If the equalizer beam ends appear lower, use a jack

to raise each beam end, then check for movement of

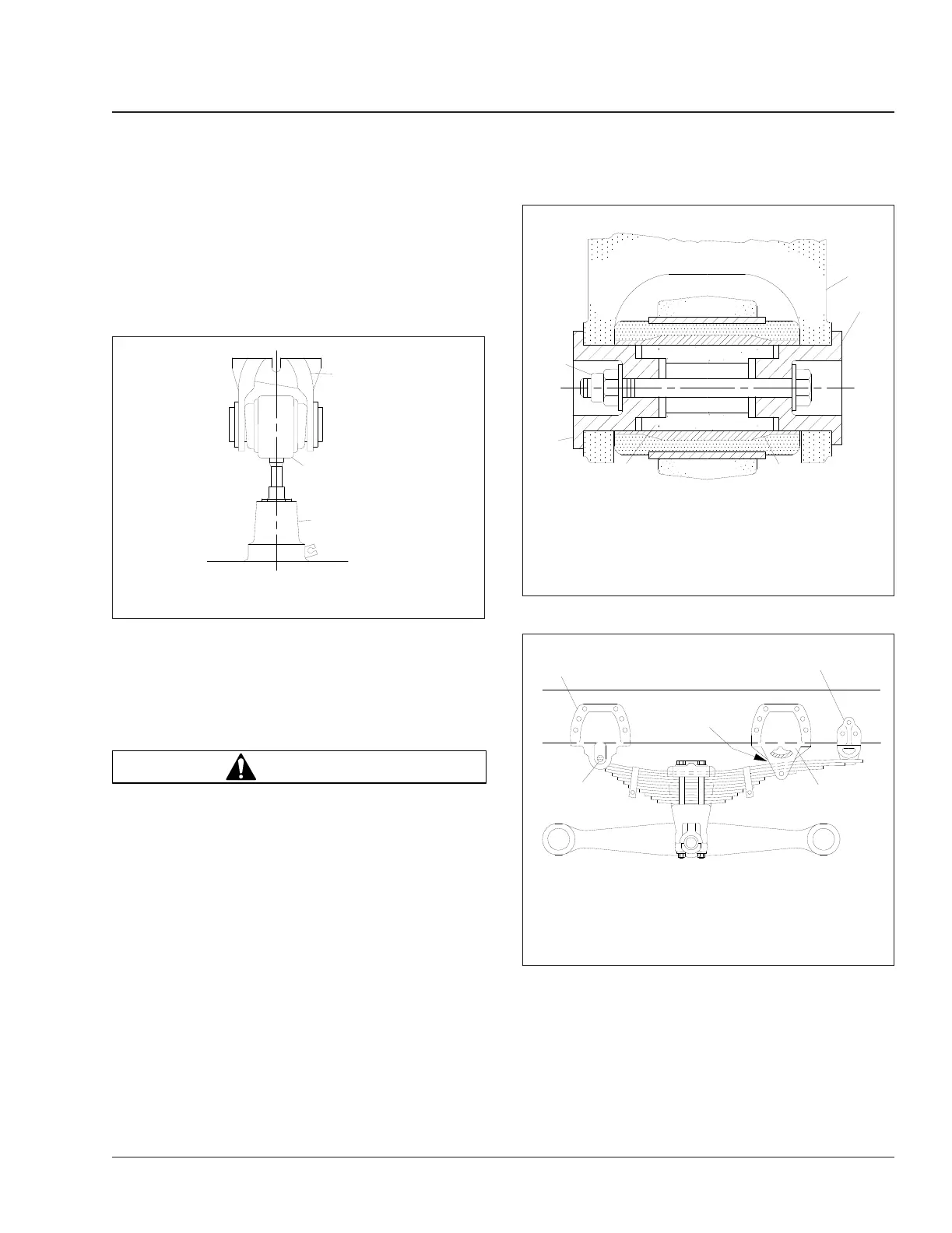

the inner metal of the rubber end bushing. See Fig.

4

. Movement cannot be corrected by tightening the

fastener, because parts could be damaged. If there is

movement, replace the rubber end bushings and all

connecting parts.

