RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM

Page 50

Adjustable Safety Setpoints

High Discharge Pressure Stop Load _____ Force Unload ____ Alarm ______ Delay _____ Shutdown ____ Delay ____

High Discharge Temp. Stop Load _____ Force Unload ____ Alarm ______ Delay _____ Shutdown ____ Delay ____

Motor Amps ____ Volts _____ Service Factor _______ Horsepower _______ CT Factor ______ Recycle Delay ______

Low Motor Amps Shutdown _____ Delay ______ Force Unload Inhibit Delay ______

High Motor Amps Stop Load _____ Force Unload ____ Alarm ______ Delay _____ Shutdown ____ Delay ____

High Oil Temperature Alarm_______ Delay______ Shutdown______ Delay ______

Low Oil Temperature Alarm_______ Delay______ Shutdown______ Delay ______ High Level Shutdown Delay ____

Low Separator Oil Temp. Alarm_______ Delay______ Shutdown______ Delay ______

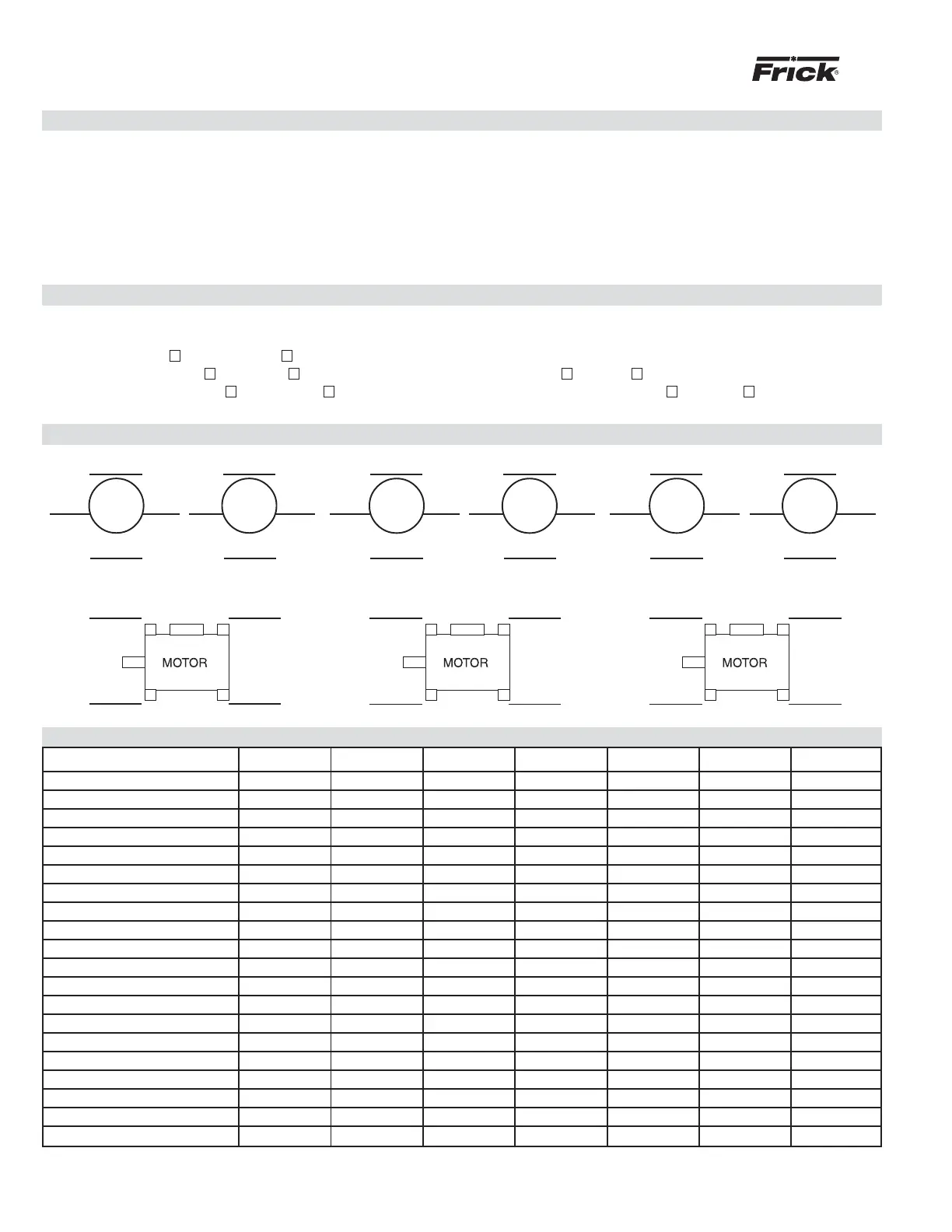

Drive Train Alignment

Ambient Temperature at Time of Alignment _______ Oil Separator Temperature at Time of Alignment ________

