components, as this can introduce moisture and

contaminants into the threads of the fittings and

damage the sealants.

Gas detection sensors are located on the cab

overhead console and in the engine compartment

on the frontwall. The sensors are located in high

areas, where rising gas vapors will pass by or

accumulate. Do not use a high-pressure washer,

steam cleaner, or silicone-based chemicals on the

gas detection sensors, as this may permanently

disable the sensors. When cleaning the vehicle,

cover the sensors with a plastic covering. Keep

the sensors covered until the area has been

cleared of any cleaning fumes. Harsh chemicals

and extremely high temperatures may damage the

sensor.

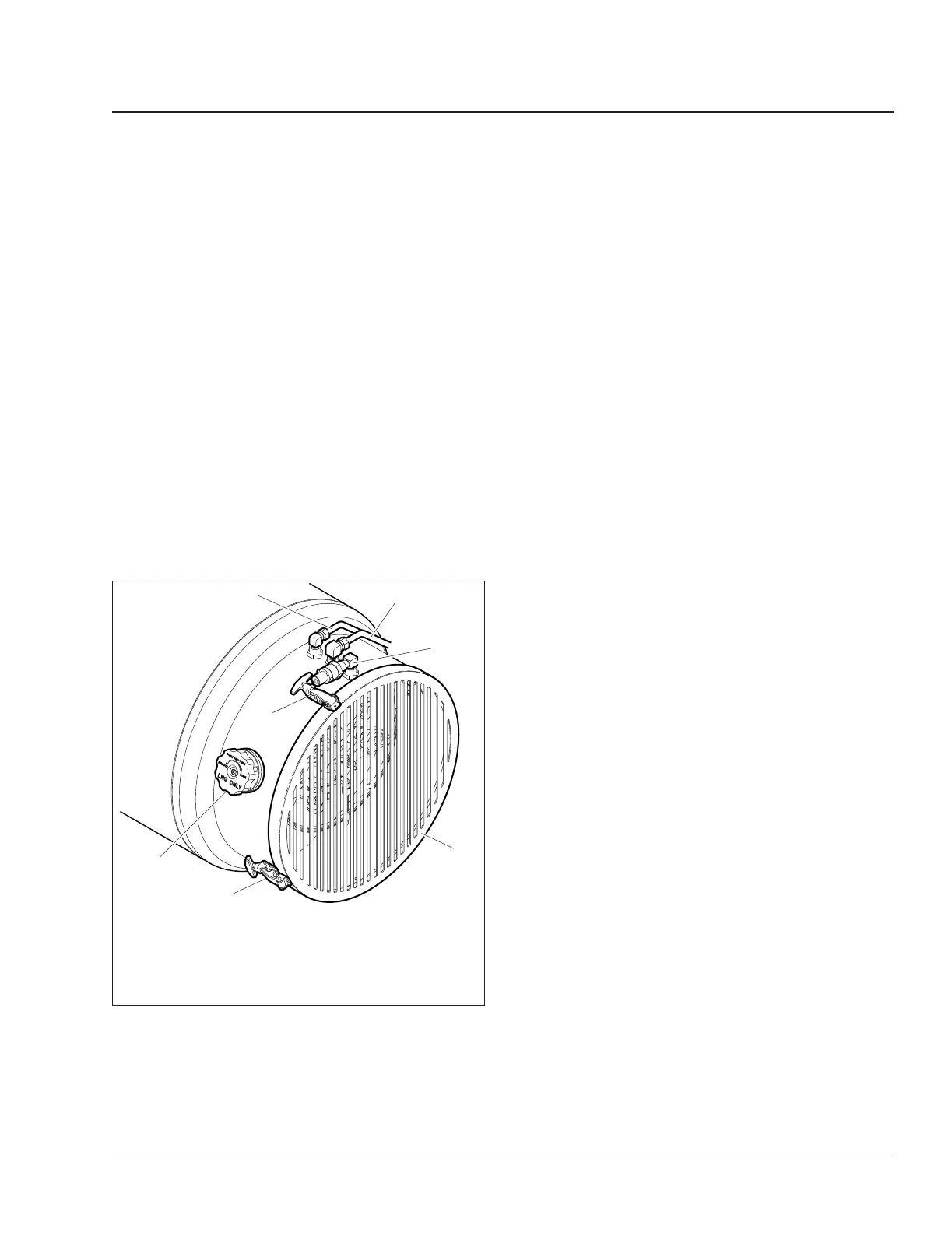

Fuel Tank and Shroud Inspecting

See Fig. 6 for fuel tank and shroud component

locations.

1. Inspect the fuel tank outer shell for dents or

other signs of damage. Inspect the bottom of the

tank for deep scratches, flat spots, or gouges.

Replace a leaking fuel tank.

2. Ensure that the fuel tank is secured to its

mounting brackets and that the mounting

brackets are secured to the frame. Inspect for

any signs of looseness.

3. Ensure that all rubber isolator straps are present

and secure.

4. Look for signs of abrasion between the fuel tank

and mounting brackets.

5. Inspect the fuel fill fitting for signs of damage or

leaks. Ensure the fuel fill cap is present and in

good condition, and the fitting is mounted

securely on the tank.

6. Inspect the fuel outlet line and fitting for signs of

leaks or damage.

