Maintenance

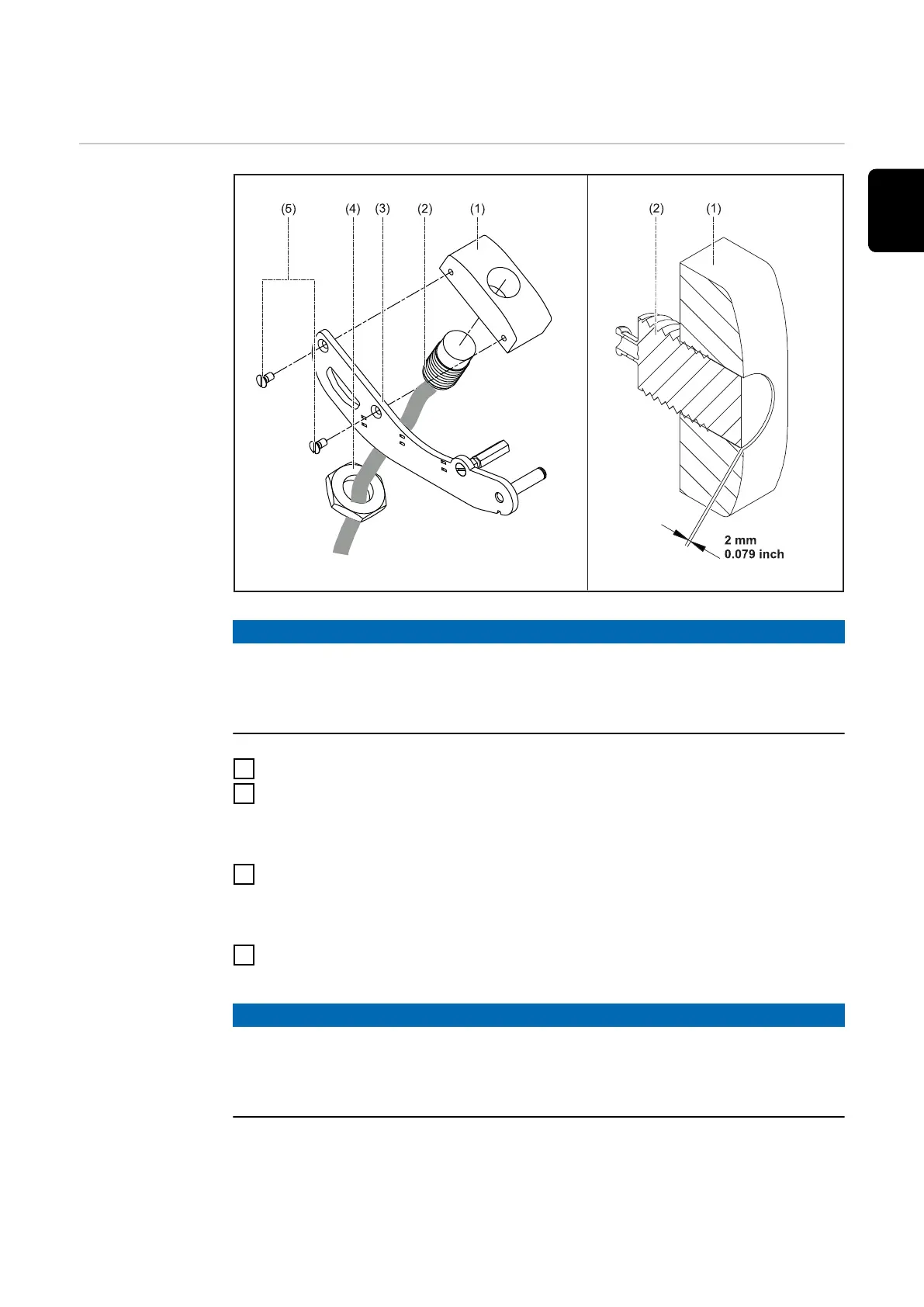

Checking that

the sensor has

been adjusted

correctly

NOTE!

Risk due to incorrect sensor setting.

Malfunctions can be the result.

▶

Check the following sensor setting after every 25th wirespool change. Adjust

or replace shoe and sensor as required.

