Boiler maintenance

Inspection and cleaning

Fröling Heizkessel- und Behälterbau Ges.m.b.H

Industriestraße 12 A-4710 Grieskirchen Page 27

Tel +43 (0) 7248 606-0 Fax +43 (0) 7248 606-600 info@froeling.com www.froeling.com B 067 03 11_en

4

4.2 Inspection and cleaning

Regular cleaning of the boiler extends its life and is a basic

requirement for smooth running based on output. So clean the

boiler regularly!

Recommended: When cleaning, use an ash vacuum.

4.2.1 Inspection

Checking the thermal discharge safety device

Check the seal of the discharge valve at regular intervals

The discharge pipe must not drip

Exception: boiler temperature > 95 °C

If water is dripping from the discharge pipe:

Clean the discharge safety device or have the installer replace it if

necessary

Check safety valve

Check the safety valve as per the manufacturer’s instructions.

See the operating instructions of the safety valve

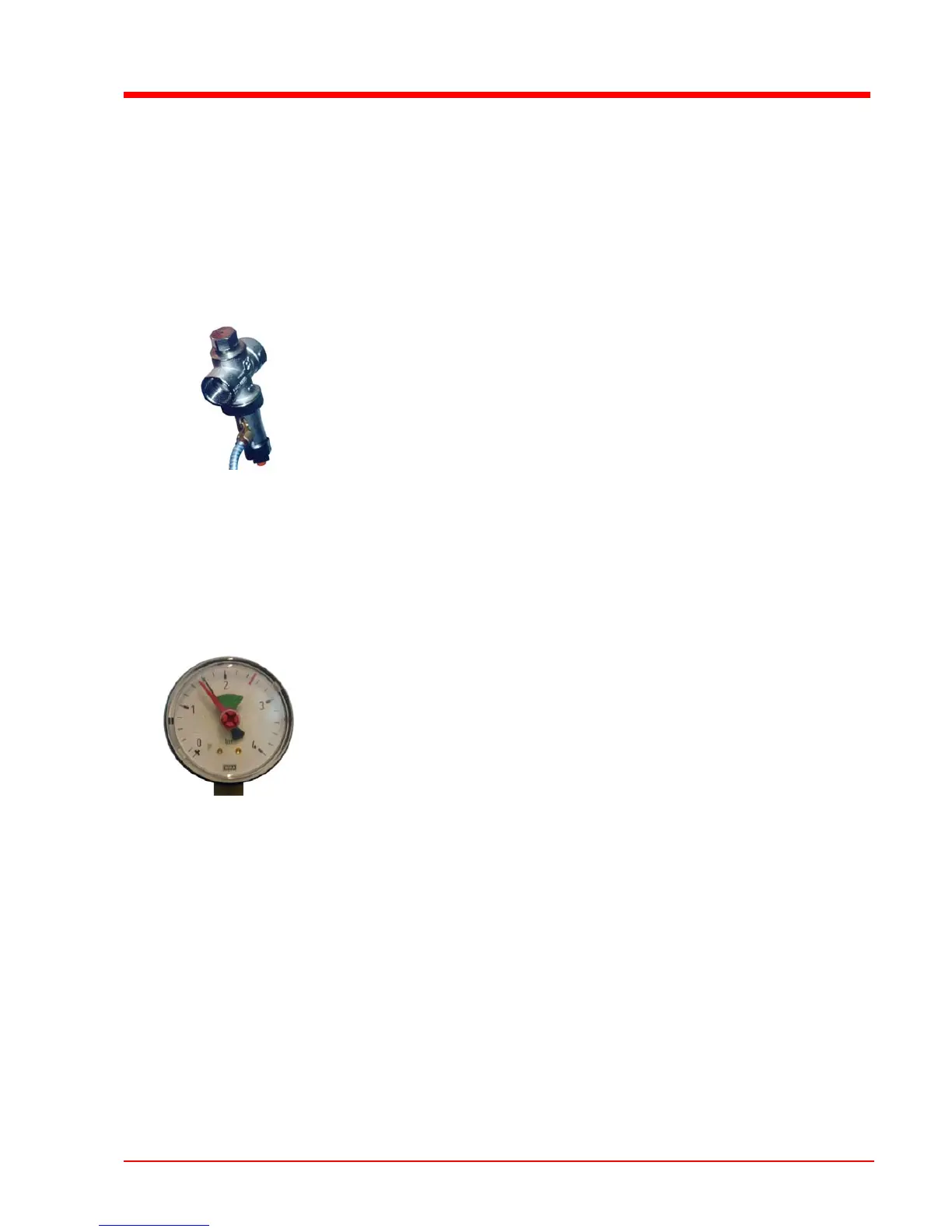

Check the system pressure

Read off the system pressure on the pressure gauge

The value must be above the pre-stressed pressure of the

expansion tank by 20%

Expansion tank operating instructions

If the system pressure decreases:

Top up the water

If this occurs frequently, the seal of the heating system is faulty!

Inform your installer!

In case of large pressure fluctuations:

Have the expansion tank checked

Check the geared motors

Carry out a visual inspection of the seal on the geared motors of the

stoker screw and ash screw

There must not be a large quantity of lubricant coming out.

If a few drops of lubricant are coming out, this can be normal. If a lot

of lubricant is being lost, inform your installer or Fröling customer

services.

Loading...

Loading...