7. Inspect the primary relief vent and pipe-away line

for damage, kinks, chafing, or loose connections.

8. Inspect the fill vent fitting for signs of damage.

9. Inspect the shroud cover for dents or other signs

of damage. Ensure that the shroud cover latches

are in working condition and fasten the shroud

cover securely to the tank.

10. Replace leaking or damaged fuel lines. Repair or

replace leaking or damaged fittings.

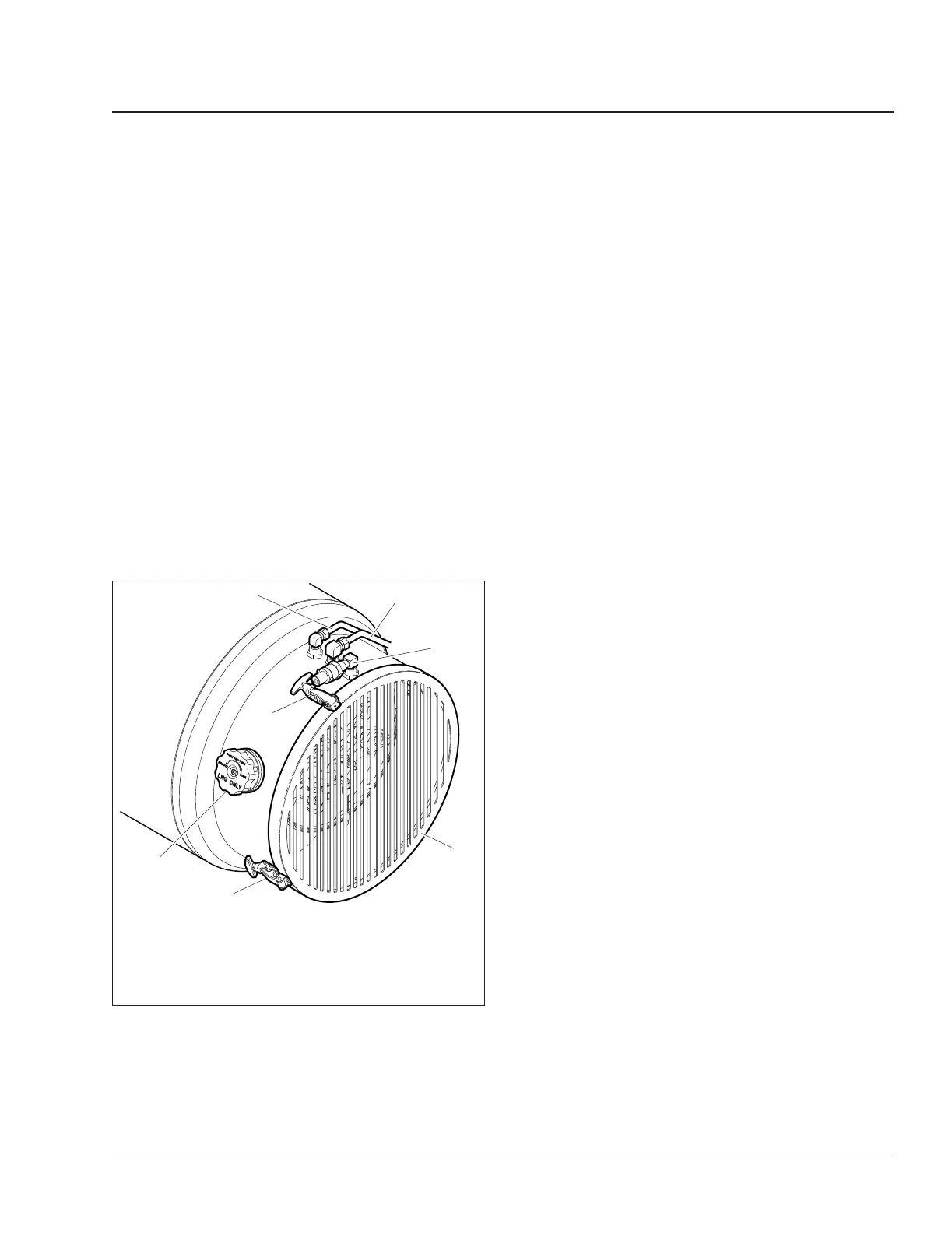

Plumbing Components

Inspecting

See Fig. 7 for plumbing component locations.

Use a bubble solution to check for leaks while

performing the following visual inspection.

1. Check the following components for signs of

damage or leaks.

• Pressure control regulator

• Vapor shutoff valve

• Secondary relief valve

• Primary relief valve and threaded

connections

• Excess flow valve

• Fuel shutoff valve

• Fill check valve

2. Inspect the fuel fill line for signs of damage,

kinked or crushed piping, or chafing.

05/29/2009 f470534

1

2

3

4

6

5

6

1. Fuel Fill Fitting

2. Fuel Outlet Line

(liquid)

3. Primary Relief Vent

Line (relief valve)

4. Fill Vent Fitting (vent)

5. Shroud Cover

6. Shroud Cover Latches

Fig. 6, Fuel Tank Outer Shell

Fuel 47

Business Class M2 Plus Maintenance Manual, 02/10/2023 47/5

Loading...

Loading...