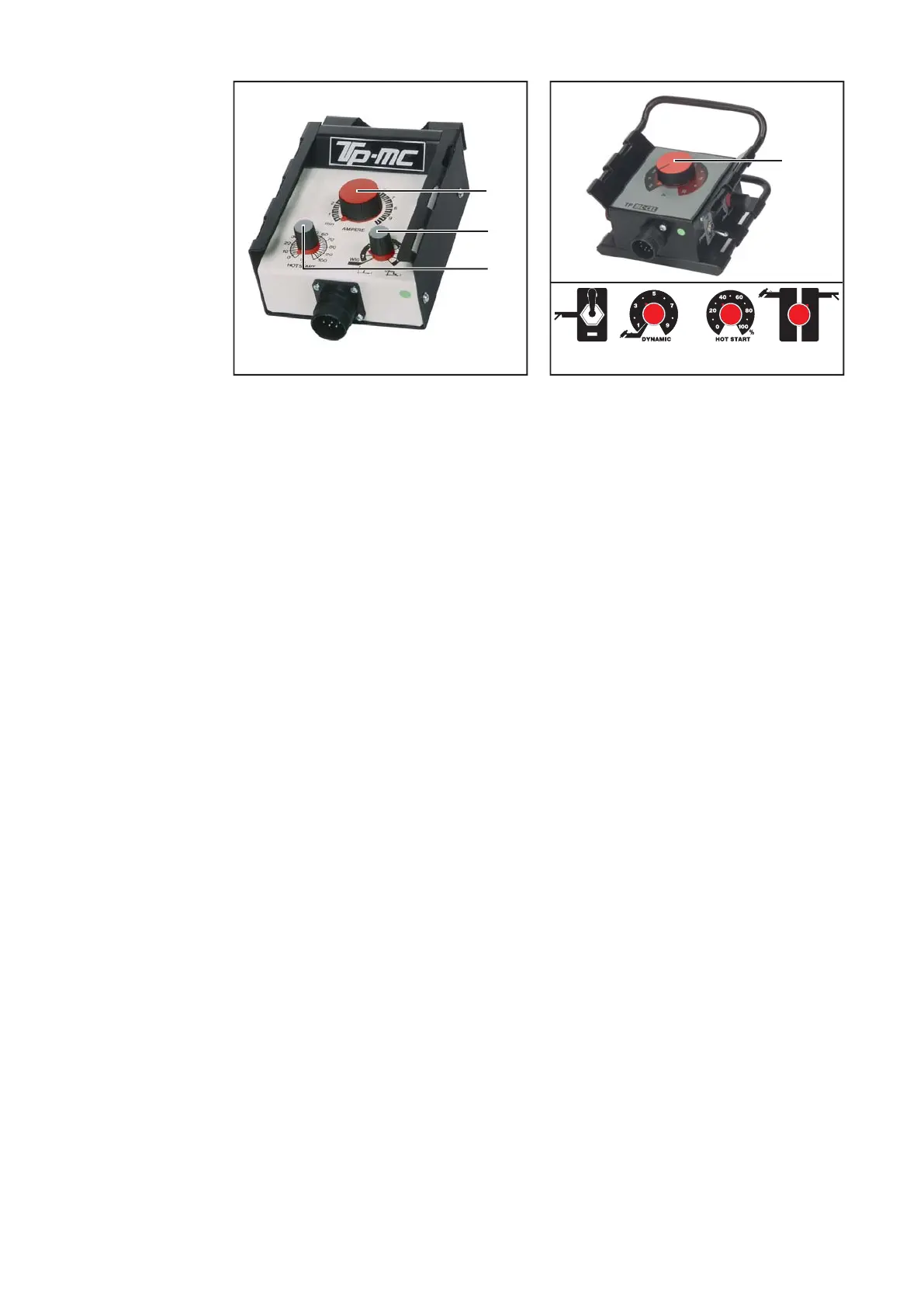

Remote control TP mc

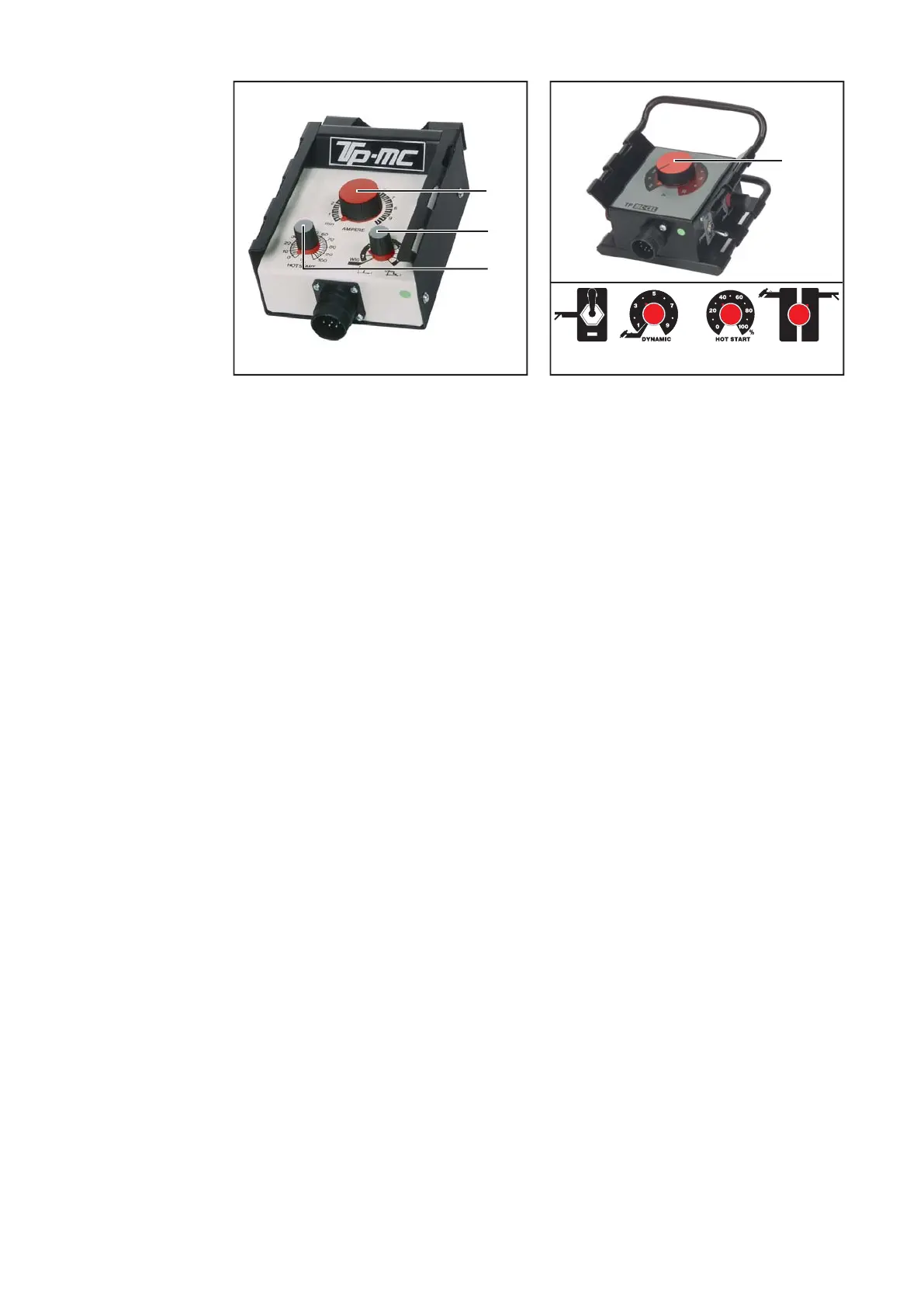

Remote control TP mc-CEL

(1) Welding current adjuster ... for stepless adjustment of the welding current

(2) Dynamic adjuster ... dYn - dynamic - dynamic correction

To obtain the best possible welding results, the arc-force dynamic will sometimes

need to be adjusted. For the setting of the "dYn" welding parameter, see the sec-

tion Select and change setup parameters.

Operating principle

At the moment of droplet transfer or in event of a short circuit, a short-term

increase in the amperage will occur. To maintain a stable arc, the welding current

temporarily rises. If the rod electrode is at risk of sinking into the weld pool, this

action prevents the weld pool from solidifying, as well as reducing the duration of

the arc's short circuit. The risk of the rod electrode sticking is therefore largely

ruled out.

Setting range of welding parameter dYn

0 ......... soft and low-spatter arc

10 ....... harder and more stable arc

(3) HotStart adjuster ... To obtain the best possible welding result, the HotStart

function will sometimes need to be adjusted.

Advantages

- Improved ignition properties, even when using electrodes with poor ignition

properties

- Better fusion of the parent material during the start-up phase, meaning fewer

cold-shut defects

- Slag inclusions largely avoided

Refer to the section "Program level preferences” for the setting of the available weld-

ing parameters.

54

Loading...

Loading...