Motor Coupling Type __________ Size ___________ Distance Between Coupling Hub Faces _________

Soft Foot Check

OK as Found Shimming Required Amount of Shims used to Correct _________

Indicator Readings in in./1000 mm Indicator Clamped to Motor Compressor

Indicator Readings Facing

Compressor Motor Magnetic Center Checked Marked N/A

Compressor Coupling Hub Runout __________ Motor Coupling Hub Runout____________

Initial Cold Alignment Initial Hot Alignment Final Hot Alignment

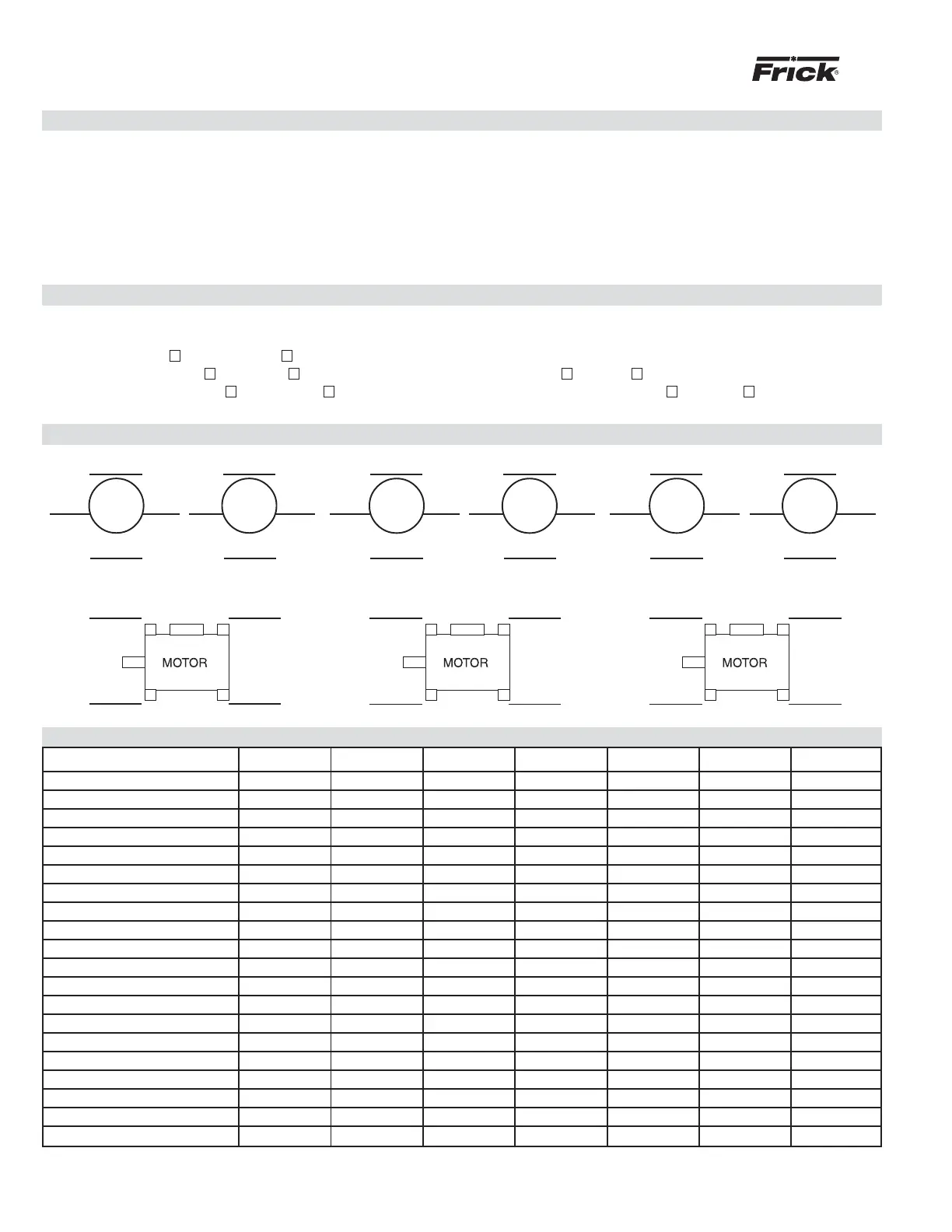

Operating Log Sheet

Date

Time

Hour Meter Reading

Equip. Room Temp.

Suction Pressure

Suction Temperature

Suction Superheat

Discharge Pressure

Discharge Temperature

Corresponding Temperature

Oil Pressure

Oil Temperature

Oil Filter Pressure Drop

Separator Temperature

Slide Valve Position

Volume Ratio (VI)

Motor Amps / FLA %

Capacity Control Setpoint

Oil Level

Oil Added

Seal Leakage (Drops/Min.)

Face Rim

Thickness of Shims Added

Face Rim

Thickness of Shims Added

Face Rim

Thickness of Shims Added

Loading...

Loading...