2.2 Clean the area around the fill plug or the

dipstick tube. Remove the fill plug from

the gear case, if applicable.

3. Clean the magnetic plug(s) before installing it.

Use a piece of key stock, or any other

convenient steel slug, to short the two magnetic

poles and divert the magnetic field.

4. Install and tighten the drain plug(s) 50 lbf·ft (68

N·m).

Filling

NOTICE

Operating a transmission with the fluid level

higher or lower than recommended can result in

transmission damage. Do not overfill the

transmission; overfilling will force fluid out of the

case through the main shaft openings. Fluid

overflow may also drain onto the clutch or clutch

brake, causing additional problems.

IMPORTANT: Do not mix types of fluid, because

of possible incompatibility. Do not use multi-

viscosity fluids or EP (Extreme Pressure) gear

fluids. Do not use fluid additives or friction

modifiers. If switching from a petroleum-based

lubricant to a synthetic lubricant, all areas of

each affected component must be thoroughly

drained. Switching to a synthetic lubricant, when

a petroleum-based lubricant has been used for

50,000 miles (80 000 km) or longer may affect

transmission performance. Monitor all seal

areas for the first 10,000 miles (16 000 km)

after changing to a synthetic lubricant from a

petroleum-based lubricant.

NOTE: The correct fluid level is established by

checking at the fill plug opening (manual and

automated).

1. On manual and automated transmssions, add

fluid until it is level with the lower edge of the fill

opening. If the transmission has two fill openings,

add fluid to the level of both fill openings. See

Table 1 for approved transmission lubricants.

See

Table 4 for lubricant capacities.

2. Check and adjust the fluid level using the

applicable Eaton Transmission fluid level

checking procedure in

Group 26.

3. Clean the fill plug (if applicable), then install it in

the transmission. Tighten the plug as follows:

• 25 to 35 lbf·ft (34 to 48 N·m) for Eaton

Fuller transmissions with 3/4-inch pipe

threads.

• 60 to 75 lbf·ft (81 to 102 N·m) for Eaton

Fuller transmissions with 1-1/4-inch pipe

threads.