1

Lift the retaining arm (3) and sensor unit off the wirespool and lock in place

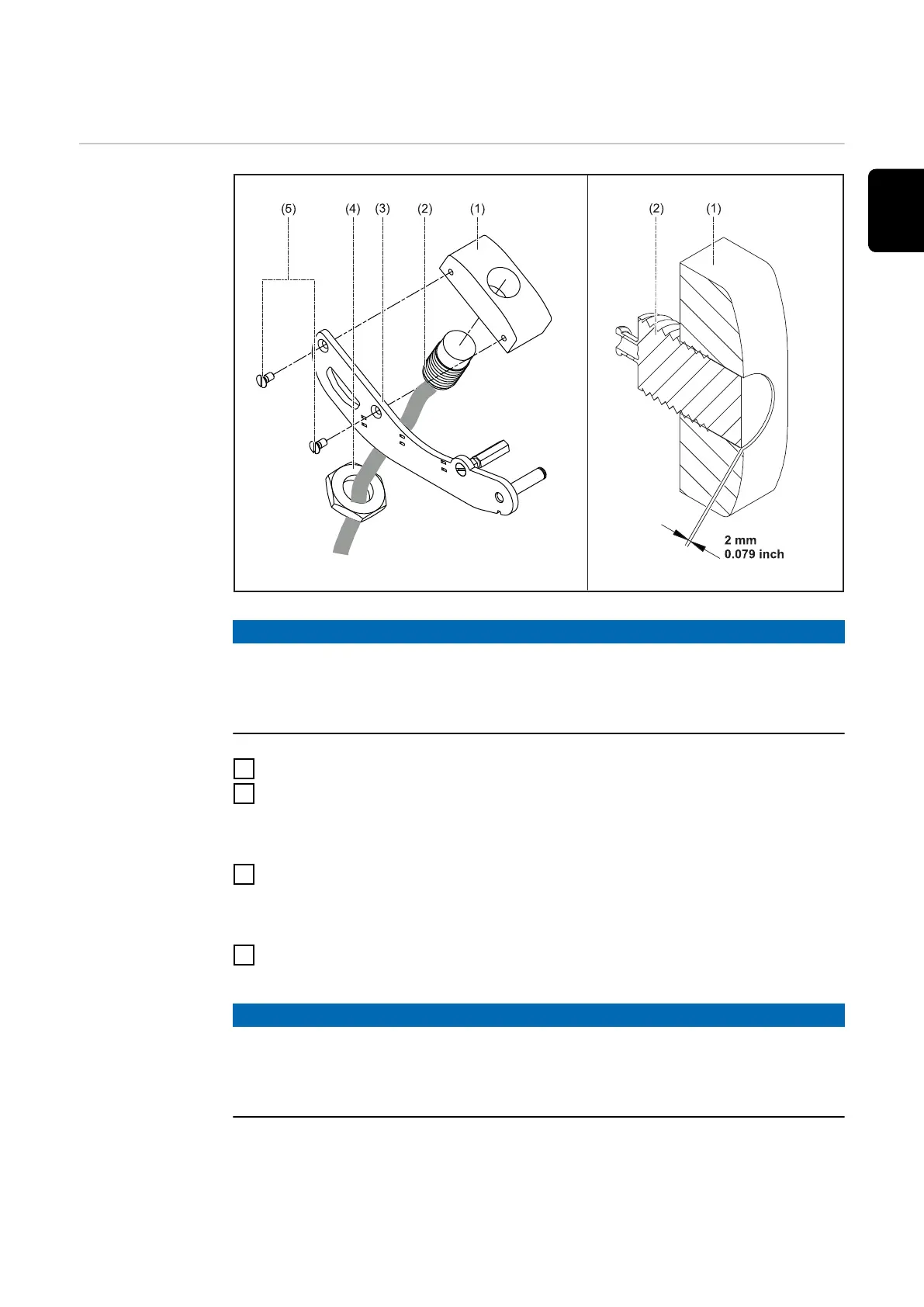

2

Using a calliper, measure the distance between the sliding surface of the

shoe (1) and the surface of the sensor (2)

If the measured distance is less than 0.5 mm (0.02 inch):

3

The gap is too small – adjust the shoe and sensor as described in the fol-

lowing section

If the measured distance is greater than 0.5 mm (0.02 in):

4

The gap is large enough - undo the retaining arm lock and ensure that the

shoe is touching the wire electrode

NOTE!

Risk due to incorrect sensor positioning.

False triggers can be the result.

▶

Make sure, the retaining arm must not touch the wirespool or the wire elec-

trode.

25

EN-US

Loading...

Loading...