Curtis-Toledo Rotary Compressor CAP862

Operations and Maintenance Manual

Chapter 3 Page 1

Chapter 3 General Description

COMPRESSOR

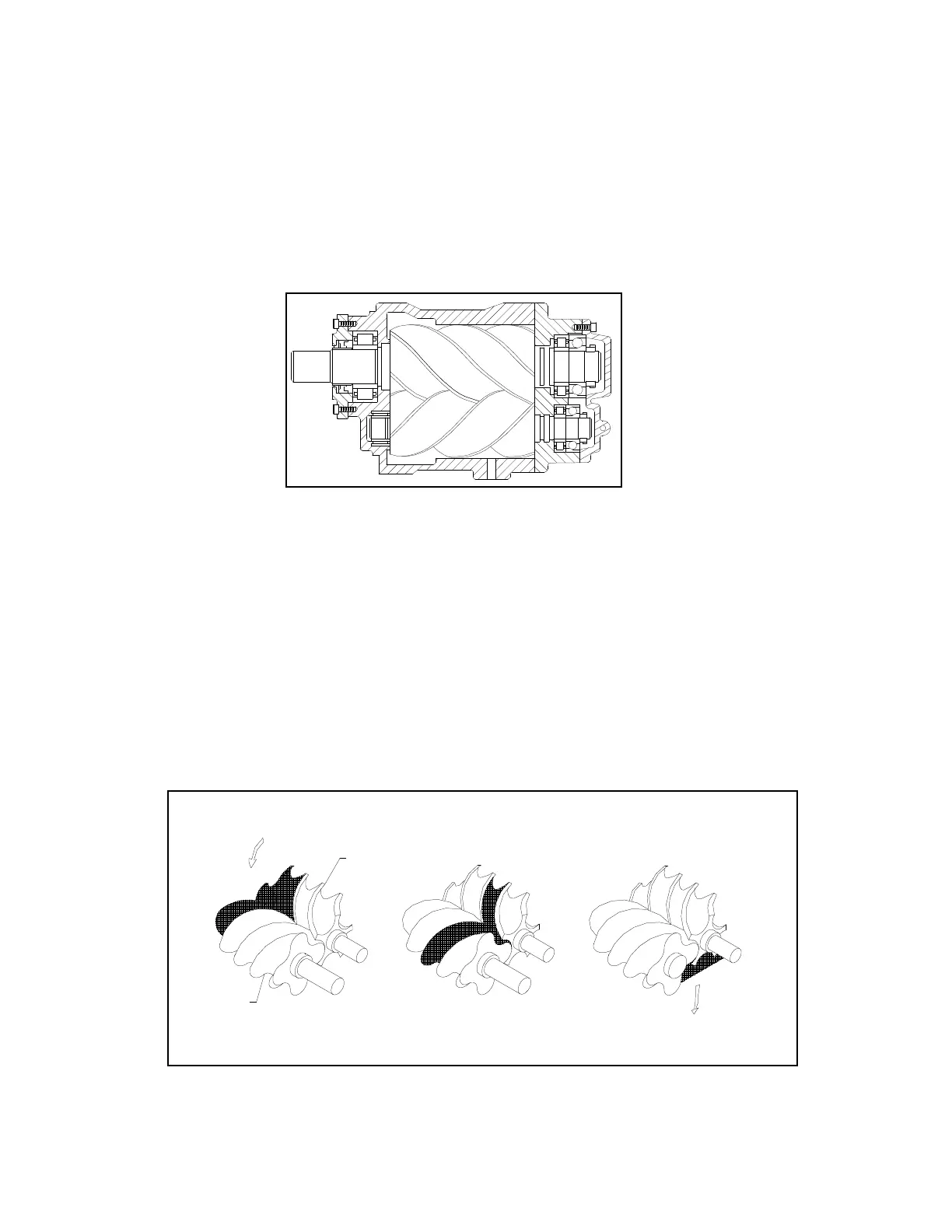

The compressor assembly is an oil flooded positive displacement, single stage, helical screw

type unit consisting of two rotors or screws supported axially by roller bearings and enclosed

in a housing or stator as depicted in the sectional view Figure 3-1.

