbf·ft (51 to 61 N·m).

12. Replace the drain plug O-ring, and install the

drain plug. Tighten the drain plug 18 to 24 lbf·ft

(25 to 32 N·m).

13. Refill the transmission with fresh automatic trans-

mission fluid and check the fluid level. See

Table 4 for transmission lubricant capacities, and

Table 5 for approved transmission lubricants.

Transmission 26

Century Class Trucks Maintenance Manual, August 2017 26/3

Loading...

Loading...