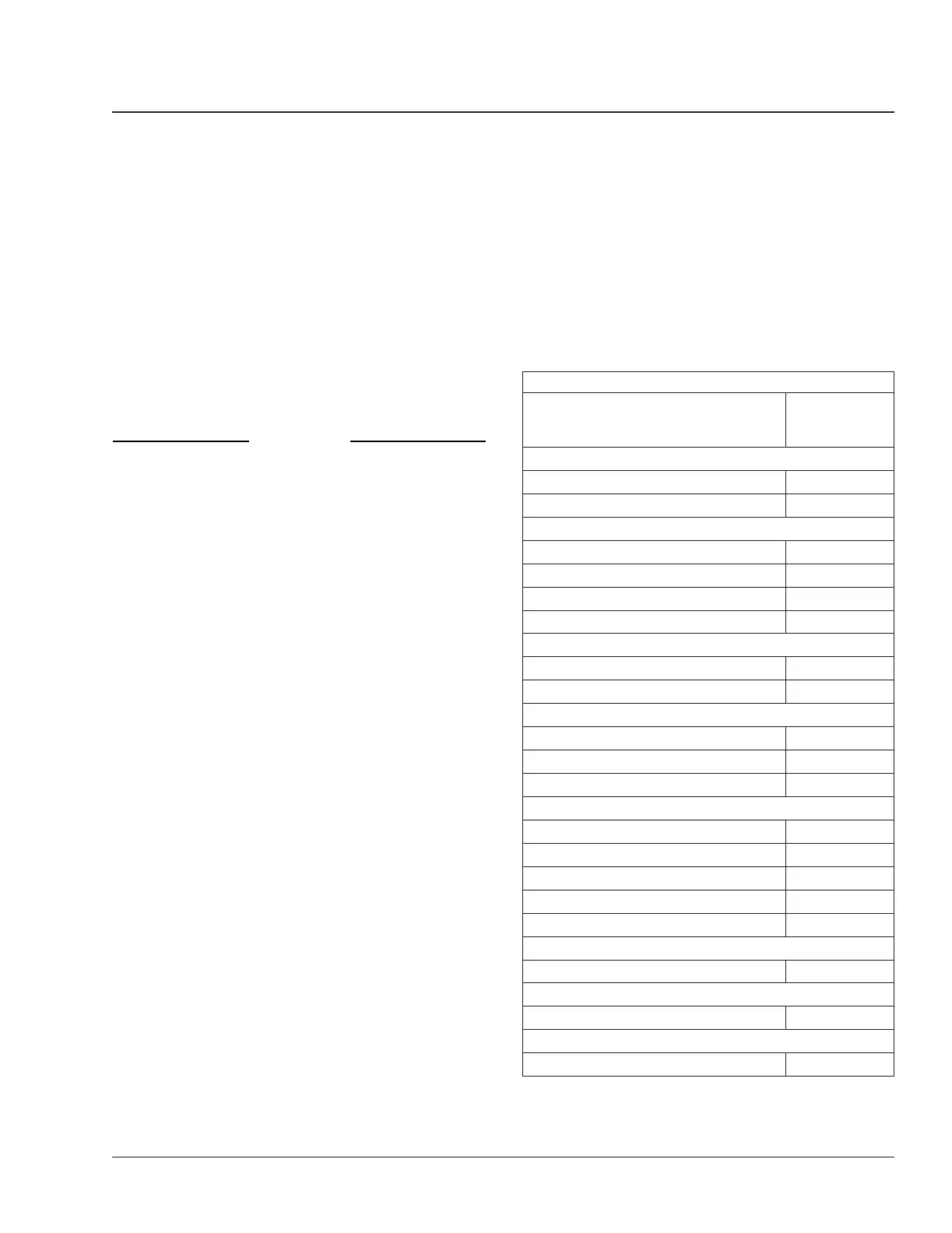

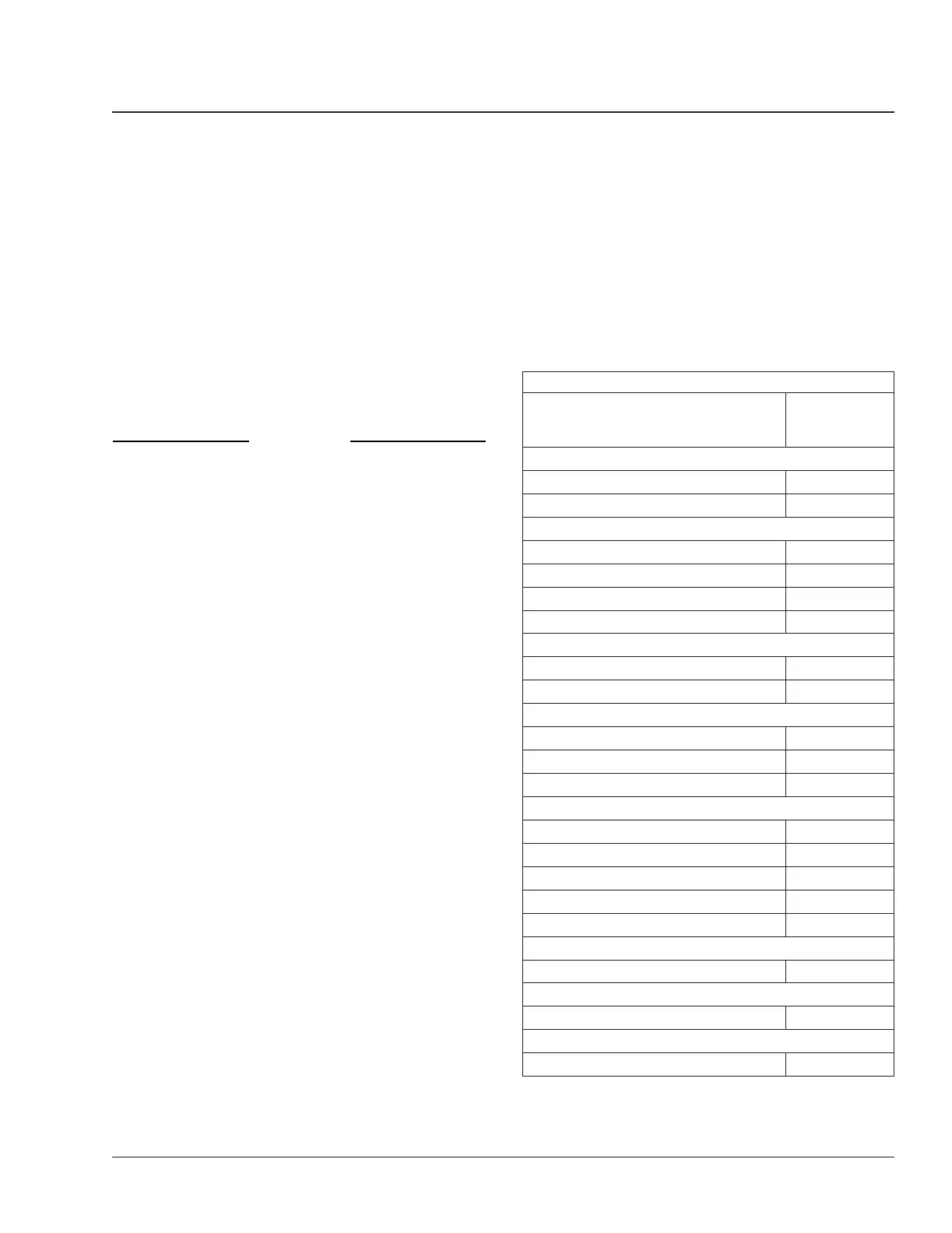

Eaton Fuller Transmission Lubricant Capacities

*

Transmission Model

†

Lubricant

Capacity:

qt (L)

5-Speed

FS–4205A/B, FS–5205A/B 6.25 (5.9)

FS–6305A/B 9.75 (9.2)

6-Speed

FS–5406A 9.75 (9.2)

FS–6406A, FSO–6406A 9.75 (9.2)

FO–6406A, FO-8406 10.5 (10.0)

FSO–8406A 9.75 (9.2)

7-Speed

T–14607A/B 18 (17.5)

TX–14607B 18 (17.5)

9-Speed

RT–6609A 6 (5.7)

RT–8709B 13.0 (12.3)

RT–8608L 13.5 (12.7)

10-Speed

FR–9210B 11.75 (11)

FRO–14210C, FRO–15210C 11.75 (11)

RT–8908LL 14 (13.2)

RTO–10910B AS2 13 (12.3)

RTO–11908LL 14 (13.2)

11-Speed

RTO–11909ALL 14 (13.2)

13-Speed

RTLO–14913A 14 (13.2)

18-Speed

RTLO–14918B 14 (13.2)

Transmission 26

Business Class M2 Plus Maintenance Manual, 02/10/2023 26/5

Loading...

Loading...