1. Park the vehicle on a level surface, shut down

the engine and set the parking brake. Chock the

tires.

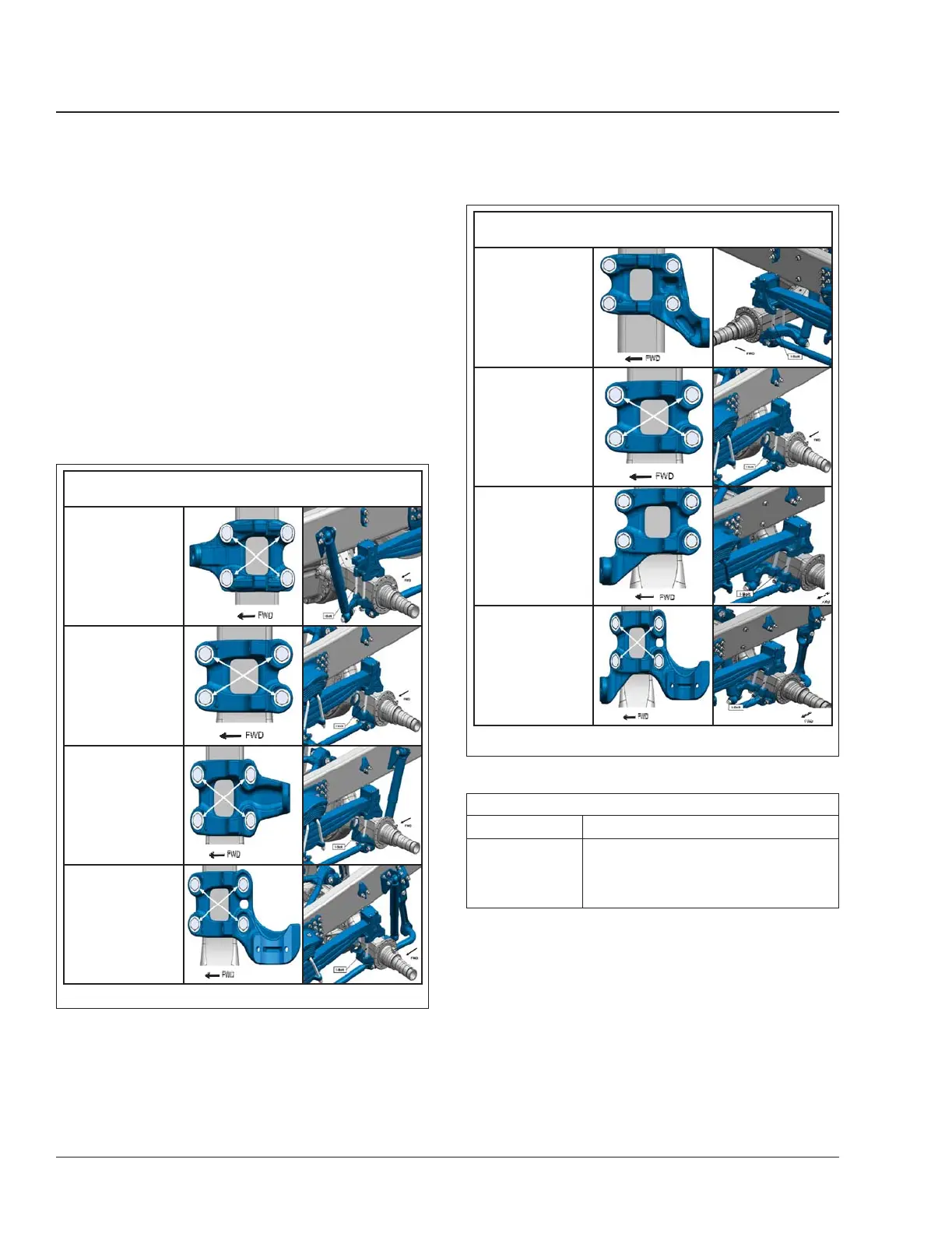

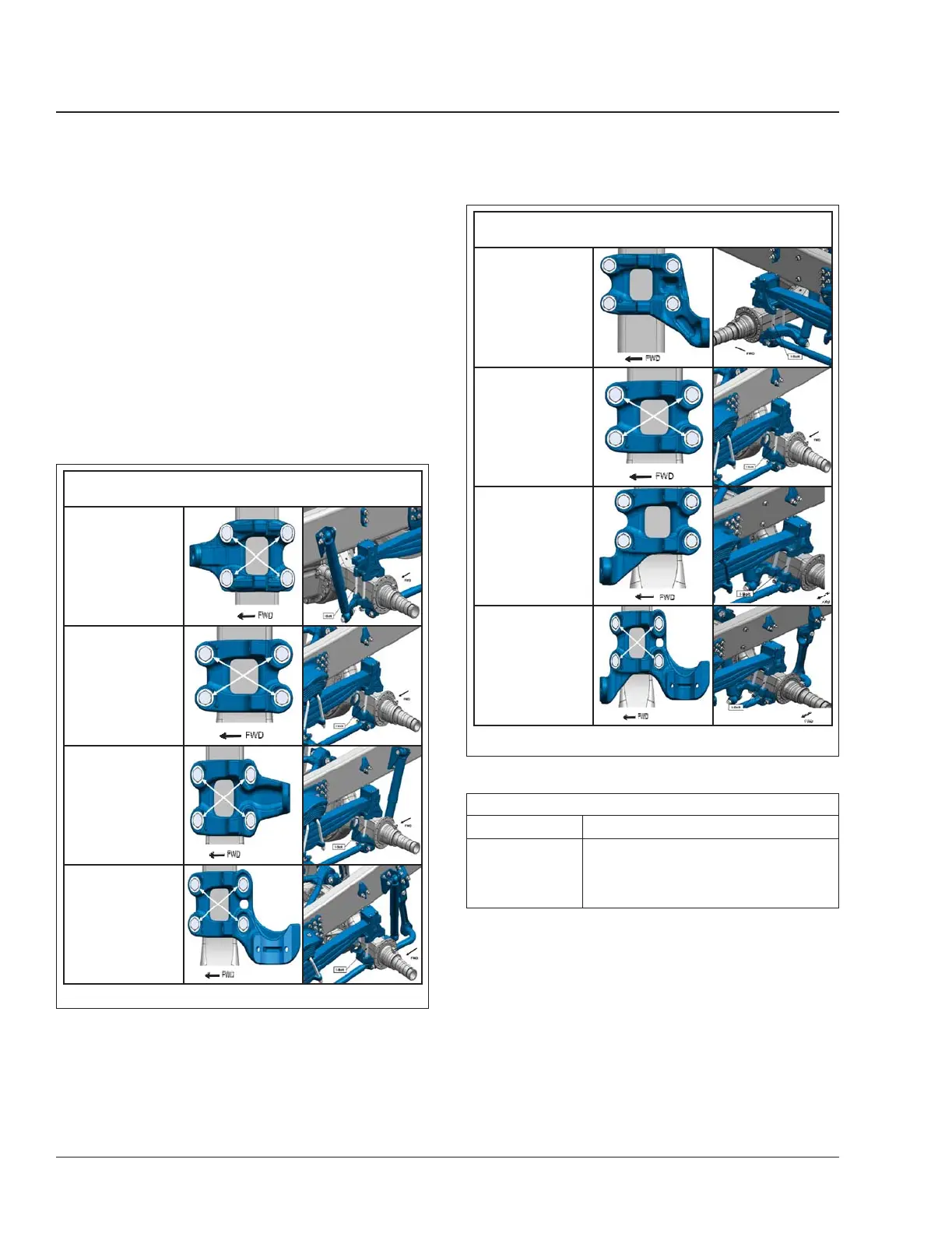

2. Check the I-bolt torque. See

Table 2 for I-bolt

torque specifications. Tighten in a diagonal pat-

tern as shown in

Fig. 9 and Fig. 10. Set a click-

type torque wrench to the mid-point value for the

fastener being checked. Turn the wrench in a

clockwise motion (looking up) until the torque

wrench clicks, then release pressure on the

torque wrench, and turn the torque wrench again

until it clicks. If the bolt turns on the second

application, the bolt is stretching and must be

replaced.

Axle Clamp I-Bolt Torque Values

*

Size Torque: lbf·ft (N·m)

M18–1.5

Stage 1: Hand-tighten

Stage 2: 60 (81)

Stage 3: 150 (203)

Stage 4: 212 to 260 (287 to 352)

*

Tighten in a diagonal pattern as shown in Fig. 9.

Table 2, Axle Clamp I-Bolt Torque Values

f32129502/24/2022

Drum Brakes-Torque Pattern Looking Up

FWD Axle

Rear Axle

No Shock

Rear Axle

with Shock

Rear Axle

with Shock

and Stabilizer

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Fig. 9, Drum Brakes Torque Pattern (looking up)

f32129602/24/2022

Disc Brakes-Torque Pattern Looking Up

FWD Axle

Rear Axle

No Shock

Rear Axle

with Shock

Rear Axle

with Shock

and Stabilizer

1

2 3

4

1

2

3

4

1

2

3

4

1

2

3

4

Fig. 10, Disc Brakes Torque Pattern (looking up)

Suspension32

Business Class M2 Plus Maintenance Manual, 02/10/202332/8

Loading...

Loading...