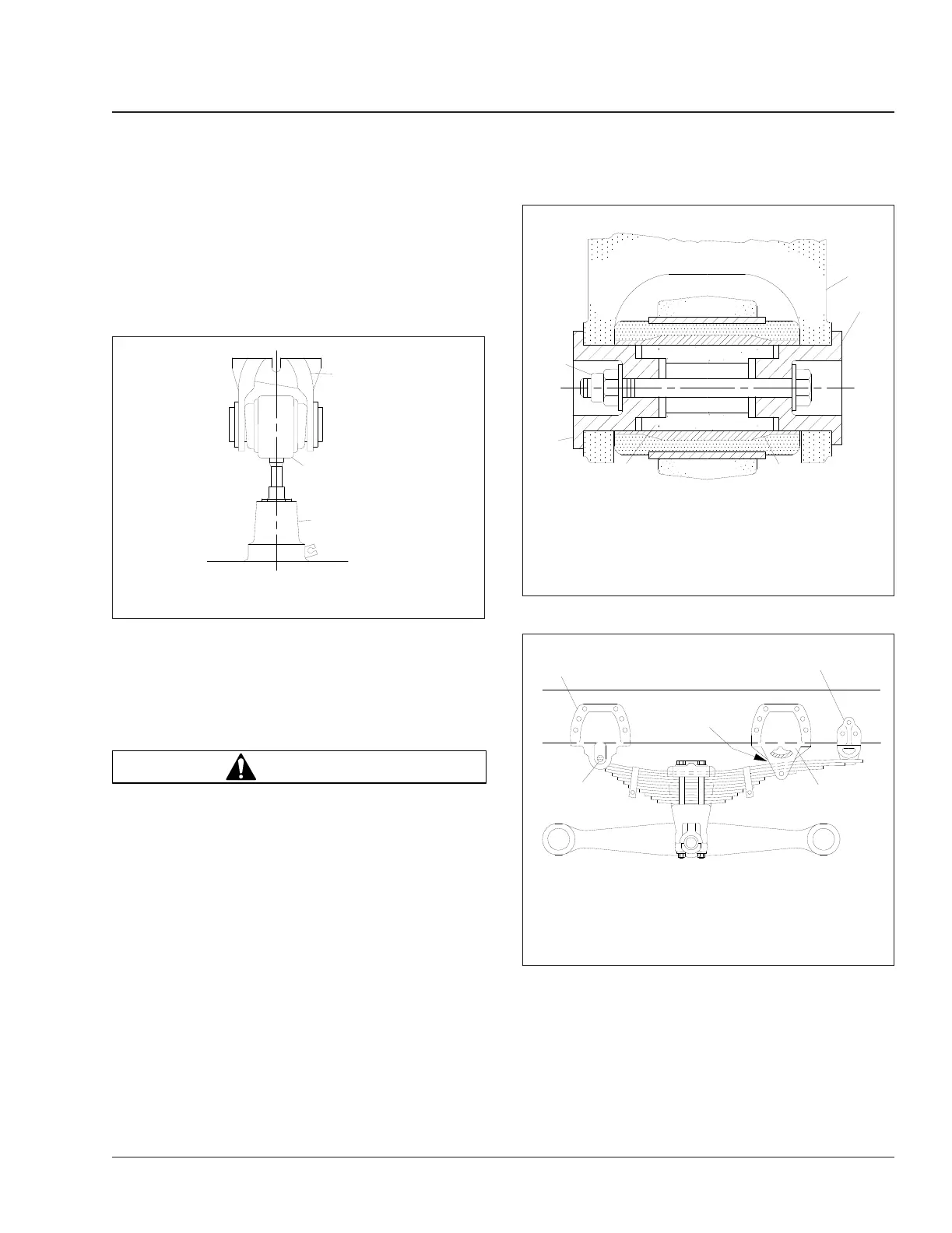

After repairs to the suspension, check the fastener

torque after the vehicle has been in service for 2500

miles (4000 km). Tighten the adapter-type beam end

connection nut 210 to 240 lbf·ft (285 to 325 N·m).

See

Fig. 5. Do not overtighten.

WARNING

Insufficient beam end fastener torque could cause

the beam to separate from the axle. This will

cause loss of vehicle control resulting in property

damage, serious personal injury or death.

Hendrickson Leaf Spring

Assembly Inspection

1. Inspect the spring hangers for wear of the spring

pin holes, cams, and the spring hanger legs. See

Fig. 6.

2. If equipped with the RTE series, the gap

between the rear (no. 2) spring hanger and the

top spring leaf should measure at least 3/8 inch

(9.5 mm) in an unloaded condition.

If the measurement is less than 3/8 inch (9.5

mm), install new rear (no. 3) extension hangers.

Lubricate the bolt threads with SAE 20 oil.

Tighten the 1/2–13 locknuts with hardened

washers 85 lbf·ft (115 N·m).

f320039a

05/27/93

1

2

3

1. Beam Hanger

2. Equalizer Beam

3. Jack

Fig. 4, Raising the Beam End

f320110a

05/27/93

1

2

2

3

4

5

NOTE: Do not use the three-piece adapter without the

intermediate tube.

1. Nut

2. Adapter

3. Intermediate Tube

4. Inner Metal of Beam

End Bushing

5. Beam Hanger

Fig. 5, Three-Piece Adapter-Type Beam End Connection

f320112a

05/27/93

1

2

3

4

A

A. Minimum gap of 3/8 inch (9.5 mm).

1. Forward (no. 1) Spring Hanger

2. Spring Eye Pin

3. Rear (no. 2) Spring Hanger

4. Rear (no. 3) Extension

Fig. 6, Unloaded RTE Spring Suspension

Suspension 32

Business Class M2 Plus Maintenance Manual, 02/10/2023 32/5

Loading...

Loading...