Figure 3-1

Compressor Assembly

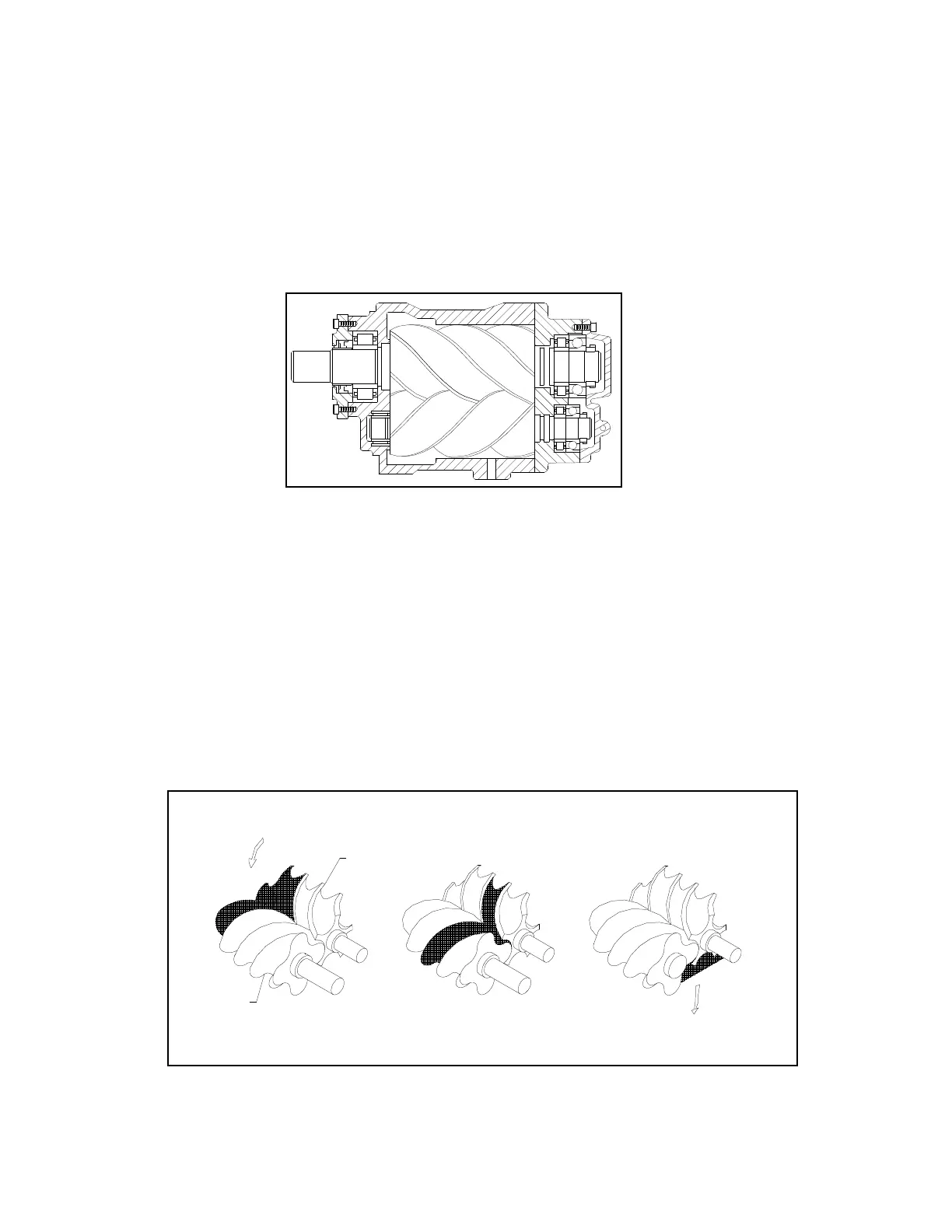

In operation as depicted below in the compression cycle (Ref. Figure 2-2), air entering the

compressor through the inlet port becomes trapped between the helical lobes of the main rotor and

the matching grooves of the secondary rotor (A). As the rotors turn air is trapped in the cavity

created by the mashing lobe and groove and reduced in volume or “compressed”. It is then pushed

through the successive cavities (B) until it reaches the discharge end of the compressor (C) and is

sent to the oil separator.

During the compressor cycle, oil is injected into the compressor for the purpose of dissipating the

heat of compression and to seal the internal clearances. The compressed air laden with oil leaves

the compressor through the discharge port and enters a reservoir where the oil and air are

separated. This process delivers a smooth flow of compressed air at the desired pressure.

Figure 2-2

Compression Cycle

INLET

DISCHARGE

MAIN ROTOR

SECONDARY

ROTOR

A B C

Loading...

Loading...